In the precise world of milling and baking, ash content serves as a reliable chemical proxy for flour purity and its extraction rate. It directly measures the total mineral content of the flour, which is not evenly distributed throughout the wheat kernel. Because these minerals are overwhelmingly concentrated in the bran and germ, the ash value gives a remarkably accurate indication of how much of this non-starchy material is present in the final flour.

Ash content is not a measure of quality in absolute terms, but rather a precise indicator of flour composition. It tells you exactly how much of the mineral-rich bran and germ was separated from the starchy endosperm during milling, which in turn predicts the flour's color, nutritional value, and baking performance.

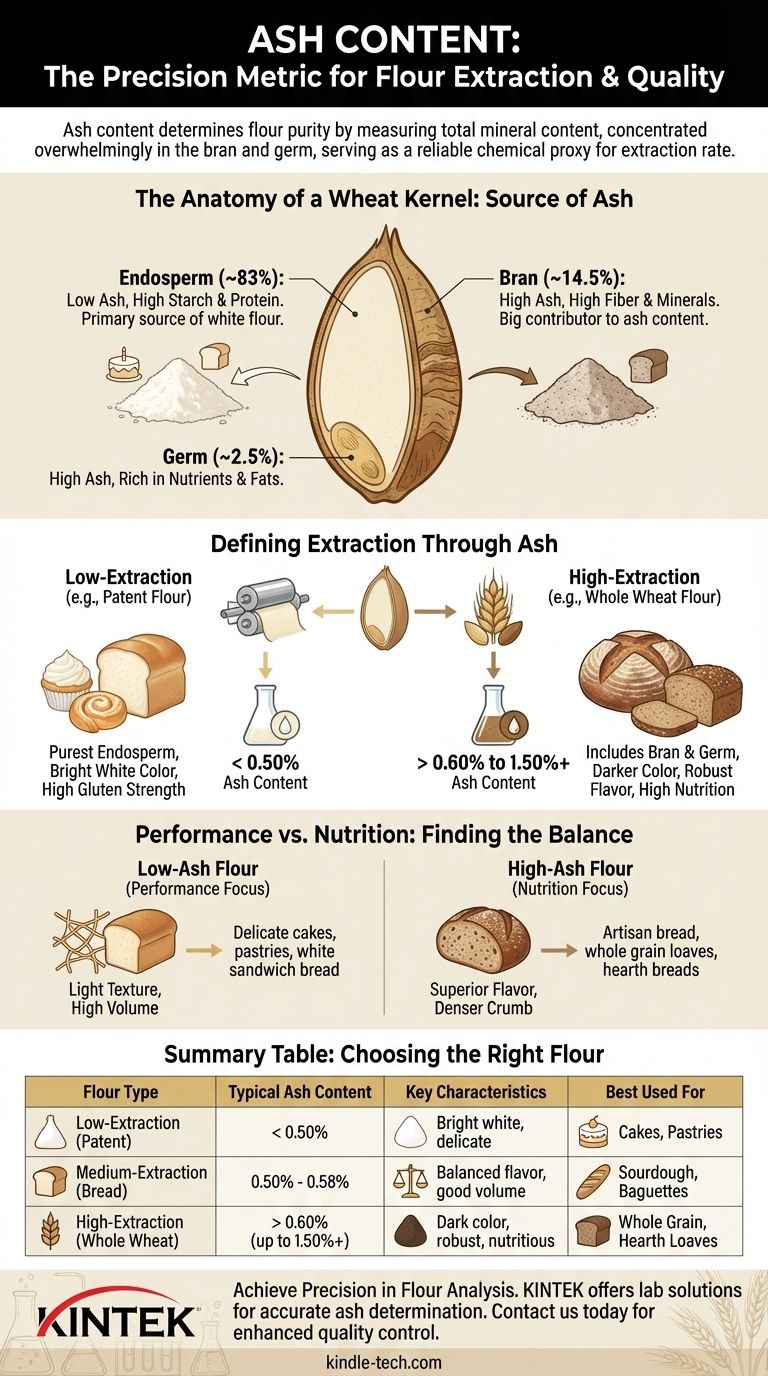

The Anatomy of a Wheat Kernel: The Source of Ash

To understand why ash is such a powerful metric, you must first understand the composition of the wheat kernel itself. The kernel consists of three primary parts, each with a vastly different mineral profile.

The Endosperm: Low Ash, High Starch

The endosperm is the largest part of the kernel (about 83%) and is the primary source of the white flour we use for baking. It is composed mainly of starch and protein (gluten).

Crucially, the endosperm is very low in minerals. A flour milled exclusively from the pure, inner endosperm will therefore have a very low ash content.

