Fundamentally, plasma deposition is valued for being a low-temperature process, often allowing for substrate temperatures ranging from near room temperature (20-25°C) up to a few hundred degrees Celsius. However, the concept of a single "temperature" in a plasma is misleading. The effective temperature on your substrate is a controllable variable, not a fixed property of the process itself.

The defining advantage of plasma-enhanced chemical vapor deposition (PECVD) is its ability to deposit high-quality films at low substrate temperatures. This is possible because chemical reactions are driven by high-energy plasma electrons, not by high ambient heat, decoupling the film growth process from the thermal limits of your substrate.

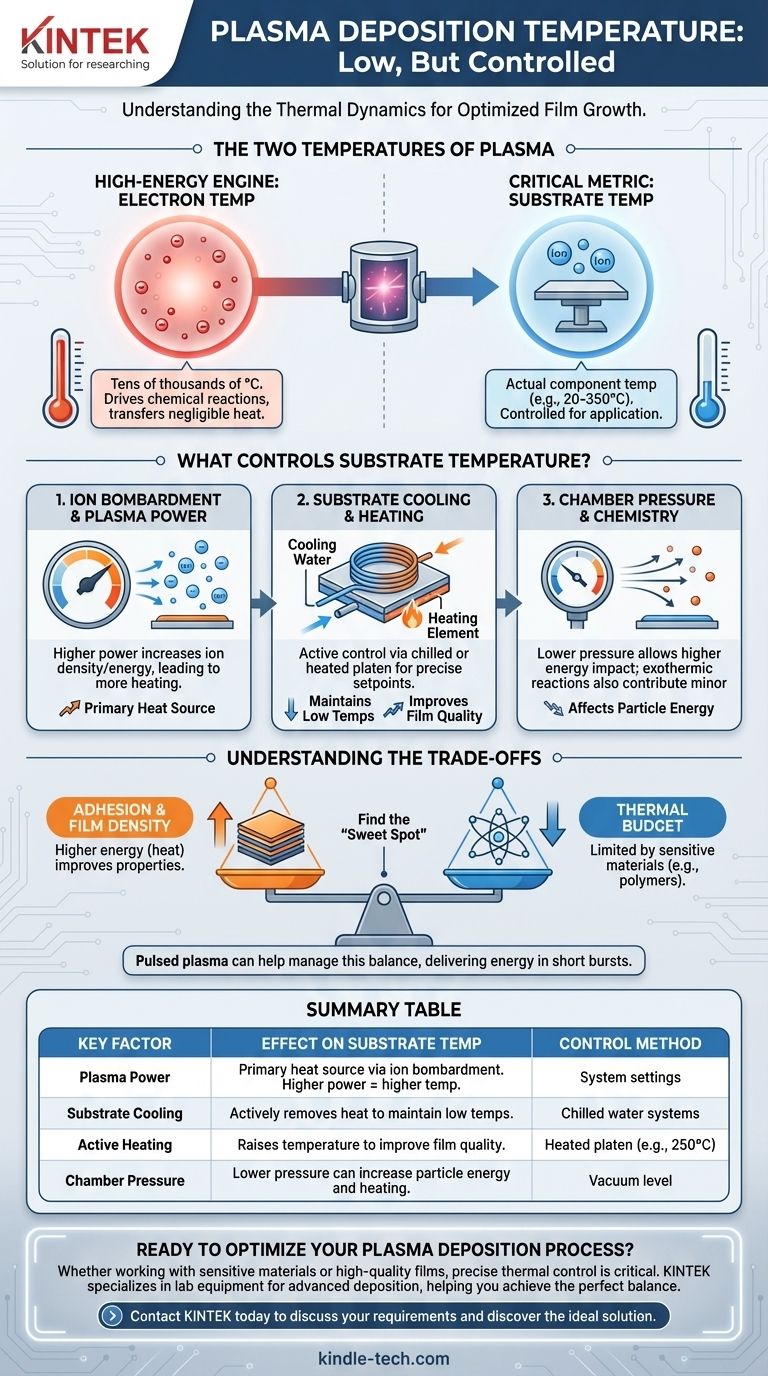

The Two Temperatures of Plasma

To understand why this process is suitable for temperature-sensitive materials, you must distinguish between the two different "temperatures" co-existing within the plasma chamber. They are radically different and have different effects.

The High-Energy Engine: Electron Temperature

Plasma is a gas of ionized particles, containing positive ions and free electrons. To create and sustain the plasma, energy is pumped into the system, which is almost entirely absorbed by these low-mass electrons.

This gives them an extremely high electron temperature, often equivalent to tens of thousands of degrees Celsius (several electron-volts, eV). However, because electrons have negligible mass, they transfer very little heat energy when they collide with your substrate.

Their critical role is to collide with the precursor gas molecules, breaking them down into highly reactive species (radicals). These reactive species are what ultimately form the film.

The Critical Metric: Substrate Temperature

This is the actual temperature your component or material will experience during the deposition. This temperature is much, much lower than the electron temperature and is the value that matters for your application.

The substrate temperature is not a passive property but the result of several competing heating and cooling mechanisms within the deposition chamber.

What Controls the Substrate Temperature?

The ability to control substrate temperature is what makes plasma deposition so versatile. The final temperature is a balance of several key factors that you can manipulate.

Ion Bombardment and Plasma Power

While electrons don't transfer much heat, positive ions do. These heavier particles are accelerated towards the substrate and, upon impact, convert their kinetic energy into thermal energy, causing heating.

Increasing the plasma power directly increases the density and/or energy of these ions, leading to a higher rate of heating. This is the most significant source of heat input onto the substrate.

Substrate Cooling and Heating

Modern deposition systems have a platen (or "stage") on which the substrate sits. This stage is almost always equipped with active temperature control.

It can be actively cooled with chilled water or other means to keep temperatures low, even at high plasma powers. Conversely, it can be actively heated to a specific setpoint (e.g., 250°C) to improve film density, reduce stress, or enhance surface chemistry.

Chamber Pressure and Gas Chemistry

Process pressure influences the energy of particles hitting the substrate. At lower pressures, particles travel further without collision and can strike the surface with higher energy.

Furthermore, some chemical reactions on the substrate surface are exothermic, meaning they release heat and can contribute to a minor increase in the overall substrate temperature.

Understanding the Trade-offs

While "low temperature" is the headline feature, it's essential to understand the practical limitations and choices involved.

The "Low Temperature" Misconception

"Low temperature" is a relative term. While it is far lower than traditional thermal CVD (which can exceed 800°C), an uncooled plasma process can still easily reach 100-300°C just from the energy of ion bombardment.

If your substrate is a sensitive polymer with a glass transition temperature of 80°C, you cannot simply assume the process will be cold enough. You must ensure the system has adequate cooling.

Adhesion vs. Thermal Budget

There is often a direct trade-off between film quality and substrate temperature. Higher energy ion bombardment (which increases temperature) can improve film density and adhesion.

Optimizing a process involves finding the "sweet spot" that provides the necessary film properties without exceeding the thermal budget of your substrate. Pulsing the plasma is one advanced technique used to manage this, delivering energy in short bursts to allow for cooling in between.

Making the Right Choice for Your Goal

Your ideal process temperature is dictated entirely by your material and desired film properties. Use the following as a guide.

- If your primary focus is depositing on sensitive polymers or biological materials: Prioritize a process with low plasma power, potentially pulsed plasma, and ensure your equipment has robust substrate cooling to maintain near-room temperatures.

- If your primary focus is high-quality optical or electronic films: A moderately elevated temperature (e.g., 150-350°C) is often required to achieve the desired film density, refractive index, and low stress, so active heating and precise control are key.

- If your primary focus is dense, durable hard coatings (like DLC): You will likely use higher-power processes that generate more heat, but the final temperature will still be significantly lower than that of competing non-plasma methods.

By understanding and controlling these factors, you can tailor the plasma deposition process to meet the precise thermal constraints of your application.

Summary Table:

| Key Factor | Effect on Substrate Temperature | Typical Range / Control Method |

|---|---|---|

| Plasma Power | Primary heat source via ion bombardment. Higher power = higher temperature. | Controlled via system settings. |

| Substrate Cooling | Actively removes heat to maintain low temperatures. | Chilled water or other cooling systems. |

| Active Heating | Raises temperature to improve film quality. | Heated platen with precise setpoints (e.g., 250°C). |

| Chamber Pressure | Lower pressure can increase particle energy and heating. | Controlled vacuum level. |

Ready to Optimize Your Plasma Deposition Process?

Whether you are working with temperature-sensitive polymers or need high-quality films for electronics, precise thermal control is critical. KINTEK specializes in lab equipment and consumables for advanced deposition processes, helping you achieve the perfect balance between film quality and substrate integrity.

Let our experts help you:

- Select the right system with optimal cooling and heating capabilities.

- Fine-tune your process parameters for your specific materials.

- Ensure reliable, repeatable results for your R&D or production needs.

Contact KINTEK today to discuss your plasma deposition requirements and discover the ideal solution for your laboratory.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques