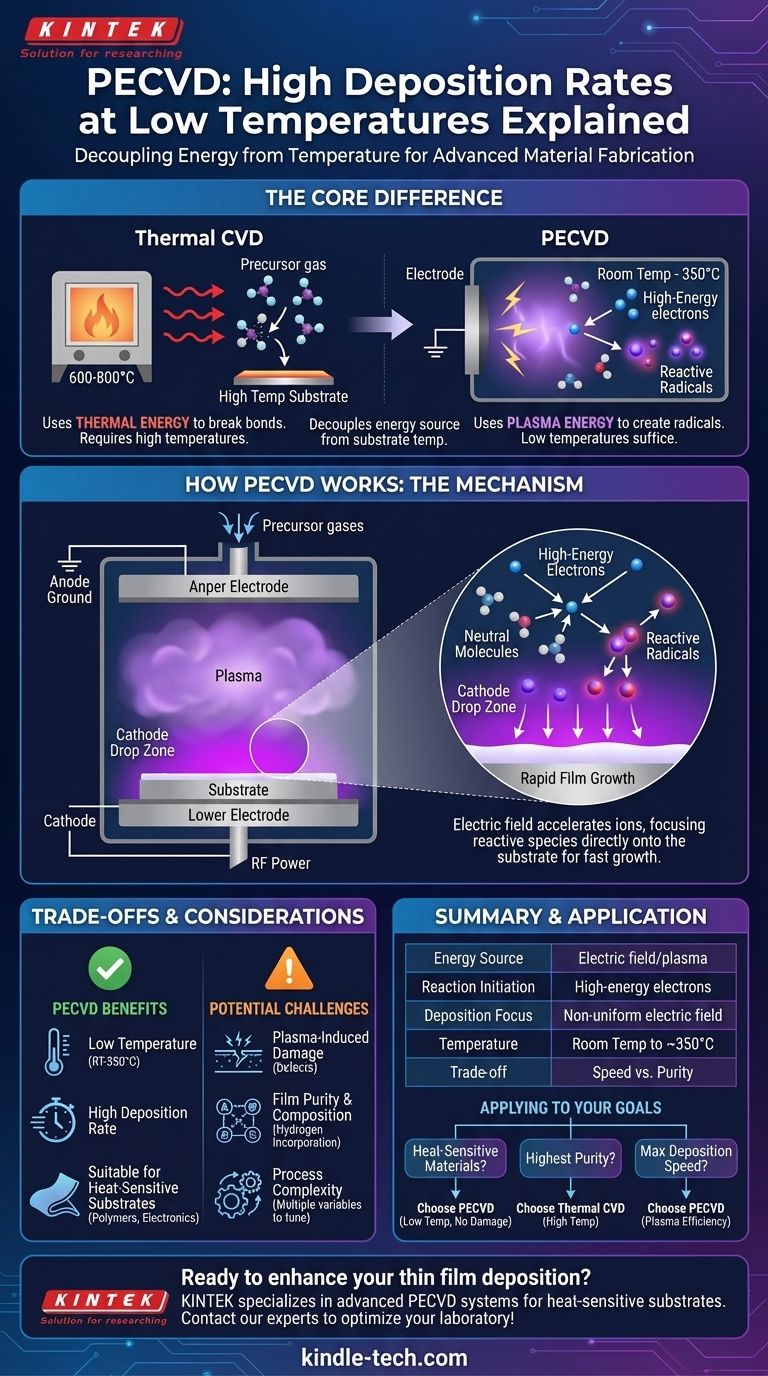

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) achieves high deposition rates at low temperatures because it uses energy from an electric field—not thermal energy—to initiate chemical reactions. A plasma is generated to create highly reactive gas molecules, and an uneven electric field concentrates these reactive species directly onto the substrate surface, accelerating film growth without needing to heat the entire system.

The critical insight is that PECVD decouples the energy source for chemical reactions from the substrate's temperature. Instead of using brute-force heat to break down precursor gases, it uses a plasma to create chemical radicals that are inherently reactive even at low temperatures.

The Core Problem: Overcoming the Energy Barrier

To understand why PECVD is effective, we must first look at the fundamental challenge of thin film deposition.

The Thermal CVD Approach

Traditional Chemical Vapor Deposition (CVD) relies on high temperatures, often exceeding 600-800°C. This intense heat provides the thermal energy necessary to break the chemical bonds of the precursor gases introduced into the reaction chamber.

The Need for Activation Energy

Once these bonds are broken, the resulting atoms or molecules can deposit onto the substrate and form a solid thin film. Without sufficient energy, the precursor gases remain stable, and no deposition occurs.

How PECVD Changes the Energy Equation

PECVD provides an alternative pathway to supply this activation energy, one that does not rely on heating the substrate to extreme temperatures.

Generating the Plasma: The New Energy Source

The process begins by applying a strong electric field to a low-pressure gas, ionizing it and creating a plasma. This plasma is a partially ionized gas containing a mix of neutral atoms, ions, and—most importantly—high-energy free electrons.

Creating Reactive Species Without Heat

These high-energy electrons collide with the neutral precursor gas molecules. The impact transfers enough energy to break the molecules' chemical bonds, creating highly reactive radicals. This is the key step: the reaction is initiated by energetic electron collisions, not by thermal vibration.

The Role of the Cathode and Electric Field

The substrate is typically placed on the cathode (the negative electrode). The electric field is highly non-uniform and is strongest in a region directly in front of this cathode, known as the cathode drop zone.

This intense field acts like a focusing lens, accelerating ions toward the substrate and concentrating the reactive radicals in the precise location where the film needs to grow. This localization dramatically increases the deposition rate and prevents reactants from being wasted on the chamber walls.

Understanding the Trade-offs

While powerful, the use of a plasma introduces unique considerations and potential downsides compared to purely thermal methods.

Plasma-Induced Damage

The energetic ions from the plasma that bombard the substrate can create defects in the growing film or in the underlying substrate itself. This can impact the material's electrical or optical properties.

Film Purity and Composition

Because the reactions are driven by complex plasma chemistry, it's possible for unwanted elements (like hydrogen from precursor gases) to become incorporated into the film. This can alter the film's density, stress, and stoichiometry.

Process Complexity

Controlling a PECVD process requires careful tuning of multiple variables beyond temperature, including RF power, pressure, gas flow rates, and chamber geometry. This can make process optimization more complex than for a simple thermal furnace.

Applying This to Your Deposition Goal

Understanding this mechanism allows you to make informed decisions based on your primary objective.

- If your primary focus is deposition on heat-sensitive materials (like polymers or pre-processed electronics): PECVD is the superior choice, as its ability to operate from room temperature to ~350°C prevents substrate damage.

- If your primary focus is achieving the highest possible film purity and crystalline quality: A high-temperature thermal CVD or annealing process may be necessary, provided your substrate can withstand the heat.

- If your primary focus is maximizing deposition speed and throughput: PECVD offers excellent rates due to the efficient, localized reaction chemistry driven by the plasma.

By substituting electrical energy for thermal energy, PECVD provides a versatile and efficient path to fabricating advanced materials.

Summary Table:

| Key Aspect | How PECVD Achieves It |

|---|---|

| Energy Source | Uses electric field/plasma instead of thermal energy. |

| Reaction Initiation | High-energy electrons create reactive radicals from precursor gases. |

| Deposition Focus | Non-uniform electric field concentrates reactive species on the substrate. |

| Typical Temperature Range | Room temperature to ~350°C, ideal for sensitive materials. |

| Trade-off | Potential for plasma-induced damage vs. thermal CVD's high purity. |

Ready to enhance your thin film deposition process? KINTEK specializes in advanced lab equipment, including PECVD systems, to help you achieve high deposition rates on heat-sensitive substrates like polymers and pre-processed electronics. Our expertise ensures you get the right solution for your specific material and throughput needs. Contact our experts today to discuss how we can optimize your laboratory's capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is DLC coating used for? Boost Component Performance with Extreme Hardness & Low Friction

- What temperature is PECVD silicon nitride? A Guide to Low-Temp Deposition for Sensitive Devices

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- Why is a high vacuum system essential for PECVD DLC coatings? Ensure Film Purity and Structural Density

- What temperature is PECVD nitride? Optimize Your Silicon Nitride Film Properties

- What are the technical advantages of using PECVD for nitrogen-doped cobalt catalysts? Enhance OER Reaction Kinetics

- What is the HDP deposition process? Achieve Void-Free Thin Films for Complex Microstructures