The high cost of a manufacturing mold is a direct reflection of what it is: a custom-built, high-precision piece of industrial machinery. Its price isn't for a simple metal block, but for the immense amount of skilled labor, advanced machining time, and high-grade materials required to create a tool capable of producing thousands or millions of identical parts with extreme accuracy and speed.

A mold's price tag can be shocking until you reframe your perspective. You are not buying a part; you are commissioning a durable, custom-engineered machine whose sole purpose is to replicate your design perfectly and efficiently at scale. The cost is an investment in manufacturing capability, not a simple expense.

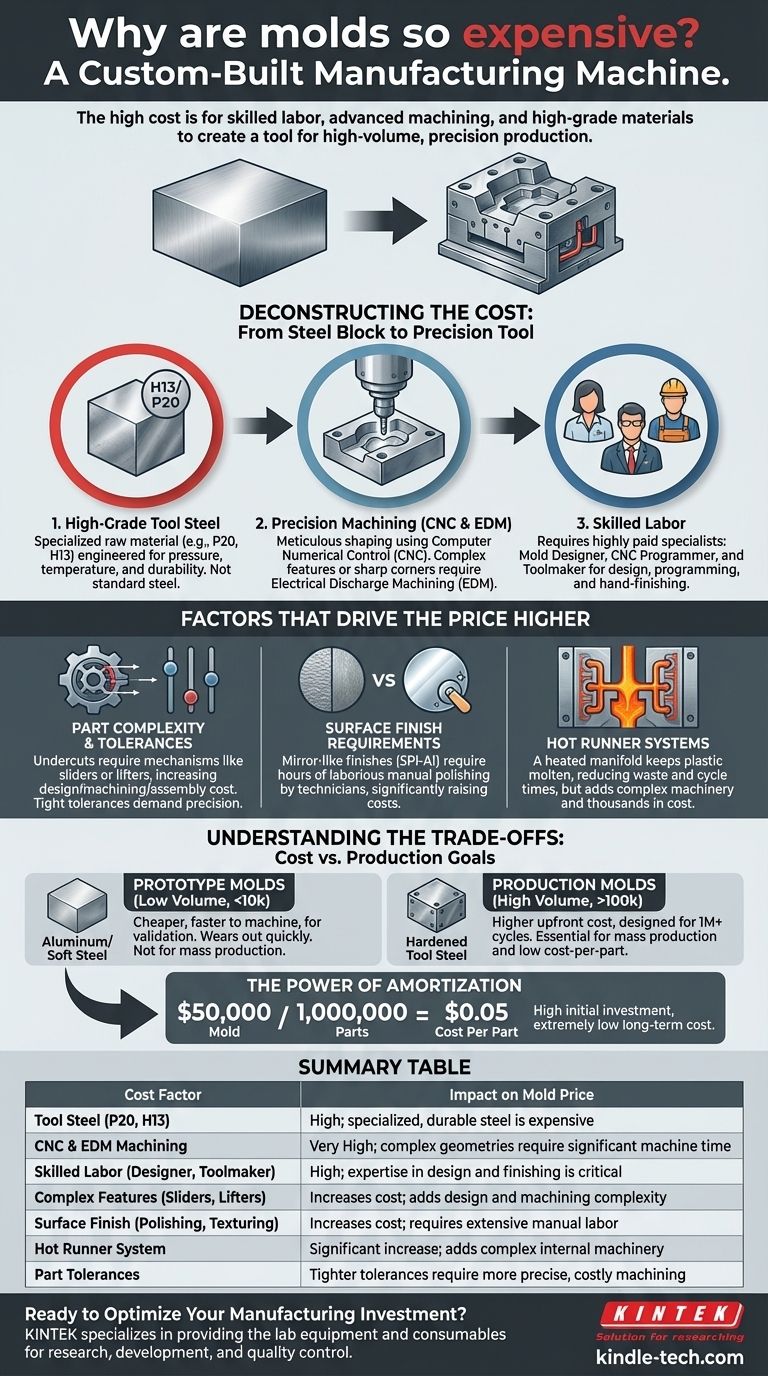

Deconstructing the Cost: From Steel Block to Precision Tool

A mold begins as a block of specialized steel and is transformed through a series of expensive, time-consuming processes. Each step adds significant cost but is essential for creating a reliable production tool.

The Foundation: High-Grade Tool Steel

The raw material itself is a major cost factor. Molds are not made from standard, low-cost steel. They are built from high-grade tool steel, such as P20 or H13.

This specialized steel is engineered to withstand the immense pressure and high temperatures of the injection molding process over hundreds of thousands of cycles without deforming or wearing out. Hardened tool steels like H13, used for multi-million part runs, are even more expensive and significantly harder to machine, further increasing costs.

The Core Process: Precision Machining

This is the single largest cost driver. The steel block is meticulously shaped using CNC (Computer Numerical Control) machining. A computer-guided cutter carves out the cavity—the negative space of your part—from the solid block.

The more complex your part's geometry, the more machining time is required. Features like fine details, deep ribs, or curved surfaces demand longer, more complex machining paths. For sharp internal corners or features that a milling tool cannot physically reach, an even more specialized process called EDM (Electrical Discharge Machining) is used, which is slower and adds further cost.

The Human Element: Skilled Labor and Design

Creating a mold requires a team of highly paid specialists. It starts with a mold designer, an engineer who translates your part design into a functional mold, planning for things like material flow, cooling channels, and part ejection.

