In the world of advanced ceramics, density is arguably the most critical property because it directly governs the material's final performance. It serves as the primary indicator of a ceramic's mechanical strength, hardness, and resistance to environmental factors. A ceramic with higher density almost always translates to a component with superior durability and reliability.

The central concept to grasp is that density is important because it is the inverse of porosity. The real focus isn't on the material that's present, but on the empty space—the pores—that isn't. These pores act as microscopic defects that ultimately control the performance of the entire component.

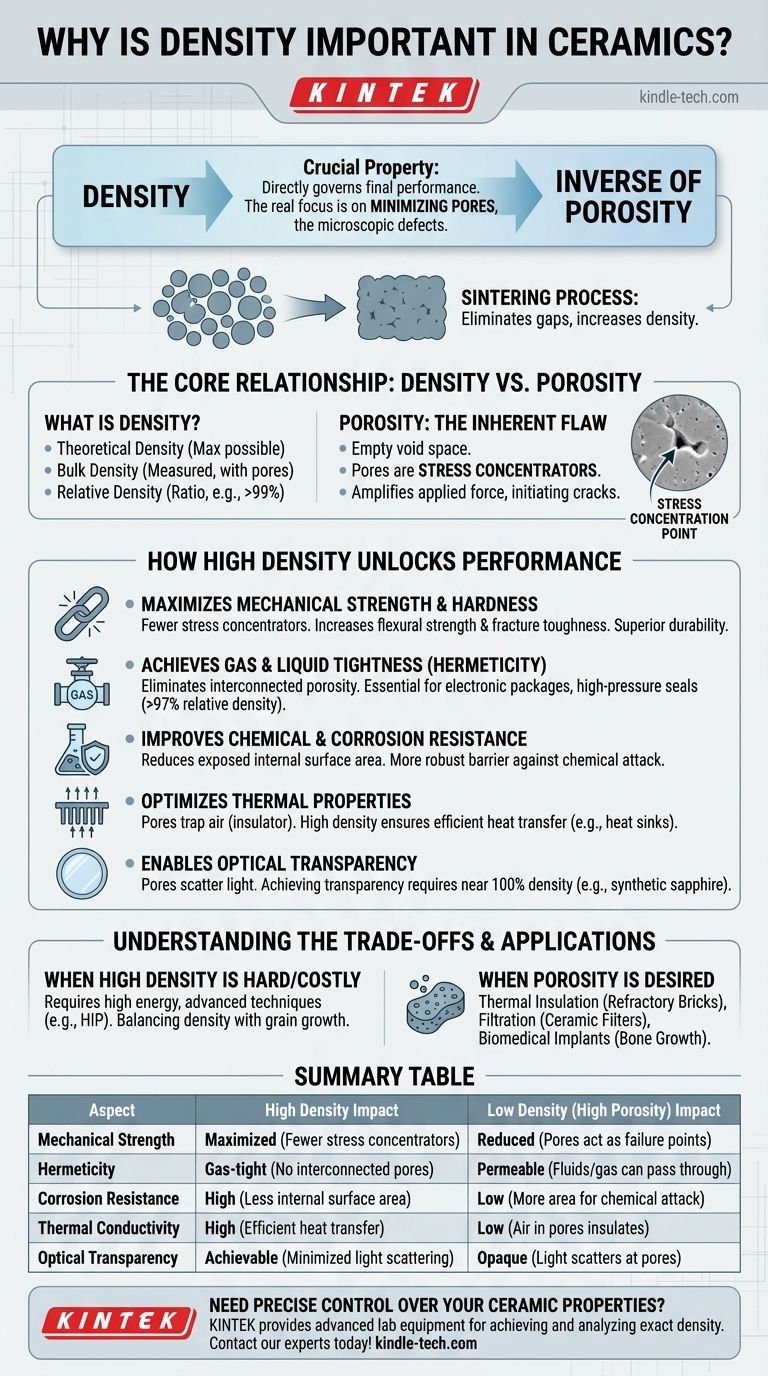

The Core Relationship: Density vs. Porosity

To understand why density matters, we must first examine its relationship with porosity, the true determining factor in a ceramic's behavior.

What We Mean by "Density"

In ceramics, we discuss two types of density. Theoretical density is the maximum possible density calculated from the material's atomic weight and crystal structure.

Bulk density is the actual measured density of a fabricated part, which is almost always lower due to the presence of pores. The ratio between these two, called relative density, is the most common metric used, with values often exceeding 99% for high-performance applications.

Porosity: The Inherent Flaw

Porosity is simply the measure of empty void space within a ceramic body. During processing, small gaps exist between the initial powder particles.

The goal of the firing process, known as sintering, is to eliminate these gaps, causing the part to shrink and densify. Any pores that remain are the primary source of failure in most ceramics.

