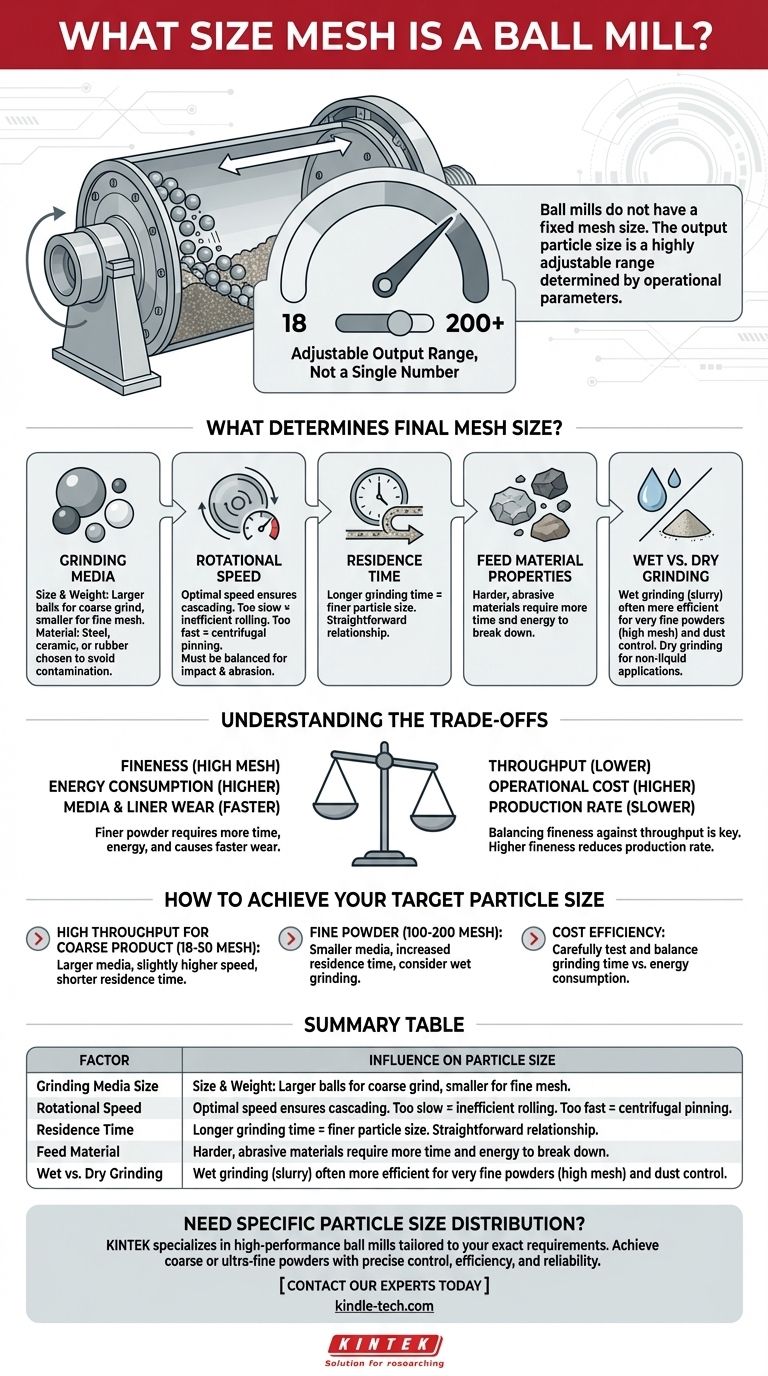

The output size of a ball mill is not a single number. Instead, it is a highly adjustable range that an operator controls to meet specific production needs. While a typical ball mill can produce an output material particle size anywhere from 18 to 200 mesh, the final result depends entirely on how the machine is configured and operated.

A ball mill doesn't have a fixed mesh size. Instead, it's a versatile grinding system where the final particle size is a direct result of operational parameters you control, not an inherent property of the machine itself.

What Determines the Final Mesh Size?

Understanding a ball mill requires seeing it as a system of variables. The final particle size is an output achieved by balancing several key factors that influence the grinding process.

The Grinding Media

The balls inside the mill are the primary tool for size reduction. Their characteristics are critical.

- Size & Weight: Larger, heavier balls (like steel) create greater impact forces, which are effective for breaking down coarse material quickly. Smaller balls create more contact points and are better for the fine grinding needed to achieve a higher mesh number.

- Material: The material of the media—steel, ceramic, or rubber—is chosen based on the material being ground to avoid contamination and to provide the right level of abrasive force.

Rotational Speed

The speed at which the mill's cylindrical shell rotates is a crucial factor.

- Too slow, and the media will simply roll over the material, resulting in inefficient grinding.

- Too fast, and centrifugal force will pin the balls to the outer wall, preventing them from tumbling and creating impact.

- The optimal speed allows the balls to be carried up the wall and then cascade down, creating the combination of impact and abrasion needed for effective grinding.

Residence Time

This is simply the amount of time the material spends inside the mill. The relationship is straightforward: the longer the material is subjected to grinding, the finer the resulting particle size will be.

Feed Material Properties

The nature of the material you are grinding has a significant impact. Harder, more abrasive materials will take longer to break down than softer or more brittle ones.

Wet vs. Dry Grinding

A ball mill can be operated with or without liquid.

- Dry grinding is a simpler process used when the material cannot be exposed to liquids.

- Wet grinding, where the material is mixed into a slurry, is often more efficient for producing very fine particles (a high mesh number) and helps control dust.

Understanding the Trade-offs

Achieving a specific mesh size isn't just a technical exercise; it's a balance of competing operational goals.

Fineness vs. Throughput

This is the most fundamental trade-off. Grinding material to a very fine powder (e.g., 200 mesh) requires significantly more time and energy than producing a coarser product (e.g., 30 mesh). As you increase the target fineness, you decrease the production rate.

Energy Consumption

Particle size reduction is an energy-intensive process. The finer the target mesh, the more energy is required per ton of material. This is a primary driver of operational cost.

Media and Liner Wear

The constant tumbling and impact of the grinding process cause wear on both the grinding balls and the mill's internal lining. More aggressive grinding—longer times, harder media, or higher speeds—accelerates this wear, leading to higher maintenance costs and downtime.

How to Achieve Your Target Particle Size

Optimizing a ball mill is about aligning its operational parameters with your end goal.

- If your primary focus is high throughput for a coarse product (e.g., 18-50 mesh): You should use larger grinding media, a slightly higher mill speed, and a shorter residence time.

- If your primary focus is producing a fine powder (e.g., 100-200 mesh): Your best approach is using smaller media, increasing the residence time, and considering wet grinding for maximum efficiency.

- If your primary focus is cost efficiency: You must carefully test and balance grinding time against energy consumption to find the most economical settings for your required particle size.

Ultimately, a ball mill's output is a direct reflection of controlled operational inputs, giving you the power to define the final product.

Summary Table:

| Factor | Influence on Particle Size |

|---|---|

| Grinding Media Size | Larger media for coarser grind; smaller media for finer grind. |

| Rotational Speed | Optimal speed ensures efficient cascading for impact and abrasion. |

| Residence Time | Longer grinding time results in finer particles. |

| Feed Material | Harder materials require more energy and time to grind finely. |

| Wet vs. Dry Grinding | Wet grinding is often more efficient for achieving very fine powders. |

Need to achieve a specific particle size distribution for your laboratory processes?

KINTEK specializes in high-performance ball mills and grinding solutions tailored to your exact requirements. Whether you need to produce a coarse 18-mesh product or an ultra-fine 200-mesh powder, our expertise ensures you get the precise control, efficiency, and reliability your lab demands.

Contact our experts today to discuss your application and discover the ideal grinding solution for your materials.

Visual Guide

Related Products

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the necessity of using an end-over-end rotator in Chlorendic Acid reduction? Ensure Kinetic Accuracy with ZVI

- Which tool could be used to pulverize an object? Match the Tool to Your Material's Hardness and Brittleness

- How does a hammer mill work step by step? Master High-Impact Particle Size Reduction

- How does high-energy dispersion equipment contribute to TiO2 composite electrolyte slurries? Optimize Ion Transport

- What are the advantages of using high-hardness steel balls as grinding media? Elevate Zirconium Hydride Synthesis

- What is the particle size of a ball mill? Control Your Grind from Microns to Nanometers

- Why is high-precision mixing and grinding equipment necessary for fluorine doping in anti-perovskite materials?

- Which method of grinding is most effective for small samples? Maximize Yield and Integrity for Precious Materials