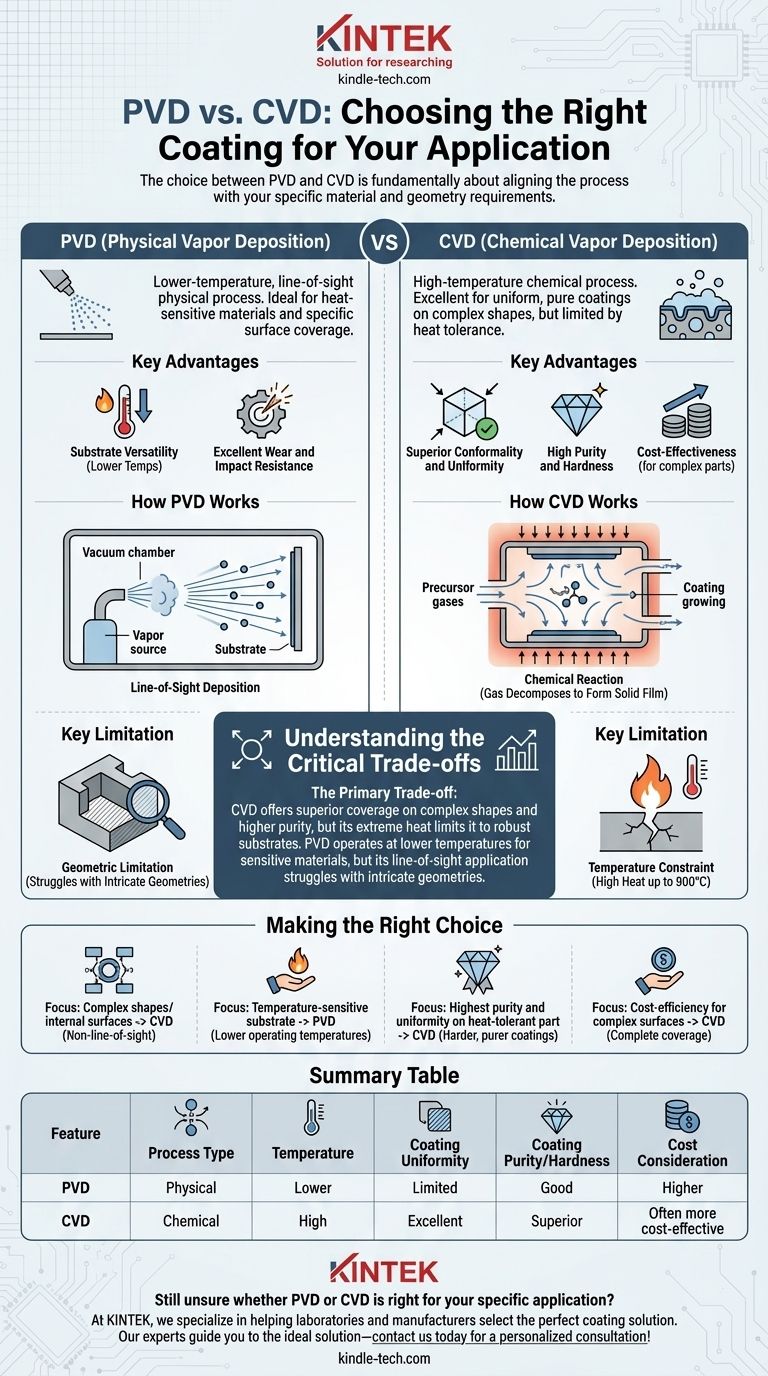

The choice between PVD and CVD is not about which is "better" overall, but which is fundamentally suited to your specific material and geometry. Physical Vapor Deposition (PVD) is a lower-temperature, line-of-sight process ideal for coating heat-sensitive materials or when only specific surfaces need coverage. In contrast, Chemical Vapor Deposition (CVD) is a high-temperature chemical process that excels at creating highly uniform, pure coatings on complex shapes but is limited to substrates that can withstand its extreme heat.

The decision hinges on a primary trade-off: CVD offers superior coverage on complex shapes and higher purity, but its extreme heat limits it to robust substrates. PVD operates at lower temperatures, making it versatile for sensitive materials, but its line-of-sight application struggles with intricate geometries.

The Fundamental Difference: How the Coating is Applied

The core distinction between these two technologies lies in their deposition method. This single difference is the source of nearly all their respective advantages and disadvantages.

How PVD Works (Line-of-Sight Deposition)

PVD is a physical process. A solid coating material is vaporized in a vacuum, and its atoms travel in a straight line to condense onto the substrate.

Think of it like spray painting. The coating only lands on the surfaces that are directly in the "line of sight" of the vapor source.

How CVD Works (Chemical Reaction)

CVD is a chemical process. The substrate is placed in a chamber and heated to a high temperature, while volatile precursor gases are introduced.

These gases react on the hot surface of the substrate, decomposing to form a solid film. This process "grows" the coating on every exposed surface, regardless of orientation.

Key Advantages of CVD

CVD's chemical nature gives it distinct advantages in applications where uniformity and purity are paramount.

Superior Conformality and Uniformity

Because the coating is formed by a gas that envelops the entire part, CVD creates a perfectly uniform film even in deep holes, on internal walls, and over complex shapes. This is something PVD cannot achieve.

High Purity and Hardness

The chemical reaction process results in coatings that are exceptionally high-purity, fine-grained, and often harder than materials produced by other methods.

Cost-Effectiveness

In many scenarios, CVD is a cheaper process than PVD. It can be performed at atmospheric pressure and provides excellent coating properties across all surfaces without complex loading and fixing procedures.

Key Advantages of PVD

PVD's primary advantage stems from its lower operating temperature, making it compatible with a much wider range of materials.

Substrate Versatility (Lower Temperatures)

The most significant benefit of PVD is its suitability for temperature-sensitive materials. CVD processes can reach 900°C, which would destroy or damage many substrates. PVD provides a high-performance coating solution for these materials.

Excellent Wear and Impact Resistance

PVD coatings are known for their high temperature resistance, abrasion resistance, and impact resistance. This makes them common in demanding industries like automotive and construction.

Understanding the Critical Trade-offs

Neither technology is a universal solution. Your choice requires a clear understanding of their inherent limitations.

The Temperature Constraint of CVD

The extreme heat required for the CVD process is its greatest weakness. If your substrate cannot withstand temperatures approaching 900°C, CVD is not a viable option.

The Geometric Limitation of PVD

The line-of-sight nature of PVD is its biggest drawback. It cannot effectively coat complex internal geometries or deeply recessed areas, leading to uneven or non-existent coverage in shaded spots.

The Cost Factor

While CVD is often cheaper, the cost of PVD is driven by its complex loading and fixing processes needed to orient parts correctly for line-of-sight coating. This can make it more expensive, particularly for high-volume production.

Making the Right Choice for Your Application

Your decision should be guided by your primary technical and budget constraints.

- If your primary focus is coating complex shapes or internal surfaces: CVD is the superior option due to its non-line-of-sight chemical deposition.

- If your primary focus is coating a temperature-sensitive substrate: PVD is the necessary choice because its lower operating temperatures will not damage the part.

- If your primary focus is achieving the highest purity and uniformity on a heat-tolerant part: CVD generally provides harder, purer, and more uniform coatings.

- If your primary focus is cost-efficiency for parts with complex surfaces: CVD is often the more cost-effective solution for providing complete coverage on all tool surfaces.

By prioritizing your substrate's thermal limitations and the geometry of your part, you can confidently select the coating technology that delivers the required performance.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (line-of-sight) | Chemical (non-line-of-sight) |

| Temperature | Lower (suitable for heat-sensitive materials) | High (up to 900°C, requires robust substrates) |

| Coating Uniformity | Limited on complex geometries | Excellent on complex shapes and internal surfaces |

| Coating Purity/Hardness | Good wear/impact resistance | Superior purity and hardness |

| Cost Consideration | Higher due to complex part loading | Often more cost-effective for complex parts |

Still unsure whether PVD or CVD is right for your specific application?

At KINTEK, we specialize in helping laboratories and manufacturers select the perfect coating solution. Our expertise in lab equipment and consumables ensures you get optimal performance for your substrates and geometries.

Let our experts guide you to the ideal solution—contact us today for a personalized consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films