Proper use of laboratory apparatus is the bedrock of sound science. It is a non-negotiable requirement for ensuring the physical safety of all personnel, guaranteeing the accuracy and reproducibility of experimental data, and preserving the integrity and lifespan of expensive, sensitive equipment. Failing to adhere to correct procedures introduces unacceptable risks and fundamentally invalidates the work being performed.

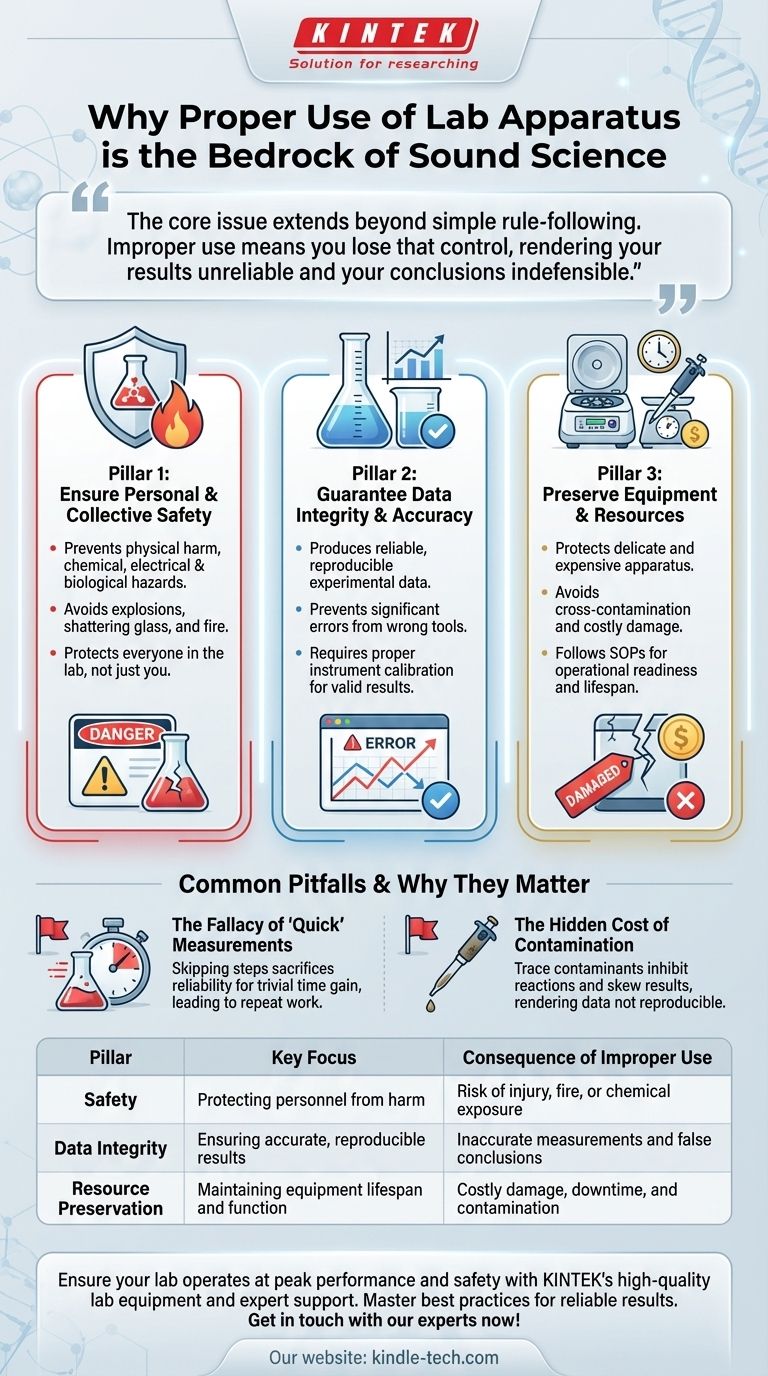

The core issue extends beyond simple rule-following. Each piece of laboratory equipment is designed to precisely control a variable—be it volume, mass, temperature, or time. Improper use means you lose that control, rendering your results unreliable and your conclusions indefensible.

The Three Pillars of Proper Lab Practice

Understanding why we use equipment a certain way can be broken down into three fundamental principles. These pillars are interconnected and form the foundation of a safe, effective, and professional laboratory environment.

Pillar 1: Ensuring Personal and Collective Safety

The most immediate consequence of improper equipment use is physical harm. A laboratory contains chemical, biological, electrical, and physical hazards that are managed through correct handling procedures.

For example, heating a closed container can cause it to explode. Using glassware with hairline cracks can cause it to shatter under thermal stress or vacuum pressure. Mishandling electrical equipment like power supplies can lead to shock or fire.

Your actions do not exist in a vacuum. A mistake, such as leaving a Bunsen burner unattended or spilling a volatile chemical, endangers not just you but everyone else in the lab.

Pillar 2: Guaranteeing Data Integrity and Accuracy

The goal of scientific experimentation is to produce reliable, reproducible data. The quality of your data is entirely dependent on the precision of your measurements.

Using the wrong tool for the job, such as measuring 10.0 mL of a solution with a beaker instead of a volumetric pipette, introduces significant error. This error cascades through every subsequent calculation, potentially leading to completely false conclusions.

Similarly, failing to properly calibrate an instrument, like a pH meter or an analytical balance, means every single measurement taken is inaccurate. This invalidates the entire experiment and represents a total waste of time and resources.

Pillar 3: Preserving Equipment and Resources

Laboratory apparatus is often delicate and expensive. Correct usage is a matter of financial stewardship and operational readiness.

Improper cleaning can lead to cross-contamination that ruins future experiments, or it can etch and damage delicate glassware. Operating a centrifuge with an unbalanced load can destroy the motor, resulting in thousands of dollars in replacement costs and significant downtime.

Following the manufacturer's instructions and standard operating procedures (SOPs) for startup, operation, and shutdown ensures the equipment functions correctly for its intended lifespan.

Common Pitfalls and Why They Matter

In any professional environment, there is a temptation to find shortcuts. In a laboratory, these shortcuts almost always lead to negative consequences.

The Fallacy of the "Quick" Measurement

Skipping a step, like waiting for a balance to stabilize or not allowing a volumetric solution to reach room temperature, may save a few seconds. However, the inaccurate data it produces can force you to repeat an entire day's worth of work.

The most efficient path is always the correct one. Rushing a measurement is a false economy that sacrifices reliability for a trivial gain in time.

The Hidden Cost of Contamination

Using a non-sterile pipette tip for a second sample or failing to properly rinse a container between reagents introduces contamination. This is one of the most insidious forms of error.

It may not be immediately obvious, but a trace contaminant can inhibit a reaction, produce a false positive, or skew a reading. This leads to results that are not reproducible and can send a research project in the wrong direction for weeks or months.

Making the Right Choice for Your Goal

Adopting the right mindset is crucial for translating these principles into daily practice. Before you begin any task, consider your primary objective.

- If your primary focus is safety: Always perform a mental risk assessment before using any equipment, asking "What could go wrong here and how do I prevent it?"

- If your primary focus is accuracy: Treat every measurement as a critical data point and always use the designated, calibrated instrument for the task.

- If your primary focus is efficiency: Recognize that following the standard operating procedure correctly the first time is the fastest path to a valid and trustworthy result.

Ultimately, mastering your tools is the absolute foundation of reliable and impactful scientific work.

Summary Table:

| Pillar | Key Focus | Consequence of Improper Use |

|---|---|---|

| Safety | Protecting personnel from harm | Risk of injury, fire, or chemical exposure |

| Data Integrity | Ensuring accurate, reproducible results | Inaccurate measurements and false conclusions |

| Resource Preservation | Maintaining equipment lifespan and function | Costly damage, downtime, and contamination |

Ensure your lab operates at peak performance and safety. Proper equipment use is non-negotiable for reliable results. KINTEK specializes in providing high-quality lab equipment and consumables, backed by expert support to help your team master best practices.

Contact us today to discuss your laboratory needs and discover how our solutions can enhance your lab's safety, accuracy, and efficiency.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What do you use a muffle furnace for? Achieve Contamination-Free High-Temperature Processing

- What is the heating mechanism of a muffle furnace? Unlock Precise, Contamination-Free Heating

- What is the working temperature of a muffle furnace? Achieve Precise Heat Control for Your Lab

- What are the safety precautions for a muffle furnace? A Guide to Preventing Burns, Fires, and Electrical Hazards

- What are the components of a muffle furnace? Unlock the Core Systems for Precise, Safe Heating