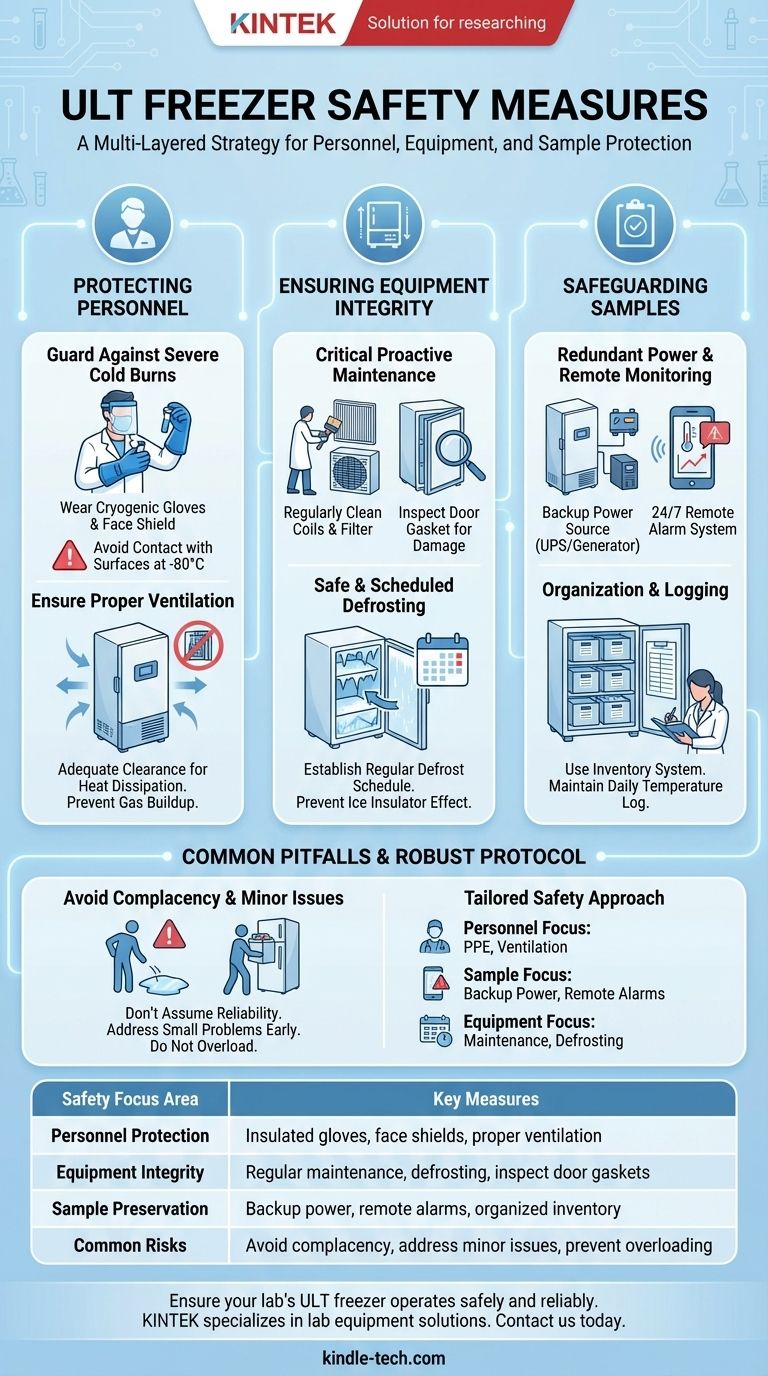

To ensure safety with an Ultra-Low Temperature (ULT) freezer, you must implement a multi-layered strategy. This involves using personal protective equipment like insulated gloves to prevent cold burns, maintaining a reliable backup power source to prevent sample loss during outages, ensuring proper ventilation around the unit, and following a strict schedule for maintenance and defrosting.

ULT freezer safety is not a single action but a complete system for managing risk. The core insight is to protect the three critical components of your work: the personnel operating the equipment, the freezer itself, and the invaluable samples stored within it.

Protecting Personnel: The First Line of Defense

The extreme temperatures of a ULT freezer, often reaching -80°C, pose a significant and immediate risk to anyone operating it.

Guarding Against Severe Cold Burns

Contact with the frozen interior surfaces or vials can cause instantaneous frostbite. Always wear cryogenic or heavily insulated gloves designed for ultra-low temperatures.

A lab coat and closed-toe shoes are mandatory. For tasks requiring extended time inside the freezer, a face shield is also recommended to protect against cold vapor and accidental splashes.

