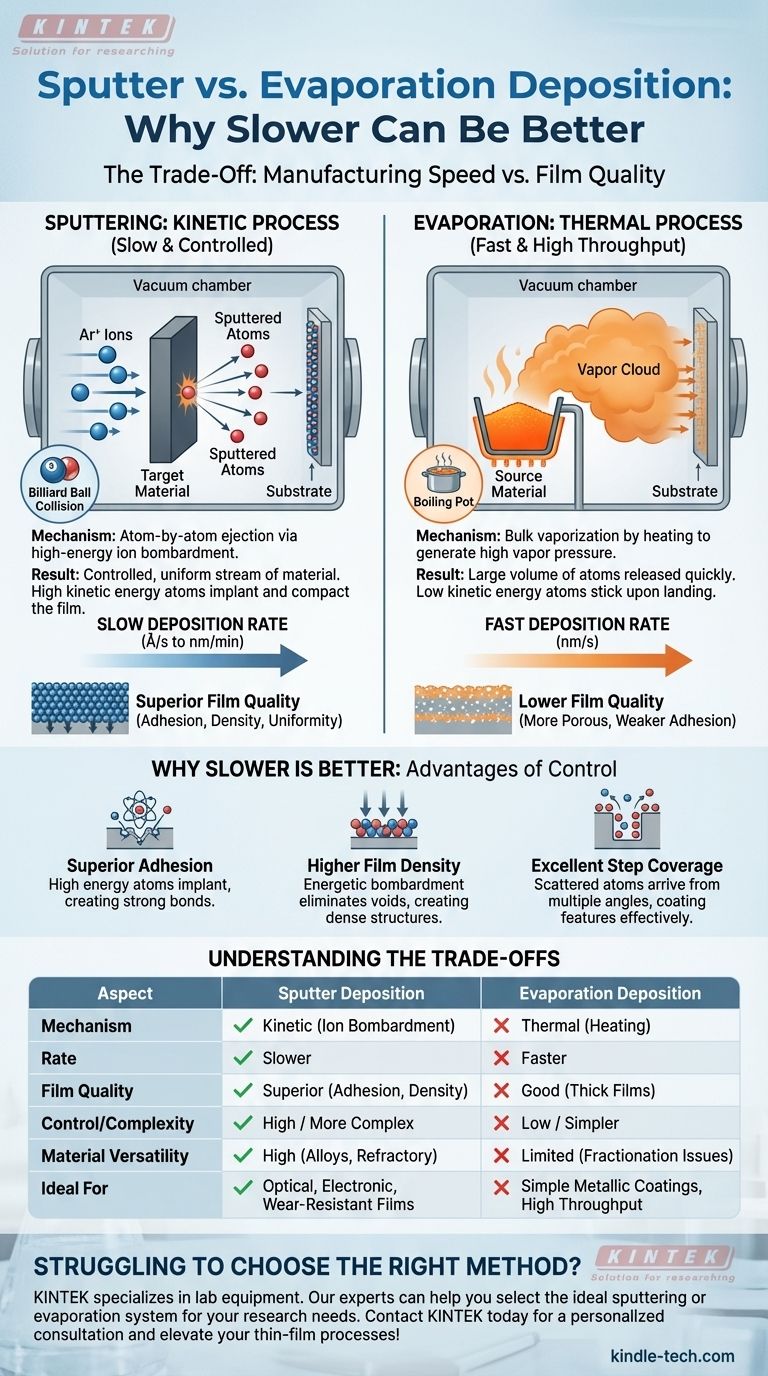

The fundamental difference in deposition speed comes down to the physical mechanism used to liberate material from the source. Sputter deposition is a kinetic process that ejects atoms one by one through high-energy ion bombardment, making it inherently slow and controlled. In contrast, thermal evaporation is a bulk thermal process that generates a dense cloud of vapor by heating the source material, resulting in a much faster deposition rate.

The choice between sputtering and evaporation is not merely about speed; it's a critical trade-off between manufacturing throughput and the final quality of the thin film. Sputtering's deliberate, atom-by-atom pace is the very reason it produces films with superior adhesion, density, and uniformity.

The Mechanics of Material Ejection: Atom vs. Vapor

To understand the speed difference, you must first visualize how each process removes atoms from the target material. The methods are fundamentally different, one being kinetic and the other thermal.

Sputtering: A Kinetic Billiard Ball Collision

In sputtering, the chamber is filled with an inert gas, typically Argon. A strong electric field ionizes this gas, creating a plasma, and accelerates the positive Argon ions toward the negatively charged source material (the "target").

These energetic ions act like atomic-scale billiard balls, crashing into the target surface and physically knocking out, or "sputtering," individual atoms or small clusters. This is a momentum-transfer process, and its efficiency is relatively low, resulting in a controlled but slow stream of ejected material.

Evaporation: A Bulk Thermal Process

Thermal evaporation is much more straightforward, analogous to boiling a pot of water. The source material is placed in a crucible and heated in a high vacuum until its temperature rises to the point where its vapor pressure becomes significant.

At this temperature, a large volume of atoms sublimes or evaporates from the surface, creating a dense vapor cloud that travels outward and condenses on the cooler substrate. Because this is a bulk thermodynamic effect rather than a one-for-one collision, it can release vastly more material in the same amount of time.

Why Slower Can Be Better: The Advantages of Control

If evaporation is so much faster, sputtering would not be used unless its slower rate provided significant benefits. The high kinetic energy of sputtered atoms is the key to these advantages.

Superior Film Adhesion

Sputtered atoms arrive at the substrate with significantly higher energy (typically 1-10 eV) compared to evaporated atoms (<1 eV). This extra energy allows them to implant slightly into the substrate surface, creating a strong, intermixed bond layer that dramatically improves film adhesion.

Higher Film Density

The energetic bombardment of the growing film by sputtered atoms helps to "knock" them into place, eliminating voids and creating a much denser, more uniform film structure. Evaporated atoms land with low energy and tend to stick where they land, which can result in more porous films.

Excellent Step Coverage

In sputtering, the ejected atoms can scatter off the background gas on their way to the substrate. This scattering effect means atoms arrive from a wider range of angles, allowing them to coat the sides of microscopic trenches and features more effectively, a property known as "step coverage."

Understanding the Trade-offs

Choosing a deposition method requires weighing the speed against the desired outcome for your specific application. There is no single "best" method.

Deposition Rate vs. Film Quality

This is the central trade-off. Evaporation offers high speed, which is ideal for thick films or high-throughput manufacturing where supreme quality is secondary. Sputtering offers superior film properties (density, adhesion, purity) at the cost of significantly longer process times.

Process Complexity and Control

Sputtering is a more complex process involving gas flow, plasma management, and multiple power sources. However, this complexity provides more "knobs" to turn for fine-tuning film properties like stress and stoichiometry, especially for complex materials. Evaporation is mechanically simpler but offers less control over the final film structure.

Material Compatibility

Sputtering can deposit virtually any material, including alloys and refractory metals with very high melting points. Evaporation struggles with alloys containing elements that have different vapor pressures, as the more volatile element will evaporate first, changing the composition of the film.

Making the Right Choice for Your Goal

Your decision should be dictated entirely by the requirements of your final product.

- If your primary focus is maximum throughput or simple metallic coatings: Choose thermal evaporation for its speed and simplicity.

- If your primary focus is high-performance optical, electronic, or wear-resistant films: Choose sputter deposition for its superior adhesion, density, and control.

- If your primary focus is depositing complex alloys or compounds with precise composition: Choose sputter deposition, as it preserves the stoichiometry of the target material.

Ultimately, the deposition rate is a direct consequence of the physics behind the method, which in turn dictates the energy of the deposited atoms and the resulting quality of your film.

Summary Table:

| Aspect | Sputter Deposition | Evaporation Deposition |

|---|---|---|

| Primary Mechanism | Kinetic (Ion Bombardment) | Thermal (Heating/Vaporization) |

| Typical Deposition Rate | Slower (Å/s to nm/min) | Faster (nm/s) |

| Key Advantage | Superior Film Quality (Adhesion, Density) | High Throughput & Speed |

| Ideal For | High-performance optical, electronic, wear-resistant films | Simple metallic coatings, thick films |

Struggling to choose the right deposition method for your lab's specific film requirements? The trade-off between speed and quality is critical. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the ideal sputtering or evaporation system to achieve the precise film properties—superior adhesion, density, or high throughput—your research demands. Contact KINTEK today for a personalized consultation and elevate your thin-film processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is sputtered film? An In-Depth Look at Atomic-Level Coating Technology

- Do CVD diamonds have resale value? The Truth About Lab-Grown Diamond Investment

- What is the structure of carbon nanomaterials? Unlocking Their Atomic Architecture for Innovation

- What is the synthesis and mechanism involved in the preparation of carbon nanotubes using CVD process? Master Controlled Growth for Your Application

- What materials are CVD deposition? From Semiconductors to Super-Hard Coatings

- What are the advantages of sputtering based thin film deposition? Achieve Superior Film Quality & Material Versatility

- What materials are needed for thin film? Metals, Oxides, and Semiconductors for Your Application

- What are the catalysts used in CVD? Unlocking Nanomaterial Growth with Metal Catalysts