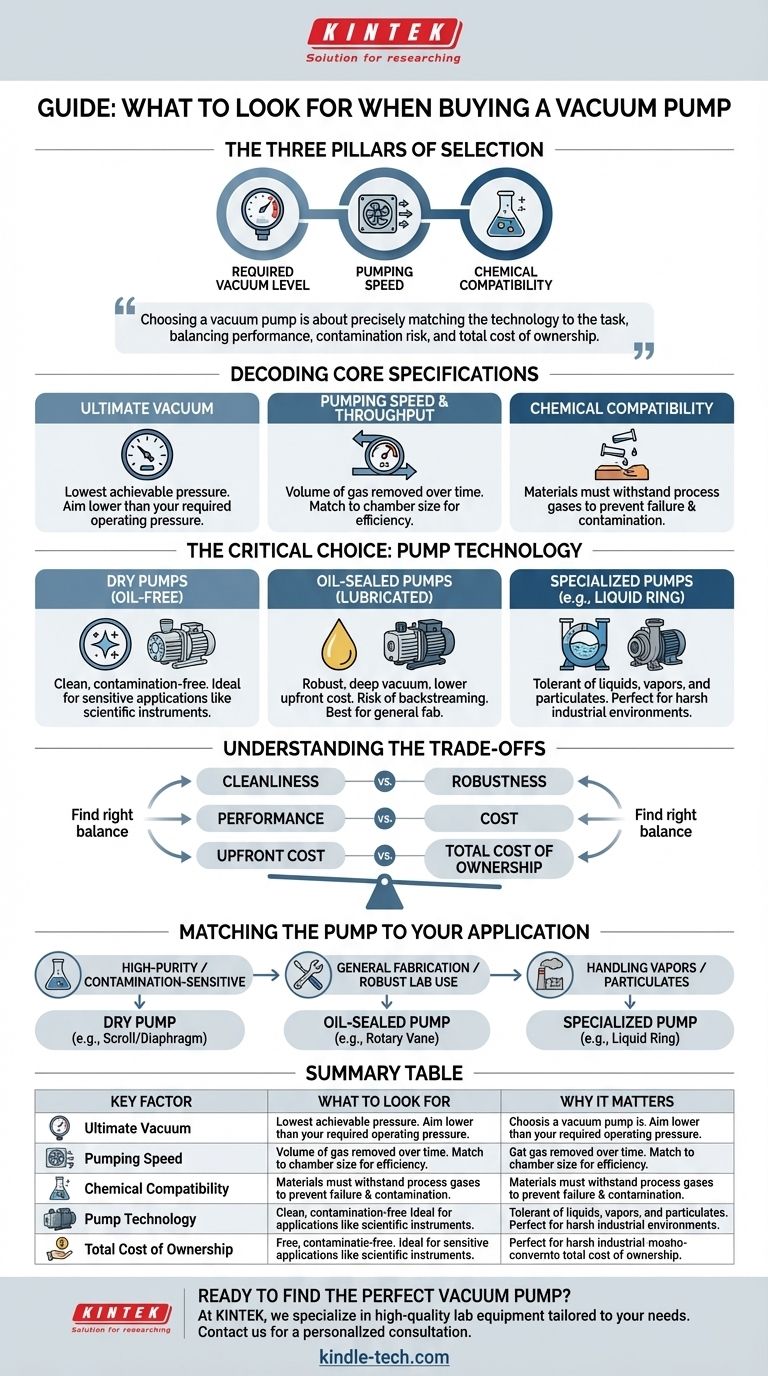

When buying a vacuum pump, the most critical factors to evaluate are the required vacuum level, the pumping speed needed for your chamber size, and the chemical compatibility of the pump's materials with the substances you intend to pump. These three pillars will guide your selection and ensure the pump is both effective and durable for your specific application.

Choosing a vacuum pump is not about finding the "strongest" model, but about precisely matching the technology to the task. The right choice balances performance requirements against the risk of contamination and the total cost of ownership over the pump's lifetime.

Decoding the Core Specifications

To make an informed decision, you must first understand the language of vacuum technology. These core specifications define a pump's capabilities and its suitability for your process.

Ultimate Vacuum & Operating Pressure

The ultimate vacuum (or ultimate pressure) is the lowest pressure a pump can achieve in a sealed system under ideal conditions. It represents the maximum "emptiness" the pump can create.

Your application will have a required operating pressure, which is the specific vacuum level you need to maintain for your process to work correctly. Always choose a pump with an ultimate vacuum significantly lower than your required operating pressure.

Pumping Speed & Throughput

Pumping speed is the volume of gas the pump can remove from a chamber per unit of time, often measured in liters per minute (l/m) or cubic meters per hour (m³/h). A larger chamber requires a higher pumping speed to evacuate in a reasonable time.

Throughput is the mass of gas the pump can handle over time. Think of it this way: pumping speed is how fast you can bail water out of a boat, while throughput is how much water you are actually removing.