Ensuring Proper Ventilation and Placement

ULT freezers work hard to maintain their temperature, and in doing so, their compressors generate a significant amount of heat. Placing the unit in a poorly ventilated room can cause it to overheat, leading to premature failure.

Ensure there is adequate clearance around the freezer—especially at the back and top—to allow for proper air circulation and heat dissipation. This also prevents the buildup of potentially hazardous refrigerant gases in a confined space.

Ensuring Equipment Integrity and Performance

A well-maintained freezer is a safe and reliable freezer. Proactive maintenance is not optional; it is essential for preventing catastrophic failure.

The Critical Role of Proactive Maintenance

Regularly clean the condenser coils and air filter to remove dust buildup. Clogged coils force the compressor to work harder, increasing energy consumption and raising the risk of burnout.

Periodically inspect the door gasket for any cracks, brittleness, or gaps. A compromised seal allows warm, moist air to enter, which creates ice, reduces efficiency, and strains the cooling system.

Safe and Scheduled Defrosting

Ice buildup on the inner doors and cabinet walls acts as an insulator, making it harder for the freezer to maintain its set temperature. This significantly reduces efficiency and can eventually damage the door seal.

Establish a regular schedule for defrosting. This process must be done carefully, typically by temporarily moving samples to a backup freezer, to prevent temperature fluctuations that could damage them.

Safeguarding Your Irreplaceable Samples

The ultimate goal of any ULT freezer protocol is to protect the samples inside. This requires building redundancy and monitoring into your workflow.

Redundant Power and Remote Monitoring

The most common cause of catastrophic sample loss is equipment failure or a power outage. A backup power source, such as an uninterruptible power supply (UPS) connected to a generator, is your most important safety net.

Pair this with a remote alarm system. These systems monitor the freezer's internal temperature and will automatically send alerts via phone call, text, or email to designated personnel the moment a deviation occurs.

Consistent Temperature Logging

Do not rely solely on alarms. Make it a daily habit to visually check the freezer's temperature display. Maintain a temperature log to track performance over time, which can help you identify subtle downward trends that may indicate a developing mechanical issue.

The Importance of Organization

A disorganized freezer is an unsafe freezer. Every time the door is opened, the temperature rises and the system must work to cool back down.

Use a clear inventory and labeling system so you can locate samples quickly. This minimizes the time the door stays open, protecting both your samples from temperature fluctuations and the freezer from unnecessary strain.

Understanding the Common Pitfalls

Even with the best equipment, human error or complacency can undermine safety.

Complacency Is the Greatest Risk

The biggest danger is assuming the freezer will "just work." The reliability of a ULT freezer can lead to a false sense of security. Routine checks, scheduled maintenance, and consistent monitoring are non-negotiable.

Ignoring Minor Issues

A small patch of ice on a gasket or a door that doesn't seem to close as tightly as it used to can be early warning signs of a larger problem. Addressing these minor issues immediately can prevent a complete system failure down the line.

Overloading the Freezer

Placing too many items in the freezer can obstruct airflow, leading to uneven cooling and "hot spots" that can compromise samples. It also increases the strain on the cooling system, shortening its lifespan.

Implementing a Robust Safety Protocol

Your specific safety plan should be tailored to your lab's priorities and resources.

- If your primary focus is personnel safety: Prioritize providing and enforcing the use of insulated gloves and face shields, and ensure the freezer area is properly ventilated.

- If your primary focus is absolute sample preservation: Your top priority is a dual system of backup power (UPS/generator) and a 24/7 remote temperature alarm system.

- If your primary focus is equipment longevity and cost-efficiency: Create and adhere to a strict maintenance schedule for cleaning coils, inspecting gaskets, and performing regular defrosting.

A proactive approach to safety transforms your ULT freezer from a potential point of failure into a reliable guardian of your most critical assets.

Summary Table:

| Safety Focus Area | Key Measures |

|---|---|

| Personnel Protection | Use insulated gloves, face shields, ensure proper ventilation. |

| Equipment Integrity | Regular maintenance, defrosting, inspect door gaskets. |

| Sample Preservation | Backup power, remote alarms, organized inventory. |

| Common Risks | Avoid complacency, address minor issues, prevent overloading. |

Ensure your lab's ULT freezer operates safely and reliably. KINTEK specializes in lab equipment and consumables, providing robust solutions for laboratory needs. Our experts can help you select the right ULT freezer accessories, backup systems, and maintenance tools to protect your personnel and invaluable samples. Contact us today to discuss your specific requirements and enhance your lab's safety protocol!

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

People Also Ask

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- How do ultra-low temperature freezers achieve such low temperatures? The Science Behind -80°C Cooling

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency