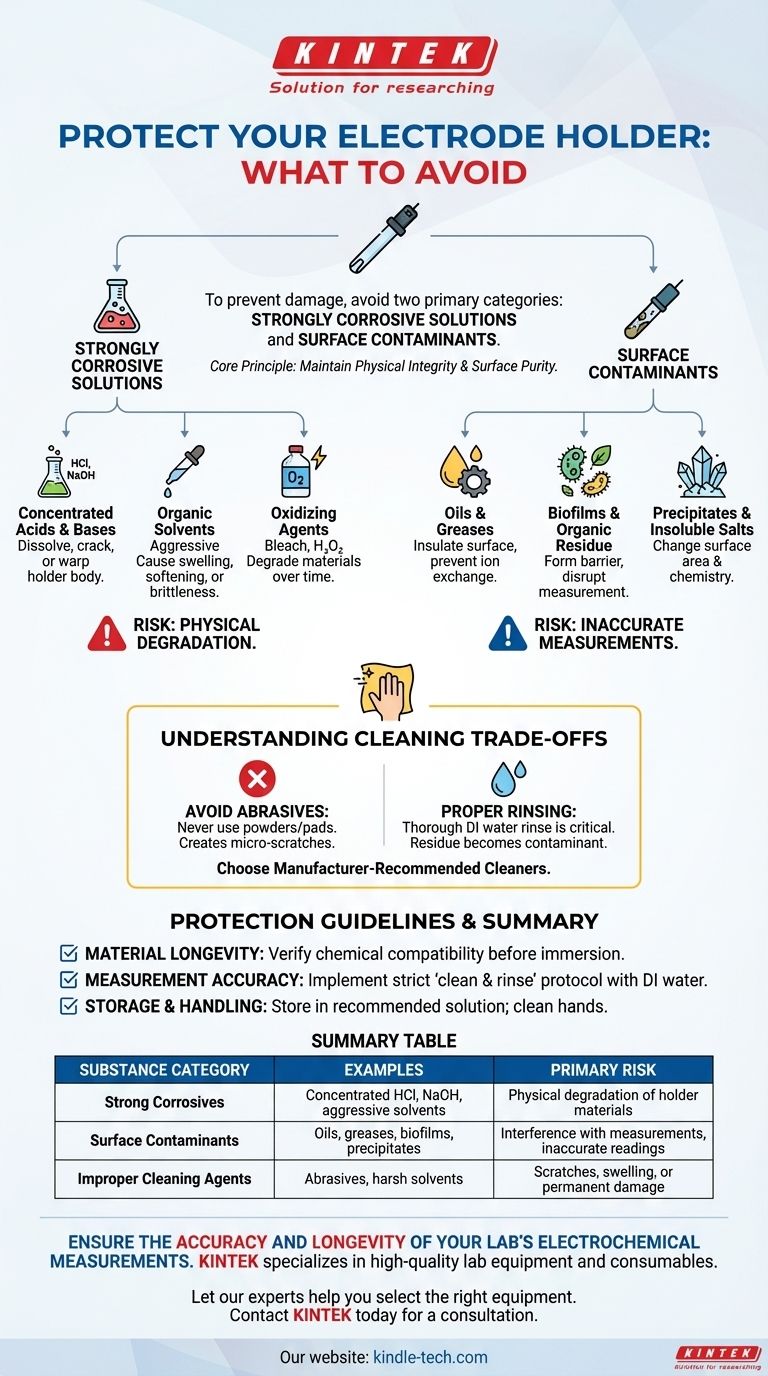

To prevent damage to an electrode holder, you must avoid two primary categories of substances: strongly corrosive solutions and any substance that can contaminate the electrode surface. Corrosives like concentrated hydrochloric acid will physically degrade the holder's materials, while contaminants can interfere with the electrochemical reactions, leading to inaccurate measurements.

The core principle of electrode holder care is maintaining both its physical integrity and the purity of its measurement surface. Anything that chemically attacks the holder's materials or leaves a residue on the electrode itself compromises your results and the longevity of your equipment.

Why Material Integrity and Purity Are Critical

An electrode holder's function is twofold: to securely position the electrode and to ensure a clean, isolated connection for accurate readings. When foreign substances are introduced, both of these functions are put at risk. This leads to faulty data, equipment failure, and potential safety hazards.

The Threat of Corrosive Agents

Corrosive substances directly attack and degrade the materials of the electrode holder, which are often composed of specific polymers or metals chosen for their chemical resistance and insulating properties.