Then, a CNC programmer creates the complex toolpaths for the machine, and a skilled toolmaker oversees the entire process, from machine setup to final assembly and hand-finishing. The hours of these experts' time are a substantial portion of the final bill.

Factors That Drive the Price Higher

Beyond the basic manufacturing process, specific features of your part design can dramatically increase the complexity and cost of the mold.

Part Complexity and Tolerances

If your part has undercuts—features that prevent it from being pulled directly out of the mold—the mold must include complex mechanisms. These can be sliders (side-actions) or lifters that move into place before injection and then retract to allow the part to be ejected. These add significant design, machining, and assembly costs.

Likewise, demanding tight tolerances means the mold must be machined with extreme precision, requiring more careful setups, slower machining speeds, and more rigorous quality checks, all of which increase the cost.

Surface Finish Requirements

The finish on your plastic part is a direct copy of the finish inside the mold cavity. A standard, as-machined finish is the cheapest option.

However, if you require a textured or highly polished, mirror-like finish (an SPI-A1 standard), the cost rises dramatically. This level of finish is achieved through hours of laborious, manual hand-polishing by a highly skilled technician.

Hot Runner Systems

A mold needs a way for molten plastic to get into the cavity. A basic cold runner system is a simple channel that freezes with the part and is ejected as waste.

A hot runner system is a heated manifold that keeps the plastic molten all the way to the part. This eliminates waste and can reduce cycle times, but it is effectively a complex piece of machinery built inside your mold, adding thousands or tens of thousands of dollars to the upfront cost.

Understanding the Trade-offs: Cost vs. Production Goals

The most common mistake is trying to cut corners on mold quality to save on the initial investment. This approach almost always leads to higher costs and production problems down the line.

The Myth of the "Cheap" Mold

A poorly made, "cheap" mold is a liability. It may suffer from premature wear, produce parts with defects like flash or sink marks, and require frequent downtime for maintenance. The cost of lost production time and flawed parts quickly outweighs any initial savings.

Prototype Molds vs. Production Molds

For low-volume runs (typically under 10,000 units), you can use a mold made from softer steel or even high-grade aluminum. These materials are cheaper and faster to machine, resulting in a much lower upfront cost. However, they will wear out quickly and are not suitable for mass production.

A production mold made from hardened tool steel (like H13) costs significantly more but is designed to last for 1,000,000+ cycles. The choice depends entirely on your production forecast.

The Power of Amortization

The high upfront cost of a production mold becomes negligible when spread across a high volume of parts. A $50,000 mold that produces one million parts only adds $0.05 to the cost of each individual part. This is the fundamental economic principle of injection molding: high initial investment for an extremely low cost-per-part.

Making the Right Choice for Your Project

The right mold strategy depends entirely on your production goals. Investing appropriately upfront is critical for success.

- If your primary focus is rapid prototyping or low-volume validation (<10,000 units): Consider a softer steel or an aluminum mold to minimize your initial investment while you validate your design.

- If your primary focus is mass production and the lowest cost-per-part (>100,000 units): Invest in a high-quality, multi-cavity, hardened steel mold, potentially with a hot runner system, to maximize efficiency and longevity.

- If your primary focus is balancing cost for medium volumes (10,000-100,000 units): A single-cavity mold made from P20 tool steel is the industry workhorse, providing a reliable and cost-effective solution for most applications.

Understanding that a mold is a long-term manufacturing asset, not a one-time expense, is the key to making a sound investment in your product's future.

Summary Table:

| Cost Factor | Impact on Mold Price |

|---|---|

| Tool Steel (P20, H13) | High; specialized, durable steel is expensive |

| CNC & EDM Machining | Very High; complex geometries require significant machine time |

| Skilled Labor (Designer, Toolmaker) | High; expertise in design and finishing is critical |

| Complex Features (Sliders, Lifters) | Increases cost; adds design and machining complexity |

| Surface Finish (Polishing, Texturing) | Increases cost; requires extensive manual labor |

| Hot Runner System | Significant increase; adds complex internal machinery |

| Part Tolerances | Tighter tolerances require more precise, costly machining |

Ready to Optimize Your Manufacturing Investment?

Navigating mold costs and specifications is complex. KINTEK specializes in providing the lab equipment and consumables necessary for research, development, and quality control in manufacturing processes. Whether you are prototyping or scaling up production, having the right tools is crucial for success.

Let us help you equip your lab for efficiency and precision. Contact our experts today to discuss how KINTEK's solutions can support your project from concept to final product.

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Copper Foam

- Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

People Also Ask

- What is the role of a stainless steel mold in solid-state battery testing? Ensure Stability and High-Pressure Contact

- How are samples typically prepared and measured using the diffuse reflection method? Optimize Your Lab's IR Spectroscopy

- What are the primary functions of PEEK test molds? Essential Tools for All-Solid-State Battery Assembly

- Why is the KBr plate used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How much does a production mold cost? A Strategic Guide to Injection Mold Pricing

- What are the specific roles of graphite molds in the hot press sintering process of TiC10/Cu-Al2O3 composites?

- What is the function of a BN inner liner in a graphite mold during Flash Sintering? Master Precise Current Control

- How do graphite molds and hydraulic presses work together? Perfect Your FeCrAl Pre-Forming Today!