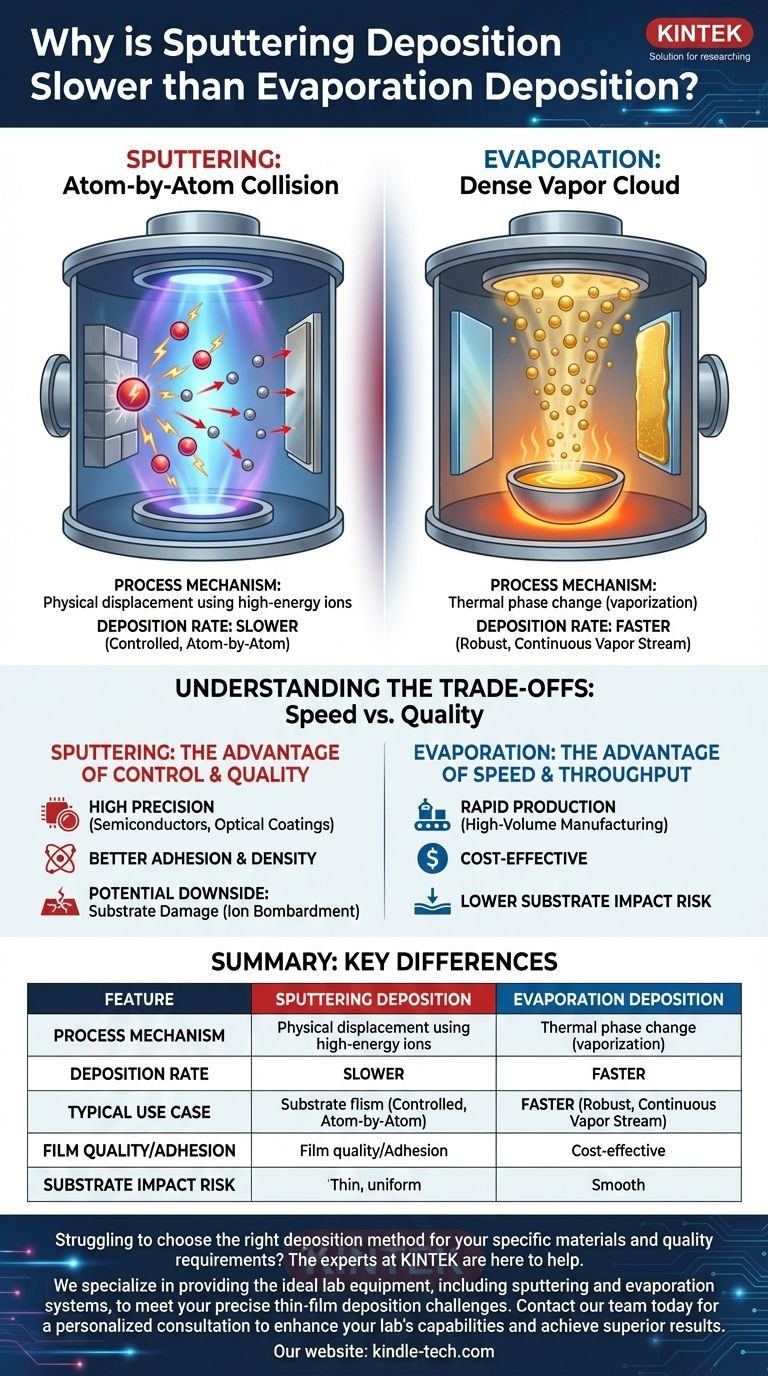

The core difference is mechanical. Sputtering is slower because it is a physical displacement process, using high-energy ions to knock individual atoms off a target material one by one. In contrast, thermal evaporation is a phase-change process that heats a material until it creates a dense, continuous cloud of vapor, depositing material at a much higher volume.

The choice between sputtering and evaporation is a classic engineering trade-off between speed and control. Evaporation prioritizes high deposition rates for rapid production, while the inherent slowness of sputtering is a direct consequence of a more controlled, atom-by-atom mechanism that produces higher-quality films.

