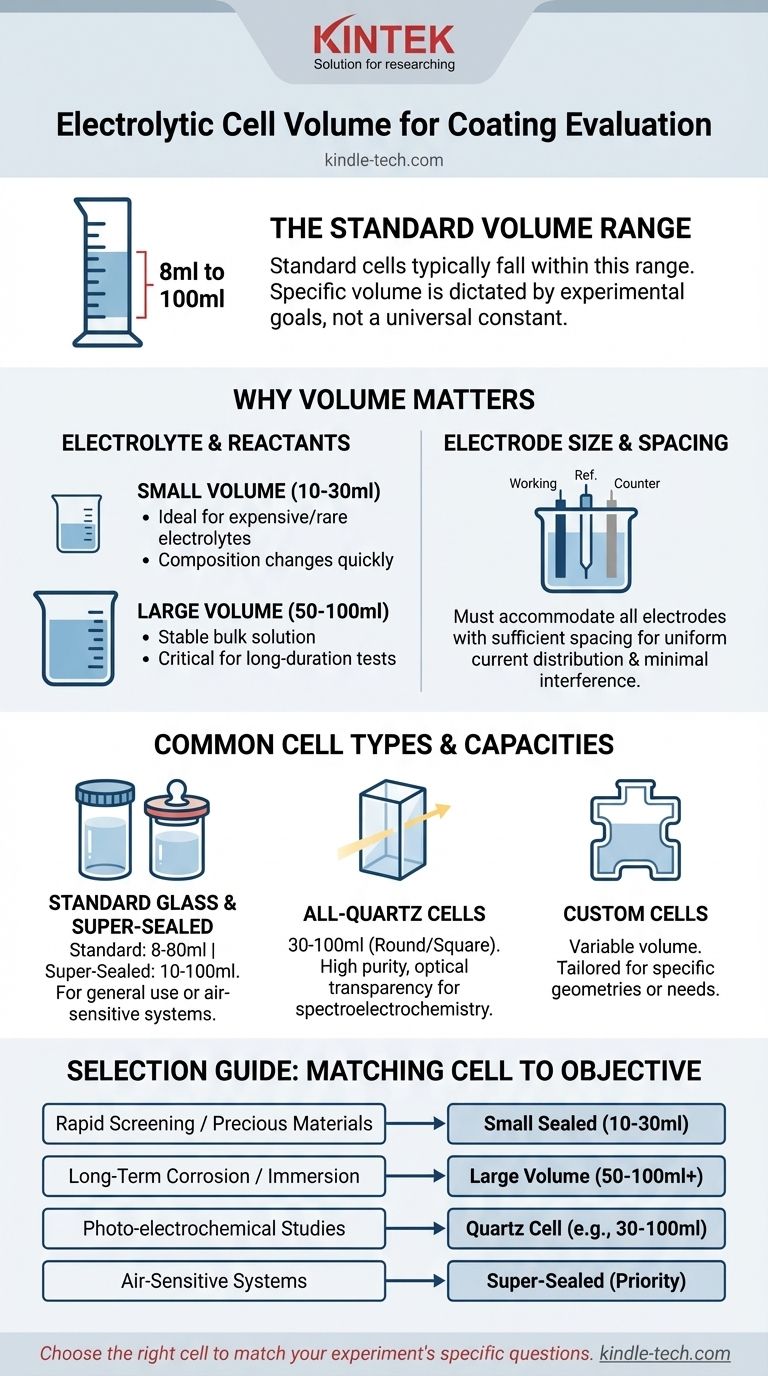

For coating evaluation, the volume of a standard electrolytic cell typically ranges from 8ml to 100ml. This range covers the most common glass and super-sealed cell types used in three-electrode electrochemical systems. However, specialized cells, such as those made from quartz or custom-fabricated for specific experiments, can extend beyond these standard volumes.

The specific volume you require is not a standalone number, but a parameter dictated by your experimental goals. The choice depends less on a universal "correct" volume and more on the type of test, the materials involved, and whether you need to control the cell's atmosphere or perform optical measurements.

Why Cell Volume Is a Critical Parameter

The volume of the electrolytic cell directly influences the conditions of your experiment. It's a fundamental choice that affects the consumption of materials, the stability of the test environment, and the physical constraints of your setup.

The Impact on Electrolyte and Reactants

A smaller volume cell (e.g., 10-30ml) is ideal when working with expensive or rare electrolytes, as it minimizes material cost. However, the chemical composition of this small volume can change quickly as the reaction proceeds.

Conversely, a larger volume cell (e.g., 50-100ml) provides a more stable bulk solution. This is critical for long-duration immersion tests, such as corrosion studies, where you want to minimize changes in electrolyte concentration over hours or days.

The Relationship with Electrode Size

The cell must be large enough to comfortably accommodate the three-electrode system—the working electrode (your coated sample), a reference electrode, and a counter electrode.

There must be sufficient space between electrodes to prevent electrical field interference and to ensure a uniform current distribution across the surface of the working electrode, which is essential for accurate coating evaluation.

Common Cell Types and Their Volumes

Electrolytic cells are not one-size-fits-all. The material and design of the cell are just as important as the volume, and different types offer different standard capacities.

Standard and Super-Sealed Glass Cells

These are the workhorses of many electrochemistry labs. Standard cells often range from 8ml to 80ml.

Super-sealed cells, which typically range from 10ml to 100ml, are designed with airtight lids. This is crucial for coating evaluation experiments that are sensitive to oxygen or require a controlled inert gas atmosphere (e.g., by purging with nitrogen or argon).

All-Quartz Cells

Quartz cells are used for specialized applications, primarily spectroelectrochemistry, where you need to shine light through the cell to monitor changes in the coating.

Unsealed, round quartz cells are commonly available in volumes like 30ml, 50ml, and 100ml. Square quartz cells are also available for specific optical path requirements. Their primary advantage is high purity and excellent optical transparency.

Understanding the Trade-offs

Choosing a volume involves balancing practical needs and experimental integrity. There is no single "best" volume, only the most appropriate one for your specific test.

Small Volume Cells (< 30ml)

Advantages: Requires less electrolyte, saving costs. Can reach thermal equilibrium more quickly. Disadvantages: Reactants can be depleted or products can accumulate to high concentrations, altering the test conditions. More susceptible to changes from evaporation, especially in an open cell.

Large Volume Cells (> 80ml)

Advantages: Provides a highly stable bulk electrolyte for long-term tests. Minimizes the impact of reactant depletion or product buildup. Disadvantages: Requires a large amount of electrolyte. Takes longer to heat or cool to a target temperature. May require a larger coated sample to maintain a proper surface-area-to-volume ratio.

Sealing and Customization

The need for a sealed system is often more critical than the exact volume. If your coating's performance is affected by air, a sealed cell is non-negotiable.

Remember that most manufacturers offer custom fabrication. If a standard size does not fit your sample geometry or experimental setup, a custom solution is a common and practical option.

Selecting the Right Cell for Your Coating Evaluation

Base your decision on the primary objective of your electrochemical measurement.

- If your primary focus is rapid screening or using precious materials: A smaller sealed cell (10-30ml) is efficient and cost-effective.

- If your primary focus is long-term corrosion or immersion testing: A larger volume cell (50-100ml or more) will ensure your electrolyte remains stable over the duration of the test.

- If your primary focus is studying photo-electrochemical properties: A quartz cell with an appropriate volume (e.g., 30-100ml) is necessary for optical access.

- If your primary focus is on an air-sensitive system: Prioritize a super-sealed cell design to maintain an inert atmosphere, then select the volume based on the test duration.

Ultimately, choosing the right cell is about matching its characteristics to the specific questions your experiment is designed to answer.

Summary Table:

| Cell Type | Typical Volume Range | Key Characteristics |

|---|---|---|

| Standard Glass Cell | 8ml - 80ml | Common workhorse for general electrochemistry. |

| Super-Sealed Glass Cell | 10ml - 100ml | Airtight for oxygen-sensitive or inert atmosphere tests. |

| Quartz Cell | 30ml - 100ml | Optically transparent for spectroelectrochemical studies. |

| Custom Cells | Variable | Tailored for specific sample geometries or experimental needs. |

Ready to select the perfect electrolytic cell for your coating evaluation project?

KINTEK specializes in high-quality lab equipment and consumables, including a wide range of standard and custom electrolytic cells. We understand that the right cell is critical for accurate electrochemical measurements, whether you're conducting rapid screening, long-term corrosion studies, or spectroelectrochemistry.

Our experts can help you choose the ideal cell volume and type (glass, super-sealed, or quartz) to match your experimental goals, ensuring precise results and efficient use of materials.

Contact our team today to discuss your specific needs and ensure your lab is equipped for success.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Electrolytic Electrochemical Cell with Five-Port

- Flat Corrosion Electrolytic Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What are the advantages of a flat electrochemical cell for corrosion? Achieve Precise Pitting & Crevice Analysis

- What is the difference between electrolytic corrosion cell and electrochemical corrosion cell? Understand the Driving Force Behind Corrosion

- What type of electrode system is the coating evaluation electrolytic cell designed for? Unlock Precise Coating Analysis

- How is a high-precision electrolytic cell used to evaluate metal corrosion resistance? Validate DCT Results Accurately

- What is the operating principle of a flat plate corrosion electrolytic cell? A Guide to Controlled Materials Testing