When selecting a corrosion protection strategy, stainless steel is often considered superior to a coating because its resistance is an inherent property of the metal itself, not just a surface layer. While a coating acts as a barrier that can be compromised, stainless steel contains chromium, which forms a self-healing, invisible passive layer that instantly reforms when scratched. This fundamental difference makes it more durable and reliable in many applications.

The core decision is not about which method is universally "better," but whether your application demands the inherent, self-healing protection of an alloy like stainless steel or the versatile, applied protection of a surface coating. The right choice depends entirely on the environment, lifetime requirements, and risk of physical damage.

The Fundamental Difference: Inherent vs. Applied Protection

To make an informed decision, you must first understand how each method fundamentally works. They are not just different solutions; they are different philosophies of protection.

How Stainless Steel Resists Corrosion

The "stainless" property comes from alloying, specifically by mixing a minimum of 10.5% chromium into the iron.

Chromium reacts with oxygen in the air or water to form a very thin, stable, and transparent film on the surface called the passive layer.

This layer is the key. If the surface is scratched, abraded, or cut, the exposed chromium almost instantly reacts with oxygen and reforms the protective layer, effectively healing itself.

How Coatings Provide Protection

Coatings work by creating a protective layer on top of a base metal, most often carbon steel. There are two primary mechanisms.

First is barrier protection, where the coating physically isolates the steel from the corrosive environment (oxygen and moisture). Most paints and epoxies work this way.

Second is sacrificial protection, where the coating is made of a more reactive metal (like zinc in galvanizing). This zinc coating corrodes preferentially, "sacrificing" itself to protect the steel underneath.

Key Advantages of Stainless Steel

The inherent nature of stainless steel's protection leads to several distinct advantages over a coated material.

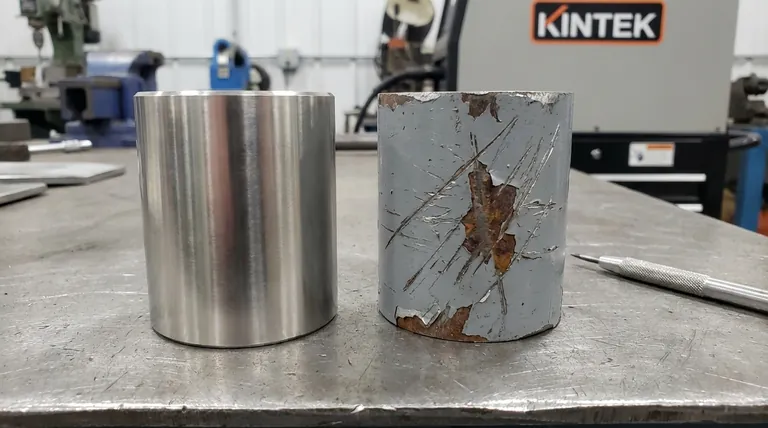

Self-Healing and Damage Tolerance

This is the most significant advantage. A scratch on a coated surface is a breach. It creates a direct path for corrosion to begin, often creeping under the coating and causing it to peel and fail.

A scratch on stainless steel is a non-event from a corrosion perspective. The passive layer heals, and protection is fully restored without any intervention.

Longevity and Reduced Maintenance

Because it doesn't rely on a finite surface layer, stainless steel offers exceptional longevity with minimal maintenance. There is no need for periodic inspection for coating damage, touch-ups, or complete re-coating cycles.

This dramatically lowers the total cost of ownership over the life of the equipment or structure, even if the initial material cost is higher.

Purity and Contamination Control

In industries like food processing, pharmaceuticals, or medical devices, product purity is critical. A failing coating can flake off, creating a source of contamination.

Stainless steel provides a stable, non-reactive surface that will not degrade and contaminate the product, ensuring higher levels of hygiene and safety.

Understanding the Trade-offs: When a Coating Is the Right Choice

An objective analysis shows that stainless steel is not the automatic winner in every scenario. Coatings offer unique advantages that make them the superior choice in specific contexts.

The Impact of Upfront Cost

The initial procurement cost of stainless steel is significantly higher than that of carbon steel. For large-scale projects or cost-sensitive applications, using a high-performance coating system on carbon steel is often the more economically viable solution.

Retrofitting and Field Application

You cannot convert an existing carbon steel structure into stainless steel. Coatings are the only practical method for protecting assets that are already in place. Their ability to be applied in the field is a massive operational advantage.

Specific Chemical Resistance

While broadly resistant, certain grades of stainless steel can be vulnerable to specific aggressive chemicals, particularly chlorides, which can cause pitting corrosion.

In these niche industrial environments, a specialized coating engineered for that exact chemical exposure can offer more reliable protection than a general-purpose stainless steel.

Making the Right Choice for Your Application

Your final decision should be guided by the specific goals and constraints of your project.

- If your primary focus is long-term reliability and minimal maintenance: Stainless steel is the superior choice due to its self-healing nature and reduced lifetime costs.

- If your primary focus is managing upfront project costs: A high-performance coating on a less expensive base metal is almost always the most economical initial solution.

- If you are protecting an existing structure or require field repairs: A coating system is your only practical and flexible option.

- If your environment involves highly specific chemical attacks: A specialized coating engineered for that threat may outperform even high-grade stainless steel alloys.

Ultimately, understanding the fundamental difference between inherent and applied protection is the key to selecting the most effective and economical strategy for your project's lifetime.

Summary Table:

| Protection Method | Key Mechanism | Primary Advantage | Best For |

|---|---|---|---|

| Stainless Steel | Self-healing chromium oxide layer | Damage tolerance & minimal maintenance | Long-term reliability, hygiene-critical applications |

| Surface Coating | Barrier or sacrificial layer | Lower upfront cost & field application | Budget-sensitive projects, existing structures |

Need Corrosion-Resistant Lab Equipment?

Choosing the right corrosion protection is critical for your laboratory's performance and safety. At KINTEK, we specialize in high-quality lab equipment and consumables designed with durable materials to meet your specific environmental challenges.

✅ Get expert guidance on selecting equipment with optimal corrosion protection for your application ✅ Ensure long-term reliability with materials that reduce maintenance and contamination risks ✅ Optimize your total cost of ownership with solutions built for durability

Let our specialists help you select the perfect equipment for your lab's unique needs. Contact KINTEK today for personalized recommendations and quotes!

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Warm Isostatic Press for Solid State Battery Research

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- Why KBr is used to prepare samples for FTIR analysis? Unlock Clear, High-Quality Spectra

- Is pyrolysis oil toxic? Understanding the Health and Safety Risks of Bio-Oil

- What are the parameters of sputtering? Master the 4 Key Variables for Perfect Thin Films

- What is the speed of Rotavap? Optimize Evaporation with the Right RPM for Your Solvent

- How does the refrigeration system of an Ultra Freezer work? The Two-Stage Cascade Cooling Explained

- What is used as a source of heat in the laboratory? Choose the Right Tool for Safe & Precise Heating

- What is KBr used for in IR spectroscopy? Master the Pellet Method for Clear Spectra

- What is the product of physical vapor deposition? A High-Performance Thin Film Coating