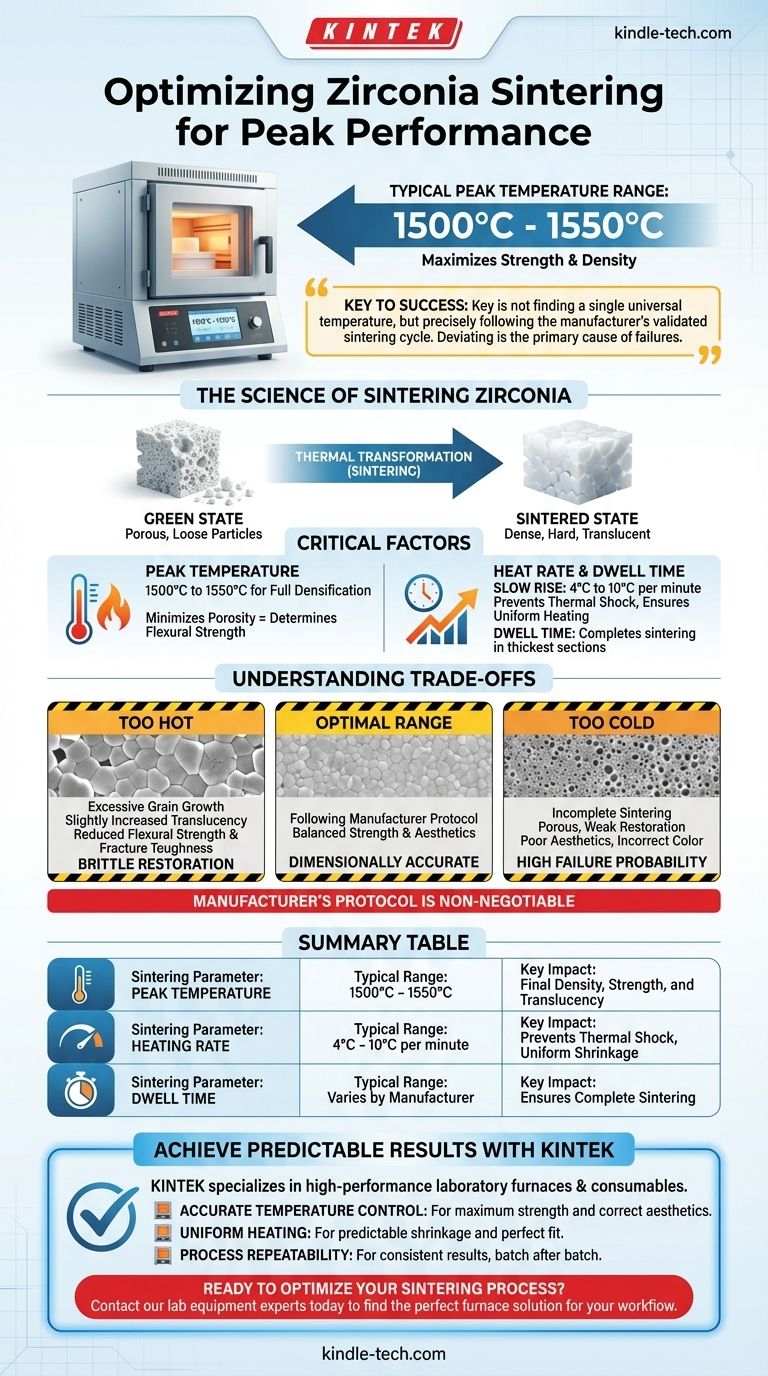

In most cases, zirconia is fired—a process more accurately called sintering—to a peak temperature between 1500°C and 1550°C. This range is where the material typically achieves its maximum strength and density. However, this is a general guideline, and the precise temperature and heating schedule are dictated entirely by the specific zirconia product and the manufacturer's instructions.

The key to success with zirconia is not finding a single universal temperature, but precisely following the manufacturer's validated sintering cycle. Deviating from this protocol is the primary cause of failures in strength, fit, and aesthetics.

The Science of Sintering Zirconia

Sintering is a process of thermal transformation. It converts the porous, chalk-like pre-sintered zirconia restoration into a dense, hard, and translucent ceramic structure. Understanding this process is key to avoiding common pitfalls.

From Porous to Dense

In its pre-sintered or "green" state, a milled zirconia restoration is composed of loosely packed ceramic particles. The sintering cycle applies controlled heat, causing these particles to bond and fuse together, eliminating the spaces between them and shrinking the restoration to its final, dense form.

Why Temperature Dictates Strength

The peak temperature of the sintering cycle is directly linked to the final density of the material. Studies show that reaching the 1500°C to 1550°C range is critical for most conventional zirconia types (like 3Y-TZP) to achieve full densification. This process minimizes porosity, which is the primary factor in determining the material's final flexural strength and fracture resistance.

The Critical Role of Heat Rate and Dwell Time

Sintering is not just about the peak temperature. The rate of temperature increase is equally important. Most manufacturers specify a slow heat rise, typically between 4°C and 10°C per minute. A slow, controlled ramp-up prevents thermal shock and ensures the entire restoration heats uniformly, which is crucial for predictable shrinkage and preventing internal stress.

Once at peak temperature, the restoration is held for a period—known as the dwell time—to ensure the sintering process is completed throughout the thickest parts of the crown or bridge.

Understanding the Trade-offs

Slightly altering the sintering cycle can have significant and often detrimental effects on the final restoration. Simply aiming for a "hotter" or "faster" cycle is a common mistake.

The "Too Hot" Problem: Grain Growth

Exceeding the manufacturer's recommended peak temperature can cause excessive grain growth within the zirconia's crystal structure. While this may slightly increase translucency, it often comes at the cost of reduced flexural strength and fracture toughness, making the restoration more brittle.

The "Too Cold" Problem: Incomplete Sintering

Firing at a temperature below the recommended range is even more problematic. If the zirconia does not reach its ideal sintering temperature, it will not fully densify. This results in a porous, weak restoration with poor aesthetics, incorrect color, and a high probability of premature failure.

The Manufacturer's Protocol is Non-Negotiable

Different zirconia formulations (e.g., high-strength posterior vs. high-translucency anterior) have unique chemical compositions. Each manufacturer invests significant resources to develop a validated sintering protocol that perfectly balances strength, translucency, and dimensional accuracy for their specific material. Using the protocol for "Zirconia A" with a puck of "Zirconia B" will lead to unpredictable and substandard results.

Achieving Predictable Results Every Time

Your goal is to eliminate variables and produce consistent, high-quality outcomes. The key lies in precision and adherence to a validated process.

- If your primary focus is maximum strength and durability: Strictly adhere to the manufacturer's standard sintering cycle, ensuring your furnace is calibrated to accurately reach the target peak temperature (often 1500-1550°C).

- If your primary focus is high aesthetics and translucency: Use a zirconia material specifically designed for anterior use and follow its unique sintering protocol, which may use a slightly different peak temperature or cycle time.

- If you are experiencing inconsistent results (e.g., poor fit, low strength, off-shades): Your first action should be to verify and calibrate your furnace's temperature and then meticulously re-confirm you are using the correct cycle for the exact zirconia puck in use.

Ultimately, mastering zirconia is a discipline of precision, not approximation.

Summary Table:

| Sintering Parameter | Typical Range | Key Impact |

|---|---|---|

| Peak Temperature | 1500°C - 1550°C | Determines final density, strength, and translucency. |

| Heating Rate | 4°C - 10°C per minute | Prevents thermal shock and ensures uniform shrinkage. |

| Dwell Time | Varies by Manufacturer | Ensures complete sintering through the thickest sections. |

Achieve consistent, high-quality zirconia restorations with every sintering cycle.

Your success depends on precise temperature control and repeatable processes. KINTEK specializes in high-performance laboratory furnaces and consumables, providing dental labs with the reliable equipment needed to follow manufacturer protocols exactly.

We help you eliminate variables and ensure:

- Accurate Temperature Control: For maximum strength and correct aesthetics.

- Uniform Heating: For predictable shrinkage and perfect fit.

- Process Repeatability: For consistent results, batch after batch.

Ready to optimize your sintering process? Contact our lab equipment experts today to find the perfect furnace solution for your specific zirconia materials and workflow.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What does a porcelain furnace do? Create Durable, Aesthetic Dental Restorations

- What is the temperature of a porcelain furnace? Master Sintering for Perfect Results

- What is the effect of high speed sintering on zirconia? Dramatically Faster Cycles with Critical Trade-offs

- What type of zirconia is most commonly used in dentistry? Choose Between Strength and Aesthetics

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- Why is kaolin used for crown teeth? The Key Ingredient for Shaping Strong, Natural-Looking Porcelain

- What are the advantages of zirconia bridges? A Durable, Metal-Free Solution for a Natural Smile