The Bran: High Ash, High Fiber

The bran is the hard, outer layer of the kernel (about 14.5%). It is rich in dietary fiber, B vitamins, and, most importantly, minerals.

Any significant amount of bran in a flour will dramatically increase its ash content. This is the single biggest contributor to ash in high-extraction and whole wheat flours.

The Germ: High Ash, Rich in Nutrients

The germ is the embryo of the wheat plant (about 2.5%). While small, it is a powerhouse of nutrients, including fats, vitamins, and minerals.

Like the bran, the germ has a high mineral concentration. Its presence in flour contributes to both a higher ash value and a shorter shelf life due to its fat content.

How Ash Content Defines Flour Extraction

The goal of milling is to separate the endosperm from the bran and germ to a specific degree. The ash test is the quality control check that validates the success of this separation.

The Milling Process: A Game of Separation

During milling, rollers break open the wheat kernel and scrape the endosperm away from the bran. A series of sieves then sorts the particles by size.

Finer particles are typically from the pure endosperm, while larger, darker particles are fragments of bran. The miller can control which streams are blended to create a flour with a specific extraction rate and, consequently, a specific ash content.

Low-Extraction vs. High-Extraction

A low-extraction flour (like a patent flour for cakes) is produced by taking only the purest, innermost part of the endosperm. This results in a very low ash content (e.g., 0.40%), a bright white color, and high protein quality.

A high-extraction flour (like a first clear or whole wheat flour) includes most or all of the kernel. This results in a high ash content (e.g., 1.50% or more), a darker color, more flavor, and higher nutritional value.

Understanding the Trade-offs: Performance vs. Nutrition

Choosing a flour based on ash content is a deliberate act of balancing competing characteristics. There is no single "best" ash content; there is only the right one for a specific goal.

The Case for Low-Ash Flour

Flours with low ash content excel at creating light textures and high volume. The minimal presence of bran particles means gluten can form long, uninterrupted, and highly elastic sheets, trapping gas efficiently. This is ideal for delicate cakes, fluffy white bread, and pastries.

The trade-off is a reduction in flavor and nutritional value. The complex, nutty flavors and the minerals found in the bran and germ are almost entirely absent.

The Case for High-Ash Flour

Flours with higher ash content deliver superior flavor, a darker and more interesting color, and significantly more nutrition. They produce breads with a more rustic, complex, and satisfying character.

The downside is compromised gluten development. The sharp bran particles physically cut through the gluten network, leading to a denser crumb and lower loaf volume. These flours also tend to absorb more water.

Choosing the Right Flour Based on Ash Content

Your ideal flour depends entirely on the characteristics you want in your final product. Ash content is the technical specification that allows you to select flour with precision.

- If your primary focus is delicate texture and a bright white crumb (like in angel food cake or enriched sandwich bread): Opt for a low-ash patent flour, typically below 0.50%.

- If your primary focus is a strong, chewy crumb with good volume (like in classic sourdough or baguettes): A medium-ash bread flour (typically 0.50% to 0.58%) offers the best balance of performance and flavor.

- If your primary focus is rustic flavor and maximum nutrition (like in whole-grain or hearth loaves): Choose a high-ash flour (0.60% and above) or a whole wheat flour (1.50%+) and be prepared to adjust your hydration and technique accordingly.

By understanding ash content, you move beyond marketing claims and select your most critical ingredient based on its fundamental properties.

Summary Table:

| Flour Type | Typical Ash Content | Key Characteristics | Best Used For |

|---|---|---|---|

| Low-Extraction (Patent) | < 0.50% | Bright white color, high gluten strength, delicate texture | Cakes, pastries, white sandwich bread |

| Medium-Extraction (Bread) | 0.50% - 0.58% | Balanced flavor, good volume, chewy crumb | Sourdough, baguettes, artisan bread |

| High-Extraction (Whole Wheat) | > 0.60% (up to 1.50%+) | Dark color, robust flavor, high nutrition | Whole grain bread, rustic hearth loaves |

Ready to achieve precision in your flour analysis and baking results?

At KINTEK, we specialize in providing laboratory equipment and consumables for accurate ash content determination and quality control. Whether you're a miller optimizing extraction rates or a baker selecting the perfect flour, our analytical solutions deliver the reliability you need.

Contact us today to discuss how our expertise can enhance your product quality and consistency.

Get in touch with our experts now!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why does melting require energy? Unlock the Science of Latent Heat and Phase Changes

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- Does heat capacity affect melting point? Unraveling the Key Differences in Thermal Properties

- What is ramp rate and how does that affect a melting point measurement? Master the Key to Accurate Thermal Analysis

- What is done by ashing in muffle furnace? A Guide to Precise Inorganic Content Analysis