Determining the ash content of food is a fundamental analytical process used to measure the total amount of inorganic, non-combustible material. This measurement serves as a direct indicator of the total mineral content within a foodstuff. It is a critical parameter for nutrition, quality control, and ensuring product authenticity.

Ash content analysis is not simply a measure of minerals; it is a foundational indicator of a food's nutritional profile, quality, and adherence to processing standards. It provides a crucial window into the non-organic components that define a product's character and safety.

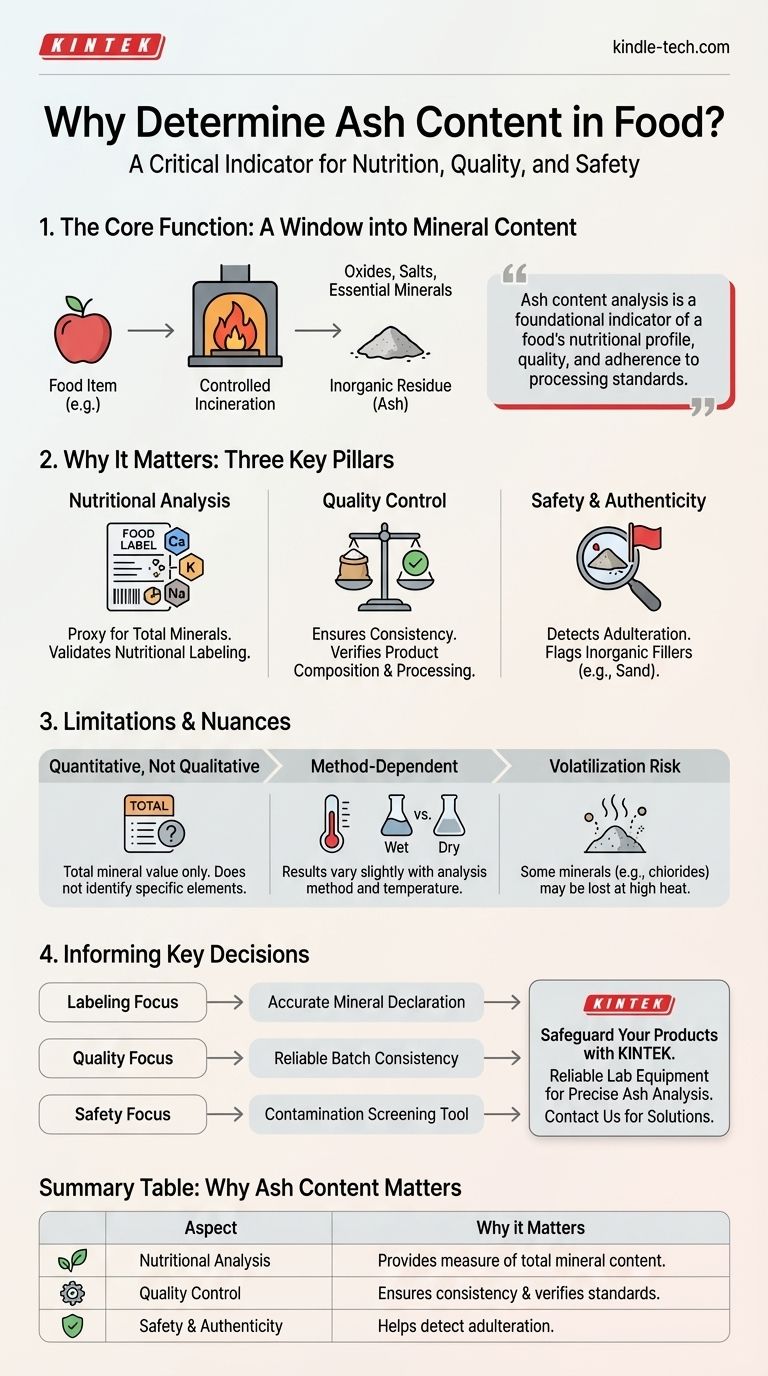

The Core Function: A Window into Mineral Content

Ash analysis is a process of controlled incineration, where all organic matter (fats, proteins, carbohydrates) is burned away, leaving only the inorganic residue behind. This residue is what we refer to as "ash."

