In short, fluidized bed reactors are workhorses of the chemical, petroleum, and energy industries. They are primarily used for large-scale processes involving solid particles, such as cracking heavy crude oil into gasoline, converting biomass and coal into fuel, and producing a wide range of chemicals where a solid catalyst is required. Their value comes from the ability to make a bed of solid particles behave like a fluid, enabling superior heat transfer and mixing.

The decision to use a fluidized bed reactor is not about the specific industry, but about the physics of the process. They are the ideal choice when a reaction requires uniform temperature, excellent contact between gases and solids, and the continuous handling of solid particles.

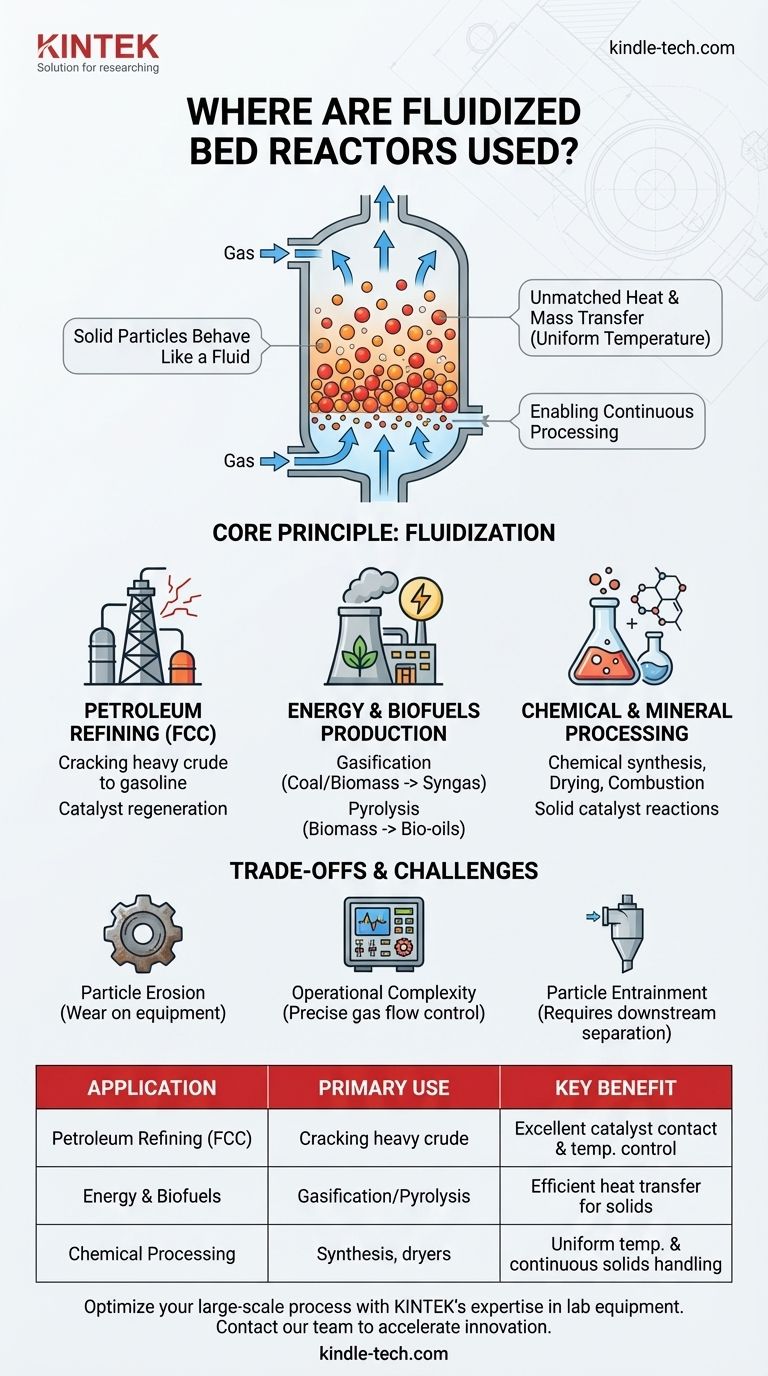

The Core Principle: Why Fluidization Matters

At its heart, a fluidized bed reactor solves the fundamental challenge of efficiently managing reactions between a gas and a solid. Instead of a static pile of material, the solid particles are energized into a dynamic, fluid-like state.

Achieving Liquid-Like Behavior

A fluidized bed is created by pushing a gas upward through a bed of fine solid particles. As the gas velocity increases, it begins to support the weight of the particles, causing them to separate and move around freely. The result is a bubbling, churning mass that behaves much like a boiling liquid.

Unmatched Heat and Mass Transfer

This "boiling" motion is the reactor's key advantage. The constant, vigorous mixing ensures an almost perfectly uniform temperature throughout the entire bed, eliminating dangerous hot spots that could ruin a product or damage a catalyst. It also guarantees intimate contact between the gas and the surface of every solid particle, dramatically increasing reaction speed and efficiency.

Enabling Continuous Processing

Because the solid bed behaves like a fluid, it can be handled continuously. Fresh solid material (like feedstock or catalyst) can be fed into one side of the reactor, and spent material can be drained from the other. This is essential for the massive throughput required in processes like petroleum refining.

Key Applications Across Industries

The unique properties of fluidized beds make them indispensable for several high-value industrial processes.

Petroleum Refining (Fluid Catalytic Cracking)

The most common application is Fluid Catalytic Cracking (FCC). In an FCC unit, heavy, low-value fractions of crude oil are vaporized and fed into a fluidized bed of a very fine powder catalyst. The intense mixing and uniform high temperature efficiently "crack" the large hydrocarbon molecules into smaller, more valuable ones like gasoline. The catalyst is continuously cycled to a second vessel to be regenerated by burning off coke deposits.

Energy and Biofuels Production

Fluidized beds are central to modern energy conversion technologies, especially for solid fuels.

- Gasification: Coal or biomass is fed into a fluidized bed where it reacts with a controlled amount of oxygen and/or steam. This produces a combustible "syngas" which can be burned to generate electricity or used as a chemical feedstock.

- Pyrolysis: Biomass, plastics, or other organic materials are rapidly heated in the absence of oxygen. The fluidized bed's excellent heat transfer maximizes the yield of valuable liquid "bio-oils" and gases. This is particularly effective for particulate feedstocks like wood chips.

Chemical and Mineral Processing

Fluidized bed reactors are used in a wide array of chemical synthesis and processing operations. This includes combustors, dryers, and reactors for producing chemicals like phthalic anhydride and acrylonitrile. In all cases, they are chosen when a solid catalyst or reactant needs to be maintained at a uniform temperature while being thoroughly mixed with a process gas.

Understanding the Trade-offs

While powerful, fluidized bed reactors are not a universal solution. Their dynamic nature introduces specific engineering challenges that must be managed.

Particle Erosion

The constant motion and high velocity of the solid particles can cause significant wear and tear on the reactor's internal walls, piping, and control instruments. Materials of construction must be carefully selected to withstand this erosion over long periods of operation.

Complexity of Operation

Maintaining a stable fluidized state requires precise control over gas flow rates. If the flow is too low, the bed will slump; if it is too high, too many particles will be blown out of the reactor. This operational complexity is greater than that of simpler designs like fixed-bed reactors.

Particle Entrainment

The gas leaving the reactor will inevitably carry some of the finer solid particles with it. This requires the installation of downstream separation systems, most commonly cyclones, to capture these particles and return them to the reactor or collect them as product.

Is a Fluidized Bed Reactor Right for Your Process?

Choosing the right reactor technology depends entirely on your process requirements and priorities.

- If your primary focus is processing large volumes of solid particles continuously: A fluidized bed reactor is likely the superior choice due to its excellent solids handling capabilities.

- If your primary focus is a reaction requiring precise temperature control: The uniform temperature profile of a fluidized bed prevents hot spots, making it ideal for sensitive catalytic or exothermic reactions.

- If your process involves simple, fixed solids and lower throughput: A simpler fixed-bed or packed-bed reactor might be a more cost-effective and less complex solution.

Ultimately, selecting a fluidized bed reactor is a strategic decision driven by the need for superior mixing and thermal management in complex solid-gas systems.

Summary Table:

| Application | Primary Use | Key Benefit |

|---|---|---|

| Petroleum Refining (FCC) | Cracking heavy crude oil into gasoline | Excellent catalyst contact & temperature control |

| Energy & Biofuels | Gasification of coal/biomass; pyrolysis | Efficient heat transfer for solid fuel conversion |

| Chemical Processing | Synthesis of chemicals (e.g., phthalic anhydride) | Uniform temperature & continuous solids handling |

Optimize your large-scale chemical or energy process with KINTEK's expertise in lab equipment and consumables. Whether you're developing catalysts for fluidized bed reactors or scaling up a new gasification process, our specialized solutions support your R&D and production needs. Contact our team today to discuss how we can enhance your laboratory's efficiency and accelerate your innovation.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What technical requirements must high-temperature industrial kilns meet for the chlorination roasting of quartz sand?

- What are the advantages of microwave-assisted pyrolysis? Achieve Faster, More Efficient Bio-Oil Production

- What is the purpose of a fluidized bed? Achieve Superior Heat Transfer and Process Efficiency

- What is the maximum temperature of a rotary kiln? From 200°C to 2500°C for Your Process

- Do electric kilns use a lot of electricity? Understanding Kiln Power Consumption and Costs

- What are the different types of pyrolysis oil? Choosing the Right Process for Your Fuel or Chemical Needs

- What are the advantages of catalytic pyrolysis over thermal pyrolysis? Achieve Higher-Quality Bio-Oil and Chemicals

- What type of process is calcination? A Guide to Precise Thermal Decomposition