The Fundamental Difference in Material Ejection

To understand the speed difference, you must first understand how each process liberates atoms from the source material. The two methods are fundamentally distinct in their physical principles.

Evaporation: Creating a Dense Vapor Cloud

Thermal evaporation functions much like boiling a pot of water. The source material is heated in a high vacuum until its temperature rises past its vaporization point.

This phase change creates a robust vapor stream—a dense cloud of atoms that travels from the source and condenses on the cooler substrate, forming a thin film.

Sputtering: A Billiard Ball Collision at the Atomic Scale

Sputtering does not rely on heat to vaporize material. Instead, it uses a plasma to generate energetic ions (typically of an inert gas like Argon).

These ions are accelerated into a solid "target" of the desired material. The collision physically dislodges or "sputters" individual atoms or small clusters, which then deposit onto the substrate.

Why This Directly Impacts Deposition Rate

The high-volume vapor stream from evaporation simply transports more material in a given period than the one-by-one atomic displacement of sputtering. Creating a continuous cloud is inherently faster than chipping away at a solid block, atom by atom.

Understanding the Trade-offs: Speed vs. Quality

The lower deposition rate of sputtering is not simply a disadvantage; it is an intrinsic part of a process that offers different benefits. The decision to use one over the other depends entirely on the desired outcome.

The Advantage of Speed: Evaporation

Because it produces a high volume of vapor quickly, evaporation is ideal for applications where throughput is critical.

It is generally more cost-effective and well-suited for high-volume production where the primary goal is to deposit a film quickly with less emphasis on microscopic perfection.

The Advantage of Control: Sputtering

The atoms ejected during sputtering have much higher kinetic energy than those from evaporation. This energy results in a film with better adhesion and a denser, more uniform structure.

Sputtering is the preferred method for applications that demand high precision and superior film quality, such as in semiconductor manufacturing or for advanced optical coatings.

A Potential Downside of Sputtering

The same high-energy bombardment that creates a quality film can also be a liability. The high-speed atoms and plasma environment can damage sensitive substrates, a factor that must be considered when choosing a deposition method.

Making the Right Choice for Your Goal

Selecting the correct deposition technique requires aligning the process capabilities with your project's primary objective.

- If your primary focus is rapid production and lower cost: Evaporation is the superior choice due to its fundamentally higher deposition rate.

- If your primary focus is film quality, adhesion, and uniformity: The slower, more energetic, and highly controlled atomic ejection of sputtering is the correct approach.

- If you are working with delicate substrates: You must weigh the high quality of sputtered films against the potential for damage from ion bombardment.

Ultimately, the "slower" deposition rate of sputtering is a feature, not a bug, enabling a level of precision that high-speed evaporation cannot match.

Summary Table:

| Feature | Sputtering Deposition | Evaporation Deposition |

|---|---|---|

| Process Mechanism | Physical displacement via ion bombardment | Thermal phase change (vaporization) |

| Deposition Rate | Slower (atom-by-atom) | Faster (dense vapor cloud) |

| Typical Use Case | High-quality, uniform films (e.g., semiconductors) | High-throughput, cost-effective coating |

| Film Quality/Adhesion | Superior | Good |

| Substrate Impact Risk | Higher (ion bombardment) | Lower |

Struggling to choose the right deposition method for your specific materials and quality requirements? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment, including sputtering and evaporation systems, to meet your precise thin-film deposition challenges. Contact our team today for a personalized consultation to enhance your lab's capabilities and achieve superior results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the limitation of sputtering process? Key Drawbacks in Thin Film Deposition

- How does an electron beam evaporator work? Achieve High-Purity Thin Film Deposition

- What is the source of electron beam evaporation? The Electron Gun Explained for High-Purity Thin Films

- What is the difference between a condenser and an evaporator? The Key to Efficient Cooling Systems

- What is the temperature of e-beam evaporation? Mastering the Two-Zone Thermal Process for Precision Films

- What are the disadvantages of thermal evaporation technique? High Impurity, Limited Materials & Poor Film Quality

- What is the source of vacuum evaporation? Energy and Vacuum for High-Purity Coatings

- What is the evaporation theory of thin films? A Guide to High-Purity Thin Film Deposition