Why Pores Are So Detrimental

A pore is not just an empty space; it's a stress concentrator. When a load is applied to a ceramic part, the stress flows around these internal voids.

This concentrates the force at the sharpest point of the pore, amplifying it many times over. This localized, amplified stress can easily initiate a crack, even if the overall applied force is low.

How High Density Unlocks Performance

By minimizing porosity and thus increasing density, we directly enhance the properties that make ceramics valuable materials for demanding applications.

Maximizing Mechanical Strength and Hardness

Fewer pores mean fewer stress concentrators. This drastically increases a ceramic's flexural strength (ability to resist bending) and fracture toughness (ability to resist crack propagation).

A dense ceramic distributes stress more evenly, allowing it to withstand much higher loads before failure. This same principle applies to hardness and wear resistance, as a solid, dense surface is much more difficult to scratch or abrade.

Achieving Gas and Liquid Tightness (Hermeticity)

For applications like electronic packages, vacuum tubes, or high-pressure seals, impermeability is essential. Pores can link together to form a continuous path through the material.

High densification (typically >97% relative density) eliminates this interconnected porosity, making the ceramic part completely gas-tight, or hermetic.

Improving Chemical and Corrosion Resistance

Pores are internal surfaces. A ceramic with high porosity has a vastly larger surface area exposed to its environment compared to a fully dense part.

This increased surface area provides more sites for chemical attack, accelerating corrosion and degradation. A dense, smooth surface acts as a far more robust barrier.

Optimizing Thermal and Optical Properties

Pores are typically filled with air, which is an excellent thermal insulator. In applications requiring high thermal conductivity, such as heat sinks, porosity must be eliminated to ensure efficient heat transfer through the ceramic's crystal lattice.

For transparent ceramics, such as synthetic sapphire for windows, pores are catastrophic. They have a different refractive index than the ceramic material, causing them to scatter light and make the material appear opaque. Achieving transparency requires a density of nearly 100%.

Understanding the Trade-offs

While high density is often the goal, it is not always necessary or even desirable. The pursuit of maximum density comes with important considerations.

The Cost and Difficulty of Full Densification

Achieving densities greater than 99% requires significant energy. This often means higher sintering temperatures, longer furnace times, or the use of advanced and expensive techniques like Hot Isostatic Pressing (HIP). The final percentage points of density are always the most difficult and costly to achieve.

When Porosity Is a Desired Feature

In some applications, porosity is intentionally engineered into the material.

- Thermal Insulation: Refractory bricks for furnaces are designed with high porosity to trap air and reduce heat transfer.

- Filtration: Ceramic filters rely on controlled, interconnected porosity to allow fluids to pass through while trapping particulates.

- Biomedical Implants: Porous coatings on implants encourage bone tissue to grow into the component, securing it in place.

The Sintering vs. Grain Growth Dilemma

The process of sintering, which increases density, also causes the individual crystalline grains of the ceramic to grow larger. While high density is good, excessively large grains can sometimes reduce fracture toughness. This creates a processing challenge: maximizing density while controlling grain growth to achieve the optimal combination of properties.

Matching Density to Your Application

The ideal density for a ceramic component is dictated entirely by its intended function.

- If your primary focus is maximum strength, wear resistance, or hermeticity: Aim for the highest achievable density (typically >99.5%) to minimize porosity, which acts as the primary failure point.

- If your primary focus is thermal insulation: Intentionally designed, high porosity is your goal, as the trapped air within the pores significantly reduces heat transfer.

- If your primary focus is fluid filtration or biomedical scaffolding: Controlled porosity, with a specific pore size and interconnectivity, is the critical design parameter, not maximum density.

Ultimately, understanding and controlling density is the key to engineering a ceramic material that precisely meets the demands of its application.

Summary Table:

| Aspect | High Density Impact | Low Density (High Porosity) Impact |

|---|---|---|

| Mechanical Strength | Maximized (Fewer stress concentrators) | Reduced (Pores act as failure points) |

| Hermeticity | Gas-tight (No interconnected pores) | Permeable (Fluids/gas can pass through) |

| Corrosion Resistance | High (Less internal surface area) | Low (More area for chemical attack) |

| Thermal Conductivity | High (Efficient heat transfer) | Low (Air in pores insulates) |

| Optical Transparency | Achievable (Minimized light scattering) | Opaque (Light scatters at pores) |

Need precise control over your ceramic properties? The density of your ceramic components is fundamental to their performance. KINTEK specializes in providing the advanced lab equipment and consumables necessary for achieving and analyzing the exact density required for your application, whether you need maximum strength, controlled porosity for filtration, or thermal insulation. Let our expertise help you engineer ceramics that meet your most demanding specifications. Contact our experts today to discuss your laboratory needs!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C

- What are the properties and applications of silicon carbide ceramics? Solve Extreme Engineering Challenges