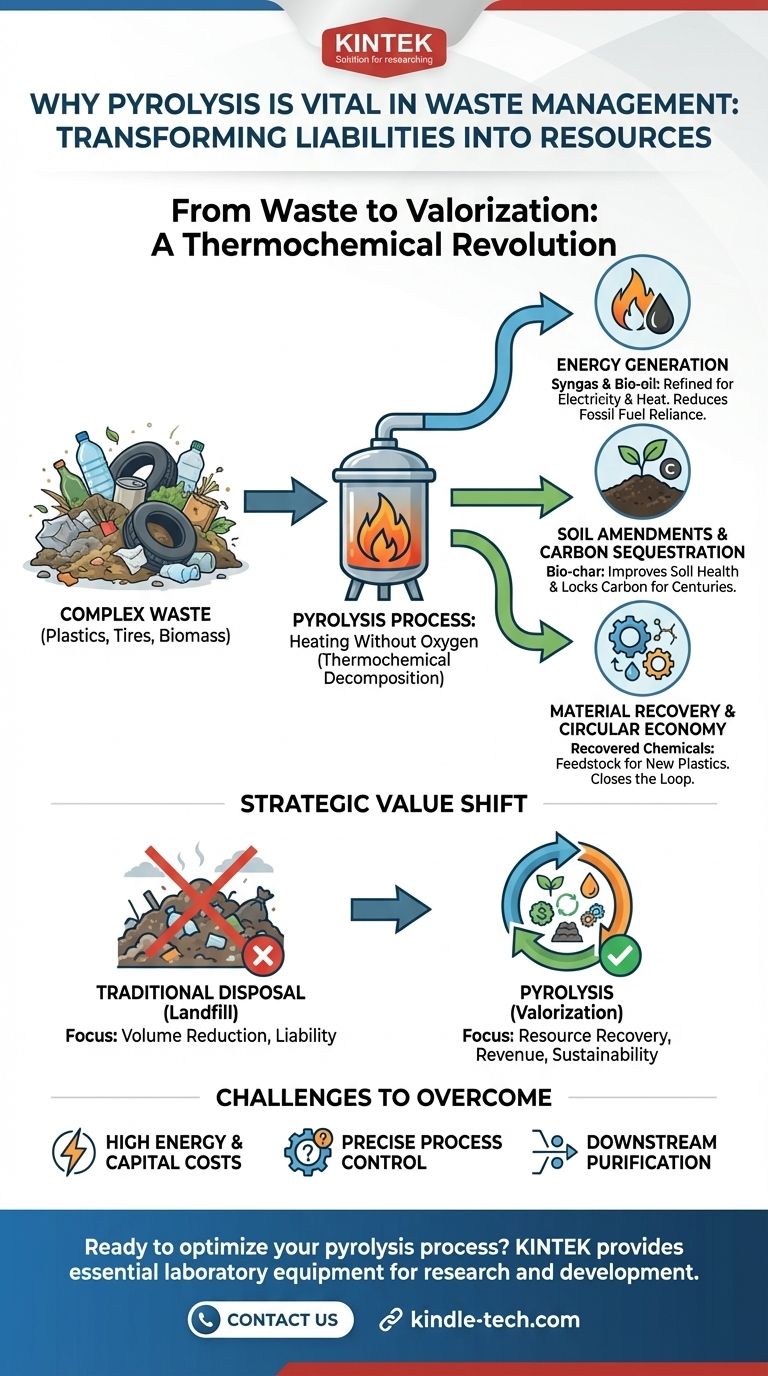

In essence, pyrolysis is important because it chemically transforms waste from a liability into a source of valuable resources. It provides a strategic alternative to traditional disposal methods like landfills by breaking down complex waste materials—such as plastics, tires, and biomass—into marketable products like fuel and soil amendments, fundamentally changing the economics and environmental impact of waste management.

The core value of pyrolysis is not merely waste destruction, but waste valorization. It shifts the paradigm from simply getting rid of waste to recovering and converting its inherent chemical energy and material value.

What is Pyrolysis in Waste Management?

Pyrolysis is a thermochemical decomposition process. In simple terms, it involves heating waste materials to high temperatures in an environment completely devoid of oxygen.

The Core Mechanism: Heating Without Oxygen

The absence of oxygen is the critical factor that distinguishes pyrolysis from incineration. While incineration burns waste, pyrolysis causes it to break down chemically without combustion.

This decomposition splits complex organic molecules into simpler, more valuable compounds. The process can be thought of as "baking" the waste in a sealed oven rather than burning it in an open fire.

Key Inputs: What Waste Can Be Processed?

Pyrolysis is particularly effective for organic and carbon-based waste streams that are difficult to recycle conventionally.

Common feedstocks include post-consumer plastics, end-of-life tires, and organic biomass like agricultural residue. These materials are rich in chemical energy that pyrolysis can unlock.

The Strategic Value of Pyrolysis Outputs

The true importance of pyrolysis lies in the usefulness of its three primary outputs. By converting waste into these products, it supports both energy independence and a more circular economy.

Generating Energy with Syngas and Bio-oil

Pyrolysis produces a combustible gas (syngas) and a liquid fuel (bio-oil). After refinement, both can be used to generate electricity or heat, effectively turning a waste stream into a local energy source.

This reduces reliance on fossil fuels and provides a sustainable outlet for non-recyclable materials.

Creating Soil Amendments with Bio-char

The solid residue of pyrolysis is a stable, carbon-rich material called bio-char. When added to soil, it can improve water retention, nutrient availability, and overall soil health.

Crucially, bio-char acts as a form of carbon sequestration, locking carbon in the soil for centuries and helping to mitigate climate change. It can also be a feedstock for producing high-grade activated carbon.

Recovering Materials for a Circular Economy

For specific waste streams like plastics and rubber, pyrolysis can break them down into their basic chemical components. These recovered materials can then serve as a feedstock for producing new plastics or other chemicals.

This process reduces the need for virgin raw materials, decreases the environmental impact of extraction, and closes the loop in a circular economy.

Understanding the Trade-offs and Challenges

While promising, pyrolysis is not a silver bullet. A clear-eyed assessment requires understanding its operational and economic hurdles.

Significant Energy Requirements

Pyrolysis is an energy-intensive process that requires heating materials to very high temperatures. For the system to be environmentally and economically positive, the energy recovered from the outputs must exceed the energy consumed by the process.

High Capital Costs

The initial investment for a pyrolysis plant, including the reactor, control systems, and product refinement equipment, can be substantial. This high barrier to entry can make it challenging for smaller municipalities or companies to adopt.

The Need for Precise Process Control

Efficiency and product quality depend heavily on maintaining specific process conditions, such as temperature, heating rate, and feedstock consistency. Any deviation can result in lower-value outputs or process inefficiencies.

Downstream Product Purification

The raw syngas, bio-oil, and bio-char are rarely pure enough for immediate use. They often require significant separation and purification before they can be sold or used as fuel or chemical feedstock, adding complexity and cost to the operation.

Making the Right Choice for Your Goal

Adopting pyrolysis requires aligning the technology with a specific strategic objective. Its value is not universal but depends entirely on your primary goal.

- If your primary focus is landfill diversion: Pyrolysis is an extremely effective method for dramatically reducing the volume and mass of solid waste requiring disposal.

- If your primary focus is revenue generation: Success depends on your ability to efficiently refine and find stable markets for the bio-oil, syngas, and bio-char outputs.

- If your primary focus is environmental sustainability: The key is to ensure the system is net energy positive and that the full lifecycle emissions—from transport to processing—are lower than alternative disposal methods.

When deployed correctly, pyrolysis serves as a powerful tool for transforming our relationship with waste from one of disposal to one of resource recovery.

Summary Table:

| Key Aspect | Why It Matters in Waste Management |

|---|---|

| Core Process | Heats waste without oxygen, preventing harmful emissions from burning (incineration). |

| Primary Inputs | Processes hard-to-recycle materials like plastics, tires, and biomass. |

| Valuable Outputs | Produces bio-oil & syngas (for energy), bio-char (for soil health), and recovered chemicals. |

| Main Benefit | Transforms waste from a disposal cost into a source of revenue and sustainable resources. |

| Key Consideration | Requires significant energy input and capital investment for efficient operation. |

Ready to transform your waste stream into valuable resources?

KINTEK specializes in providing robust laboratory equipment and consumables essential for researching, developing, and optimizing pyrolysis processes. Whether you are analyzing feedstock, testing process parameters, or refining output products, our solutions help you achieve efficient and scalable waste valorization.

Contact us today using the form below to discuss how our equipment can support your specific waste management and circular economy goals.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- At what temperature is conventional pyrolysis done? Unlock the Right Temperature for Your Desired Product

- What are the factors affecting the yield of bio-oil from the pyrolysis of coconut shell? Control 4 Key Parameters

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity