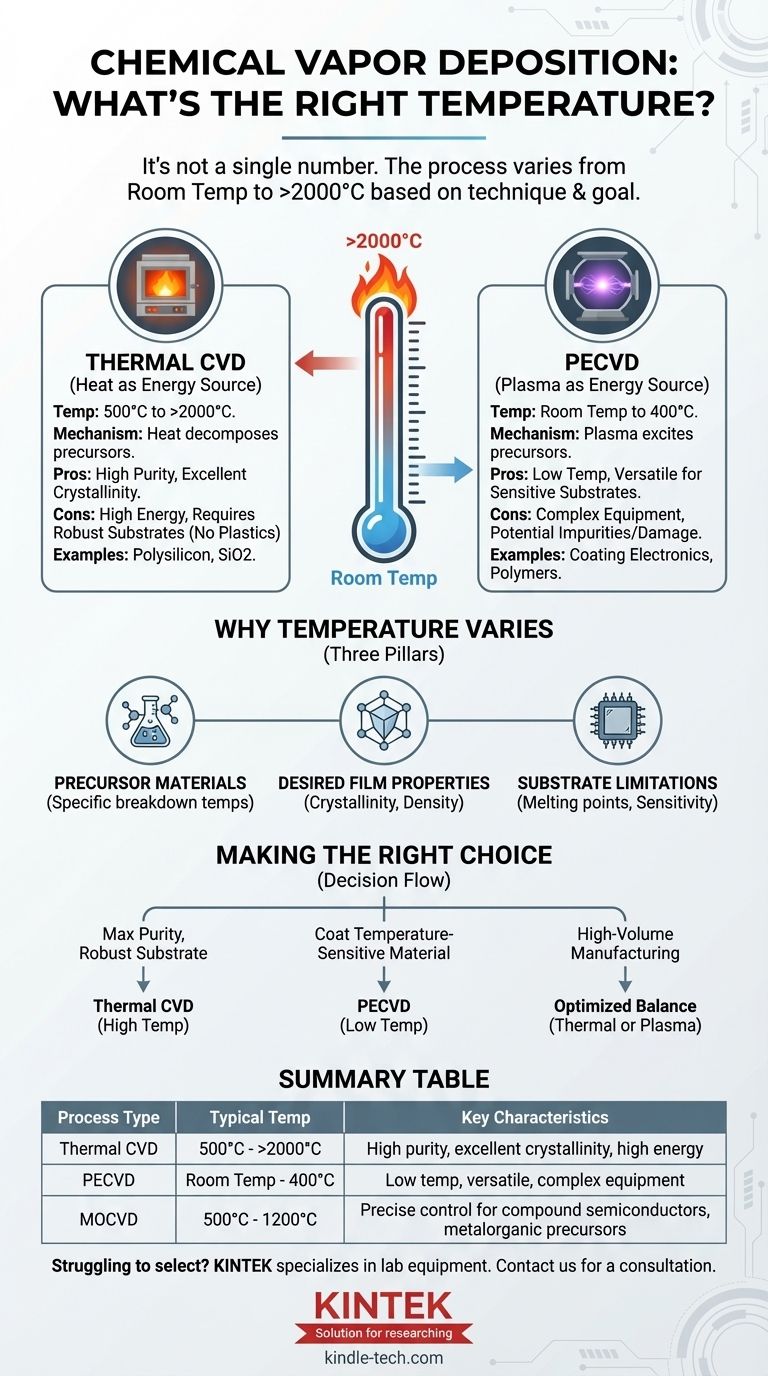

There is no single temperature for chemical vapor deposition (CVD). The process temperature varies dramatically based on the specific technique, the precursor materials used, and the desired properties of the final film. This range can span from near room temperature for plasma-assisted methods to well over 2000°C for high-purity thermal processes.

The core principle of CVD is providing enough energy to initiate a chemical reaction on a substrate's surface. While high temperature is a common way to supply this energy, it is not the only way. Understanding the trade-offs between different energy sources is key to selecting the right process.

The Role of Energy in CVD

Chemical vapor deposition is not a single process but a family of techniques. They all share one goal: to use precursor gases to deposit a solid thin film onto a surface. The "best" temperature is simply the one that provides the right amount of energy for the specific chemical reaction required.

Heat as the Primary Energy Source (Thermal CVD)

Traditional CVD relies on heat to drive the reaction. The substrate is placed in a chamber and heated to a temperature high enough to cause the precursor gases to decompose and react, forming a solid layer on the surface.

This is the principle behind Thermal CVD, Hot-Filament CVD, and Metalorganic CVD (MOCVD). These methods are often used to create highly pure, crystalline films like the polysilicon used in solar cells or silicon dioxide in microelectronics.

Plasma as an Alternative Energy Source (PECVD)

Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a major advancement that allows for deposition at much lower temperatures. Instead of relying solely on heat, an electric field is used to excite the precursor gases into a plasma state.

This highly energetic plasma provides the energy needed for the chemical reaction to occur. Because the energy comes from the plasma rather than thermal heating of the substrate, the process can run at significantly lower temperatures, often from room temperature to a few hundred degrees Celsius.

Why Temperature Varies So Widely

The required temperature for a CVD process is not an arbitrary number; it's determined by a precise set of physical and chemical constraints.

The Precursor Materials

Every chemical compound has a specific temperature at which it begins to break down or react. The choice of precursor gas is the first factor that dictates the necessary temperature window.

The Desired Film Properties

Temperature directly influences the final properties of the deposited film. Higher temperatures often lead to denser, more crystalline films with higher purity. Lower temperatures might result in an amorphous (non-crystalline) structure, which can be desirable for certain applications.

The Substrate's Limitations

Perhaps the most important practical constraint is the substrate material. You cannot deposit a film at 900°C onto a plastic substrate that melts at 150°C. The need to coat temperature-sensitive materials, like completed electronic circuits or polymers, is a primary driver for using low-temperature PECVD methods.

Understanding the Trade-offs

The choice between a high-temperature and low-temperature process is a critical engineering decision based on a clear set of trade-offs.

High-Temperature CVD (e.g., Thermal CVD)

- Pros: Typically produces films with very high purity and excellent crystalline quality. The process is often simpler and more controlled for fundamental materials research.

- Cons: Extremely high energy consumption and requires substrates that can withstand intense heat. This process is unsuitable for coating finished electronics or plastics.

Low-Temperature CVD (e.g., PECVD)

- Pros: Highly versatile, enabling the coating of temperature-sensitive materials. It can also achieve higher deposition rates for certain materials, increasing manufacturing throughput.

- Cons: The equipment is more complex. The plasma environment can sometimes introduce impurities or cause damage to the film, and the resulting film quality may be different (e.g., less crystalline) than its high-temperature equivalent.

Making the Right Choice for Your Goal

To determine the appropriate temperature, you must first define your objective. The "right" CVD process is the one that achieves your desired film properties without damaging the substrate.

- If your primary focus is maximum purity and crystallinity on a robust substrate: A high-temperature thermal CVD process is the conventional and often superior choice.

- If your primary focus is coating a temperature-sensitive material: A low-temperature PECVD process is not just an option, it is a necessity.

- If your primary focus is high-volume manufacturing (e.g., solar cells or protective coatings): The decision involves a complex balance of deposition rate, energy cost, and final film performance, leading to highly optimized thermal or plasma systems.

Ultimately, your goal dictates the process, and the process dictates the temperature.

Summary Table:

| CVD Process Type | Typical Temperature Range | Key Characteristics |

|---|---|---|

| Thermal CVD | 500°C to >2000°C | High purity, excellent crystallinity, high energy use |

| PECVD | Room Temp to 400°C | Low temp, versatile for sensitive substrates, more complex equipment |

| MOCVD | 500°C to 1200°C | Precise control for compound semiconductors, uses metalorganic precursors |

Struggling to select the right CVD process for your specific substrate and film requirements? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the trade-offs between high-temperature and low-temperature techniques to achieve your desired film properties—whether it's maximum purity on a robust substrate or coating a temperature-sensitive material. Contact our team today for a personalized consultation and discover the ideal CVD solution for your research or production goals.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity