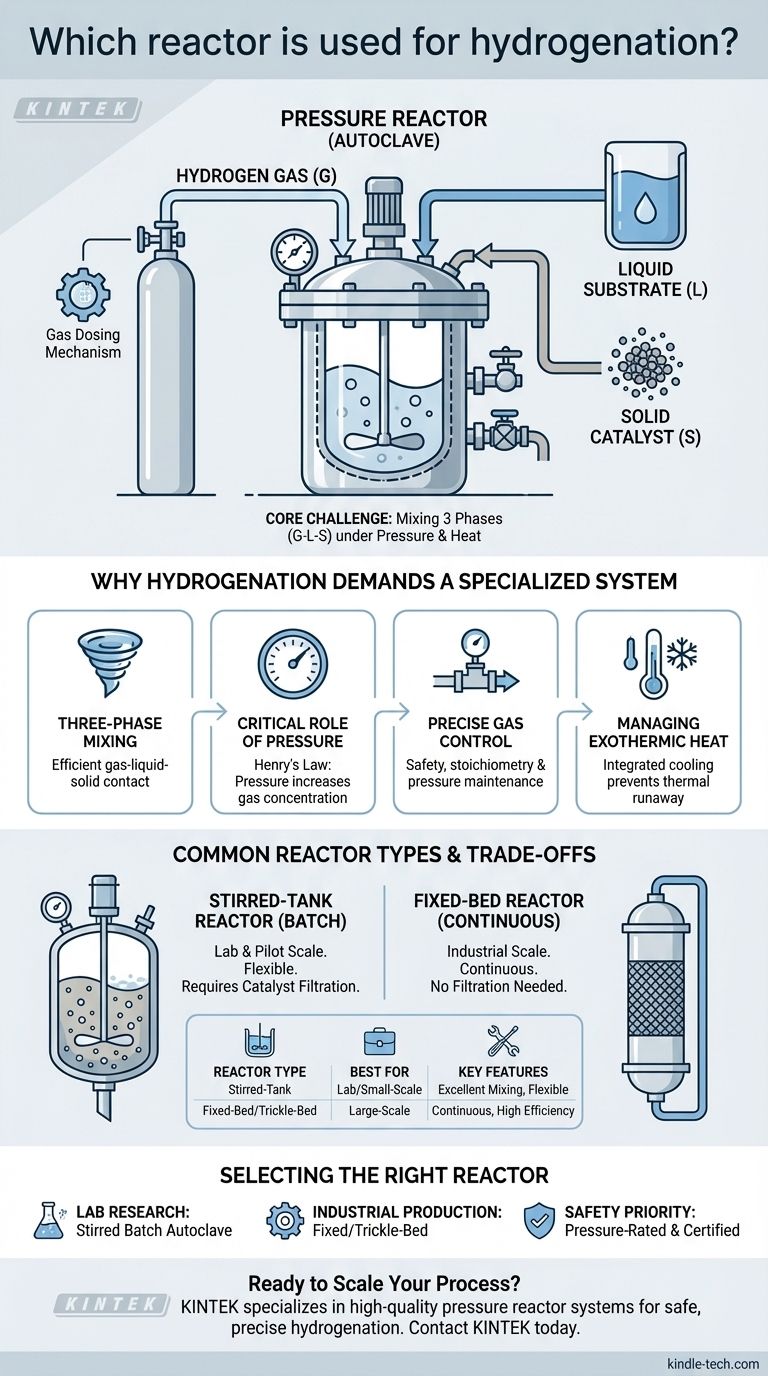

For hydrogenation reactions, the most common and effective piece of equipment is a pressure reactor, often referred to as an autoclave or hydrogenator. This reactor is almost always part of a system that includes a precise gas dosing mechanism to safely control the flow of hydrogen gas. This combination is the standard for creating a safe, controlled, and reproducible environment for the reaction.

The core challenge of hydrogenation is not just containing the reaction, but effectively mixing three different phases—a gas (hydrogen), a liquid (the substrate), and a solid (the catalyst)—under pressure. Therefore, the "right reactor" is actually a complete system designed to manage this complex interaction safely and efficiently.

Why Hydrogenation Demands a Specialized System

Hydrogenation isn't like a simple liquid-phase reaction conducted in a glass flask. The nature of the reactants and the reaction conditions necessitate specialized equipment designed to handle pressure, manage heat, and ensure safety.

The Challenge of Three-Phase Mixing

Most hydrogenations are heterogeneous reactions involving three phases. You must efficiently dissolve gaseous hydrogen into a liquid substrate so it can interact with the surface of a solid catalyst.

The reactor's primary job is to facilitate this contact. Inadequate mixing leads to a slow or incomplete reaction, as the rate is often limited by how fast the hydrogen can get to the catalyst surface.

The Critical Role of Pressure

Hydrogen has very low solubility in most organic solvents at atmospheric pressure. Applying pressure is the single most important factor for increasing its concentration in the liquid phase.

According to Henry's Law, the amount of dissolved gas is directly proportional to the partial pressure of that gas above the liquid. Doubling the pressure effectively doubles the available hydrogen for the reaction, dramatically increasing the reaction rate.

The Need for Precise Gas Control

A gas dosing system is critical for both safety and accuracy. It allows you to add hydrogen in a controlled manner, preventing the accidental formation of an explosive hydrogen-air mixture.

It also ensures you add the correct stoichiometric amount of hydrogen, preventing over-reduction or waste of gas. This system works in tandem with pressure sensors to maintain the desired reaction pressure.

Managing a Highly Exothermic Reaction

Many hydrogenation reactions are highly exothermic, releasing a significant amount of heat. If this heat is not removed, the temperature and pressure can rise uncontrollably, creating a dangerous situation known as thermal runaway.

Pressure reactors are therefore built with integrated cooling systems, such as an internal cooling loop or an external jacket, to maintain a stable temperature.

Common Reactor Types for Hydrogenation

While the term "pressure reactor" is a general category, the specific design depends on the scale and nature (batch or continuous) of the process.

Stirred-Tank Reactors (Slurry Reactors)

This is the most common design for laboratory-scale and pilot-plant batch processes. The reactor is a sealed vessel (autoclave) equipped with a mechanical stirrer.

In this setup, the solid catalyst is suspended in the liquid substrate as a fine powder, creating a "slurry." The stirrer's job is twofold: to agitate the liquid to create a vortex that draws hydrogen gas from the headspace into the liquid, and to keep the catalyst particles suspended and evenly distributed.

Fixed-Bed Reactors

For large-scale, continuous industrial production, fixed-bed reactors are the standard. In this design, the catalyst particles are packed into a stationary "bed" within a column.

The liquid reactant and hydrogen gas are then passed through this bed together. This design eliminates the need for post-reaction catalyst filtration, a major advantage for continuous operations.

Trickle-Bed Reactors

A trickle-bed reactor is a specific type of fixed-bed reactor. Here, the liquid reactant trickles down through the catalyst bed via gravity, while the hydrogen gas flows either concurrently (downward) or counter-currently (upward). This design is highly efficient for mass transfer in many large-scale industrial hydrogenations.

Understanding the Trade-offs and Safety

Choosing a reactor involves balancing efficiency, scale, and significant safety considerations.

Batch vs. Continuous Processing

Stirred-tank reactors are ideal for batch production. They offer high flexibility for running different reactions and volumes but require downtime between batches for cleaning and catalyst filtration.

Fixed-bed reactors are built for continuous, high-throughput production of a single product. They have higher upfront costs but offer lower operational costs and greater efficiency at scale.

Catalyst Handling and Separation

In a slurry reactor, separating the fine catalyst powder from the product liquid after the reaction can be a significant challenge, often requiring specialized filtration. In a fixed-bed reactor, the catalyst stays in place, and the product flows out cleanly, simplifying the process immensely.

Critical Safety: Handling Hydrogen

Hydrogen is extremely flammable and can form explosive mixtures with air over a very wide concentration range (4-75%). Therefore, the single most important factor is safety.

Any hydrogenation reactor must be made from materials that resist hydrogen embrittlement and be certified to withstand pressures far exceeding the intended operating pressure. It must also include safety features like a rupture disc or relief valve to prevent catastrophic failure.

Selecting the Right Reactor for Your Goal

Your choice of reactor is dictated by your operational scale and ultimate objective.

- If your primary focus is laboratory research or small-scale synthesis: A stirred, batch pressure reactor (autoclave) with an integrated gas dosing system and temperature control is the industry standard.

- If your primary focus is large-scale, continuous industrial production: A fixed-bed or trickle-bed reactor is the most efficient and economical solution for high-volume manufacturing.

- If safety is your absolute top priority (as it should be): Ensure any selected reactor is pressure-rated, constructed from certified materials, and equipped with robust safety features like pressure relief and thermal management.

Ultimately, a successful hydrogenation depends on a complete system designed to master pressure, temperature, and three-phase mixing in a controlled and safe environment.

Summary Table:

| Reactor Type | Best For | Key Features |

|---|---|---|

| Stirred-Tank (Batch) | Lab R&D, Small-Scale Synthesis | Excellent mixing, flexible for different reactions, requires catalyst filtration |

| Fixed-Bed / Trickle-Bed (Continuous) | Large-Scale Industrial Production | Continuous operation, no catalyst filtration, high efficiency at scale |

Ready to Scale Your Hydrogenation Process Safely and Efficiently?

Choosing the right reactor is critical for the success and safety of your hydrogenation reactions. KINTEK specializes in high-quality lab equipment, including robust pressure reactor systems designed for precise gas dosing, temperature control, and safe three-phase mixing.

Whether you are conducting research in a laboratory or scaling up for production, our solutions are engineered to meet your needs. Let our experts help you select the perfect system to enhance your workflow and ensure reproducible results.

Contact KINTEK today to discuss your hydrogenation requirements and discover how our equipment can drive your projects forward.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What conditions does a hydrothermal reactor provide for CuO nanofilms? Master High-Pressure Synthesis

- What is the primary role of high-pressure reactors in the hot water extraction (HWE) process? Unlock Green Biorefining

- What is reactor in pharmaceutical industry? The Heart of Precise Drug Synthesis

- What is the importance of using corrosion-resistant materials in subcritical water treatment? Protect Purity & Longevity

- Why are high-pressure corrosion-resistant reactors required for the dilute acid pretreatment of perennial grasses?

- What is the purpose of using anaerobic batch reactors in food wastewater? Optimize Methane Yield and BMP Testing

- How does a high-temperature reactor influence CVD coating quality? Unlock Superior Density and Adhesion

- What is the function of a high-pressure batch reactor? Expert Insights on Hydrogenating LA to GVL