Chemical Compatibility

This is a non-negotiable factor for safety and pump longevity. The materials inside the pump (seals, diaphragms, oil) must be able to withstand the specific gases and vapors from your process without degrading.

Ignoring chemical compatibility can lead to catastrophic pump failure, system contamination, and hazardous leaks. Always verify that the pump's wetted parts are compatible with your process chemicals.

The Critical Choice: Pump Technology

The most fundamental decision is the type of pump technology, which primarily comes down to whether it uses oil.

Dry vs. Oil-Sealed (Lubricated) Pumps

Dry pumps use mechanisms like diaphragms or scrolls that do not require oil for sealing or lubrication. This makes them ideal for applications where contamination from oil vapor would ruin a process, such as in scientific instruments or food processing.

Oil-sealed pumps, most commonly rotary vane pumps, are robust, efficient, and can often achieve deeper vacuum levels for a lower upfront cost. They are workhorses in general fabrication and industrial settings but require regular oil changes and risk "backstreaming" oil vapor into the vacuum chamber.

Specialized Pumps (e.g., Liquid Ring)

For very specific and harsh industrial environments, you may need a specialized design. A liquid ring pump, for example, uses a ring of centrifuged liquid (often water) to create its seal.

These pumps are exceptionally tolerant of liquids, vapors, and even small solid particles, making them perfect for demanding applications like distilleries, power plants, and chemical processing where other pumps would quickly fail.

Understanding the Trade-offs

Selecting a vacuum pump always involves balancing competing priorities. Understanding these trade-offs is the key to making a wise investment.

Cleanliness vs. Robustness

The central trade-off is often between a dry pump and an oil-sealed pump. A dry pump offers clean, oil-free operation but may be more sensitive to moisture or high temperatures. An oil-sealed pump is more resilient and often more efficient but introduces the risk of contamination and requires more maintenance.

Performance vs. Cost

As with most equipment, higher performance—meaning a deeper ultimate vacuum and faster pumping speed—comes at a higher price. Over-specifying a pump is a common mistake that wastes capital. Define your required performance first, then select the most economical pump that meets it.

Upfront Cost vs. Total Cost of Ownership

The initial purchase price is only part of the story. Consider the total cost of ownership, which includes maintenance (oil, seals), potential downtime, and energy consumption. A cheaper oil-sealed pump might become more expensive over time than a reliable dry pump due to frequent oil changes and lost productivity.

Matching the Pump to Your Application

Use your primary goal to guide your final decision.

- If your primary focus is high-purity or contamination-sensitive work: Choose a dry scroll or diaphragm pump with proven chemical compatibility for your process gases.

- If your primary focus is general fabrication or robust lab use: An oil-sealed rotary vane pump offers the best balance of performance, durability, and cost.

- If your primary focus is handling large volumes of vapor or particulates: A specialized pump, such as a liquid ring model, is designed for this exact purpose and will provide the most reliable service.

Making the right choice ensures your process runs reliably and efficiently from day one.

Summary Table:

| Key Factor | What to Look For | Why It Matters |

|---|---|---|

| Ultimate Vacuum | Lower than your required operating pressure | Ensures the pump can achieve and maintain the vacuum level your process needs |

| Pumping Speed | Matches your chamber size for efficient evacuation | Determines how quickly the pump can remove gas from your system |

| Chemical Compatibility | Pump materials resistant to your process gases/vapors | Prevents pump failure, contamination, and safety hazards |

| Pump Technology | Dry (oil-free) vs. Oil-Sealed vs. Specialized (e.g., Liquid Ring) | Balances cleanliness, robustness, and suitability for harsh environments |

| Total Cost of Ownership | Includes maintenance, downtime, and energy costs | Provides a true picture of long-term investment beyond the initial price |

Ready to find the perfect vacuum pump for your lab?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific needs. Our experts will help you select a vacuum pump that delivers the right balance of performance, durability, and cost-effectiveness for your application.

Contact us today for a personalized consultation and ensure your process runs reliably and efficiently!

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the purpose of the vacuum pump? A Key Tool for Controlling Process Environments

- What are the parts of a kiln sitter? A Guide to the Essential Safety Mechanism

- Why is a heating magnetic stirrer essential for ZnO nanoparticle synthesis? Achieve Precision in Material Engineering

- What is the technical significance of selecting hardened stainless steel grinding balls? Optimize Energy and Purity

- Why use fluoroelastomer seals for ball milling halide electrolytes? Ensure Pure LiCl and ZrCl4 Synthesis

- What is the function of a magnetic stirrer in MoO3/GO composite prep? Master Molecular Homogenization and Nucleation

- Why are a K-type thermocouple and a temperature regulator necessary for stainless steel heat treatment? Master Precision

- Why is a gas ballast valve necessary on a rotary vane vacuum pump? Protect Your Oil and Extend Pump Life