In short, pyrolysis is most effective for plastics that are difficult or uneconomical to recycle through traditional mechanical means. This includes mixed plastic streams, multi-layer packaging, and plastics contaminated with other materials. The process is particularly well-suited for a category of plastics known as polyolefins.

Pyrolysis offers a powerful solution for converting low-value plastic waste into valuable resources like oil and gas. The key is understanding that while many plastics can be processed, the type and quality of the input directly determine the efficiency of the process and the quality of the output.

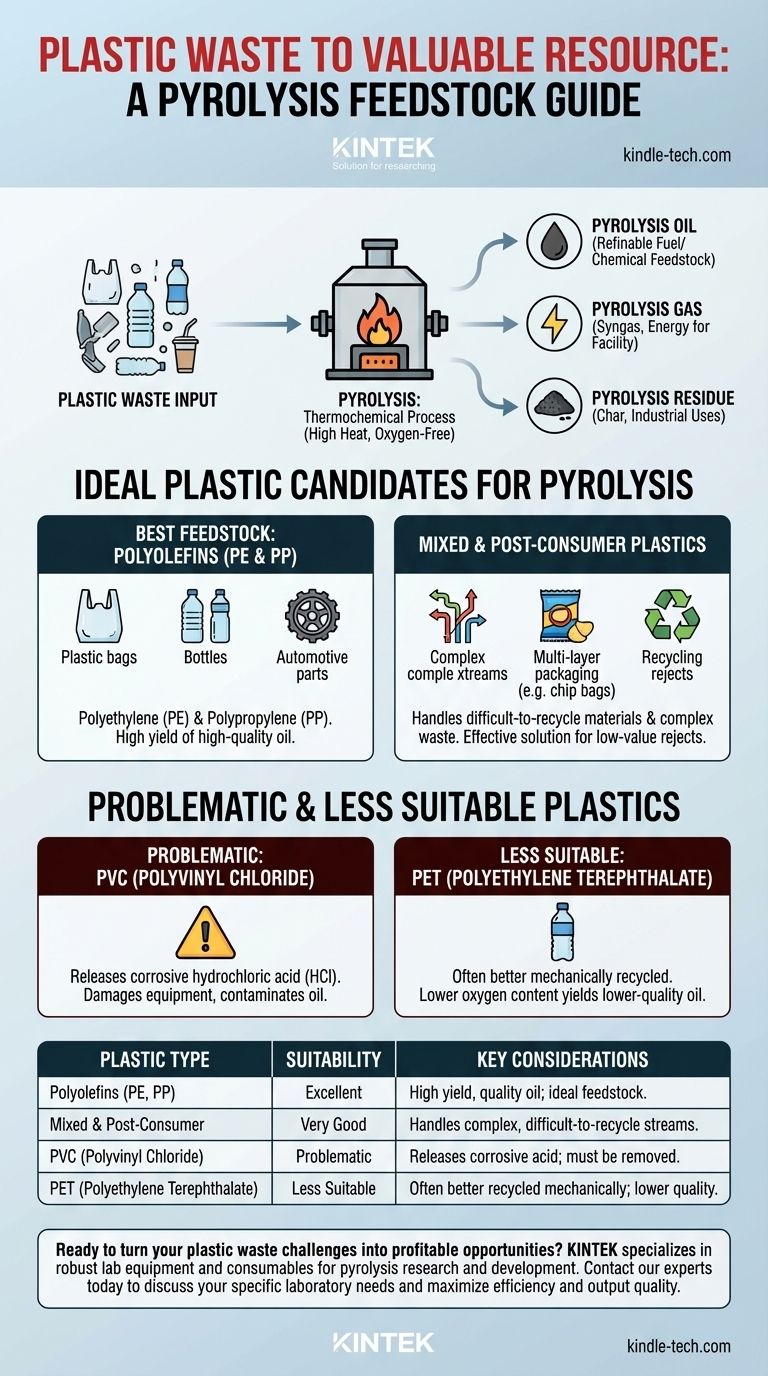

The Role of Pyrolysis in Plastic Waste Management

Pyrolysis is a thermochemical process. It uses high heat in an oxygen-free environment to break down the long, complex polymer chains that make up plastics into smaller, simpler molecules.

An "Un-Baking" Analogy

Think of it as the reverse of baking. When you bake a cake, you combine simple ingredients (flour, sugar, eggs) with heat to create a complex final product. Pyrolysis takes a complex product (plastic) and applies heat to break it back down into its simpler, more basic constituents.