Defining "Ash"

The ash itself is the collection of oxides and salts of the inorganic elements present in the original food. This includes essential minerals like calcium, potassium, sodium, and magnesium, as well as trace elements.

A Proxy for Nutrition

The primary reason for measuring ash is to quantify the nutritional mineral content. While it doesn't identify individual minerals, the total ash value is a crucial starting point for nutritional labeling and for verifying fortification claims.

A Critical Tool for Quality Control and Consistency

Beyond nutrition, ash content is a powerful and surprisingly versatile metric for quality assurance in food production. Its value often serves as a benchmark for product identity and purity.

Verifying Product Composition

Many food products have a specific, expected ash content. For example, in flour milling, a higher ash content indicates more of the bran and germ remain, which affects the flour's quality and baking properties. Mills use this measurement to ensure their refining process is consistent.

Detecting Adulteration

An unusually high ash content can be a red flag for adulteration. The intentional addition of cheap, inorganic fillers—such as sand, chalk, or talc—to increase a product's weight would dramatically and illegally increase the ash value.

Confirming Processing Standards

Changes in processing can alter ash content. For instance, if a fruit is not peeled correctly before being turned into a puree, the resulting product may have a higher ash content due to minerals in the skin. This allows manufacturers to monitor the consistency of their production line.

Understanding the Limitations and Nuances

While incredibly useful, it's important to understand what ash analysis does and does not reveal. Objectivity requires acknowledging its limitations.

It's a Quantitative, Not Qualitative, Measure

The single most important limitation is that ash content gives a total mineral value only. It cannot distinguish between essential minerals like potassium and contaminants like lead. Further, more specific analysis is required to identify and quantify individual elements.

Method-Dependent Results

The final ash value can be slightly influenced by the analysis method used (e.g., dry ashing vs. wet ashing) and the temperature of the furnace. For this reason, consistency in testing protocol is essential for comparing results over time.

Potential for Volatilization

Certain minerals, like chlorides and nitrates, can be lost or "volatilized" at the very high temperatures used in ashing. This can lead to an underestimation of the true total mineral content, a factor that trained analysts must consider.

How Ash Content Informs Key Decisions

The application of ash analysis depends entirely on the specific goal of the test. It is a simple measurement that answers different questions for different professionals.

- If your primary focus is nutritional labeling: Ash analysis is the first step in validating the total mineral content declared on a food panel.

- If your primary focus is quality assurance: It serves as a reliable benchmark to ensure product consistency batch after batch, particularly in processed goods like flour, spices, and dairy powders.

- If your primary focus is food safety and authenticity: An unexpected ash value is a powerful screening tool that can trigger deeper investigation into potential contamination or economic adulteration.

Ultimately, measuring ash content provides a simple yet powerful metric for safeguarding the nutritional value, quality, and integrity of food products.

Summary Table:

| Aspect | Why Ash Content Matters |

|---|---|

| Nutritional Analysis | Provides a measure of total mineral content for accurate labeling. |

| Quality Control | Ensures product consistency and verifies processing standards (e.g., in flour milling). |

| Safety & Authenticity | Helps detect adulteration with inorganic fillers like sand or chalk. |

Ensure the quality and safety of your food products with precise ash content analysis. KINTEK specializes in providing reliable lab equipment for accurate food testing. Our muffle furnaces and consumables are designed to deliver consistent results for your quality control and nutritional labeling needs. Contact our experts today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What happens in the muffle furnace? Achieve Pure, Uniform High-Temperature Processing

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- Is sintering the same as welding? Key Differences in Material Bonding and Fusion Explained

- What is the mechanism of a muffle furnace? Master Precise, Contaminant-Free Heating

- What is dry ashing? A Reliable Method for Analyzing Inorganic Composition