Concentrated Acids and Bases: Strong acids, such as concentrated hydrochloric acid (HCl) or sulfuric acid (H₂SO₄), and strong bases like sodium hydroxide (NaOH) can rapidly dissolve, crack, or warp the holder's body.

Organic Solvents: Aggressive organic solvents can also cause damage. They may not "corrode" in the traditional sense but can cause polymers to swell, soften, or become brittle, compromising the holder's structural integrity.

Oxidizing Agents: Strong oxidizers, including bleach (sodium hypochlorite) or hydrogen peroxide, can also degrade holder materials over time, leading to premature failure.

The Problem of Surface Contamination

Contamination is a more subtle but equally damaging issue. It occurs when a substance adheres to the electrode surface, interfering with the electrochemical measurements.

Oils and Greases: These non-conductive substances can coat the electrode, effectively insulating it from the solution being measured. This blockage prevents accurate ion exchange, leading to slow response times or completely erroneous readings.

Biofilms and Organic Residue: In biological or environmental applications, microorganisms can form a biofilm on the electrode surface. This layer acts as a barrier, disrupting the measurement process.

Precipitates and Insoluble Salts: If you are working with solutions near their saturation point, salts can precipitate onto the electrode surface. This buildup changes the active surface area and chemistry of the electrode, skewing results.

Understanding the Trade-offs: Cleaning vs. Contamination

While cleaning is necessary, the cleaning process itself can introduce risks if not performed correctly. Aggressive cleaning can be just as damaging as the initial contamination.

The Risk of Abrasives

Never use abrasive powders or scouring pads to clean an electrode holder or the electrode itself. Physical scouring creates micro-scratches on the surface, which can trap future contaminants and may permanently damage the sensitive electrode tip.

The Danger of Improper Rinsing

After cleaning with a recommended detergent or solution, thorough rinsing with deionized (DI) water is critical. Any residual cleaning agent left on the surface becomes a contaminant in your next measurement.

Choosing the Right Cleaning Agent

Always consult the manufacturer's guidelines for your specific electrode. Using an incompatible cleaner, like a harsh solvent on a plastic body, will cause irreversible damage. When in doubt, mild detergents and DI water are the safest starting point.

How to Protect Your Electrode Holder

Protecting your equipment is a matter of establishing correct lab procedures. Follow these guidelines to ensure the longevity and accuracy of your electrode systems.

- If your primary focus is material longevity: Always verify the chemical compatibility of your sample solution with the holder's materials before immersion, especially when working with concentrated or non-aqueous solutions.

- If your primary focus is measurement accuracy: Implement a strict "clean and rinse" protocol between every measurement, using deionized water and approved cleaning solutions to remove any potential surface contaminants.

- If your primary focus is storage and handling: Always store the electrode in the recommended storage solution and ensure hands are clean and free of oils or lotions before handling the equipment.

By treating your electrode holder with the same care as the sensitive electrode it protects, you ensure the reliability of your data and the long-term performance of your entire measurement system.

Summary Table:

| Substance Category | Examples | Primary Risk |

|---|---|---|

| Strong Corrosives | Concentrated HCl, NaOH, aggressive solvents | Physical degradation of holder materials |

| Surface Contaminants | Oils, greases, biofilms, precipitates | Interference with measurements, inaccurate readings |

| Improper Cleaning Agents | Abrasives, harsh solvents not recommended by manufacturer | Scratches, swelling, or permanent damage |

Ensure the accuracy and longevity of your lab's electrochemical measurements.

KINTEK specializes in high-quality lab equipment and consumables. Our range of compatible electrode holders and cleaning solutions is designed to withstand demanding laboratory environments, providing reliable performance and protecting your investment.

Let our experts help you select the right equipment for your specific applications.

Contact KINTEK today for a consultation and to learn more about our products tailored to your laboratory needs.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Button Battery Case for Battery Lab Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable XRD Sample Holders for Diverse Research Applications

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

People Also Ask

- How is a high-precision electrolytic cell used to evaluate metal corrosion resistance? Validate DCT Results Accurately

- What is the difference between electrolytic corrosion cell and electrochemical corrosion cell? Understand the Driving Force Behind Corrosion

- How is a three-electrode electrochemical electrolytic cell utilized to evaluate Zr-Nb alloy corrosion resistance?

- What are the advantages of a flat electrochemical cell for corrosion? Achieve Precise Pitting & Crevice Analysis

- How does a three-electrode electrolytic cell function? Precision Testing for 8620 Steel in Corrosive Environments