The Target: Difficult-to-Recycle Plastics

The primary advantage of pyrolysis is its ability to handle plastic streams that defeat traditional recycling. This includes materials that are often landfilled or incinerated.

The Outputs: From Waste to Value

The process converts plastic waste into three main products:

- Pyrolysis Oil: A synthetic crude oil that can be refined into fuels or used as a chemical feedstock.

- Pyrolysis Gas (Syngas): A mixture of combustible gases that can be used to power the pyrolysis facility itself, making it more energy-efficient.

- Pyrolysis Residue (Char): A solid, carbon-rich byproduct that can have various industrial applications.

Ideal Plastic Candidates for Pyrolysis

While many types of plastic can be processed, some are far more suitable than others based on the quality and yield of the oil they produce.

Polyolefins (PE & PP): The Best Feedstock

Plastics like Polyethylene (PE)—used in plastic bags, bottles, and films—and Polypropylene (PP)—found in containers and automotive parts—are the ideal candidates. They yield a high quantity of high-quality pyrolysis oil.

Mixed and Post-Consumer Plastics

This is where pyrolysis truly shines. It can effectively process post-consumer plastics and segregated municipal solid waste (MSW). These streams are often a mix of different polymer types.

Low-Value Recycling Rejects

Materials that are rejected from mechanical recycling facilities due to contamination or complex composition, such as multi-layer packaging (e.g., chip bags), are excellent candidates for pyrolysis.

Understanding the Trade-offs and Problematic Plastics

Not all plastics are created equal, and some introduce significant challenges into the pyrolysis process. Acknowledging these limitations is critical for a successful operation.

The Major Issue with PVC (Polyvinyl Chloride)

PVC is highly problematic. When heated, the chlorine in its structure is released, forming hydrochloric acid. This acid is extremely corrosive to equipment and contaminates the final oil product, reducing its value and requiring extra processing steps.

The Challenge with PET (Polyethylene Terephthalate)

PET, commonly used for water bottles, can be pyrolyzed. However, it is often more economically and environmentally valuable to recycle it through traditional mechanical means. Furthermore, its oxygen content can lead to lower-quality oil compared to polyolefins.

The Impact of Contaminants

Any non-plastic material or moisture in the feedstock will affect the process. Moisture will turn to steam and may result in wastewater that needs treatment, while other contaminants will simply increase the amount of solid residue (char).

How to Apply This to Your Goal

Your choice of plastic feedstock should be directly aligned with your primary objective.

- If your primary focus is maximizing high-quality fuel oil yield: Prioritize clean streams of Polyethylene (PE) and Polypropylene (PP).

- If your primary focus is waste management for complex streams: Pyrolysis is an excellent solution for mixed plastics, multi-layer packaging, and rejects from mechanical recycling.

- If your primary focus is operational safety and equipment longevity: Invest in pre-sorting technology to remove as much PVC as possible from your feedstock before it enters the reactor.

By correctly matching the plastic input to the process capabilities, pyrolysis can effectively transform problematic waste into a valuable resource.

Summary Table:

| Plastic Type | Suitability for Pyrolysis | Key Considerations |

|---|---|---|

| Polyolefins (PE, PP) | Excellent | High yield of quality oil; ideal feedstock. |

| Mixed & Post-Consumer Plastics | Very Good | Handles complex, difficult-to-recycle streams. |

| PVC (Polyvinyl Chloride) | Problematic | Releases corrosive hydrochloric acid; must be removed. |

| PET (Polyethylene Terephthalate) | Less Suitable | Often better recycled mechanically; yields lower-quality oil. |

Ready to turn your plastic waste challenges into profitable opportunities? KINTEK specializes in providing robust lab equipment and consumables for pyrolysis research and development. Whether you're analyzing feedstock suitability or optimizing your process, our solutions help you maximize efficiency and output quality. Contact our experts today to discuss how we can support your specific laboratory needs and help you achieve your waste-to-resource goals.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Does heat treatment increase the strength of a material? Tailor Your Material's Properties

- What type of plastic is usually used with compression molding and transfer molding? Master Thermosets for Superior Performance

- How does heat affect material strength? Understanding Thermal Degradation and Creep Failure

- How sustainable is selective laser sintering? Weighing Material Waste vs. Energy Use

- What are the benefits of staying updated with the latest ULT freezer technologies? Save Costs & Boost Sustainability

- What technical objectives are addressed using batch test equipment? Optimize Heavy Metal Adsorption Research

- What is the difference between cold type and hot type? Uncover the Printing Revolution

- Why is precise temperature control critical for nanoporous zirconia membranes? Master Phase Stability & Yield