Despite its promotion as a high-tech recycling solution, plastic pyrolysis is fundamentally unsustainable due to its significant environmental drawbacks. The process often generates toxic byproducts, has a high carbon footprint, produces low-quality fuel that requires energy-intensive refining, and fails to create a closed-loop system, ultimately perpetuating the production of single-use plastics.

While theoretically capable of converting waste to energy, plastic pyrolysis in practice functions more like a complex and inefficient form of incineration. It struggles with real-world contamination, releases hazardous substances, and undermines the development of truly circular solutions for plastic waste.

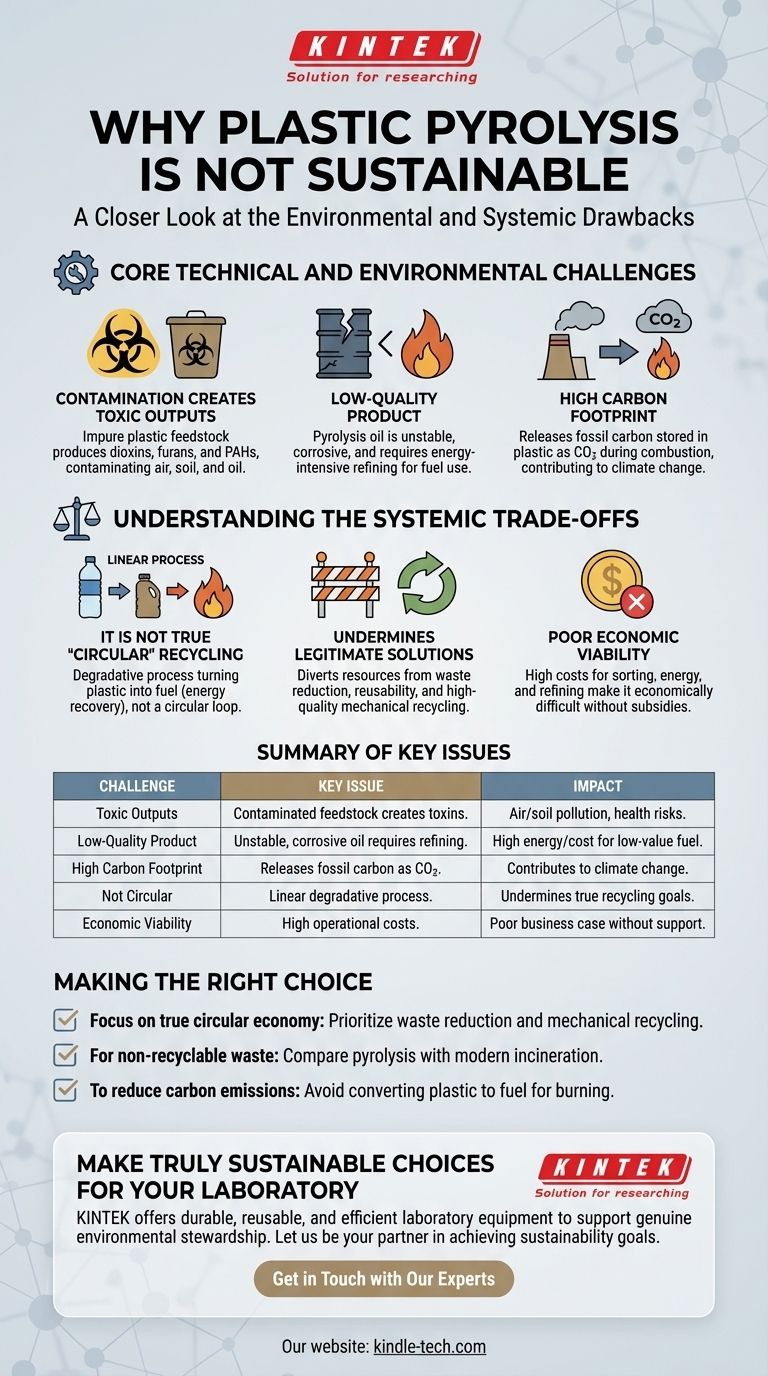

The Core Technical and Environmental Challenges

To understand why pyrolysis falls short, we must look past the idealized concept and examine its real-world application. The challenges are rooted in the very nature of plastic waste and the thermal decomposition process itself.

Contamination Creates Toxic Outputs

Real-world plastic waste is not a clean, uniform feedstock. It is a messy mix of different polymer types, food residue, labels, adhesives, and chemical additives like flame retardants and plasticizers.

When this contaminated mix is heated, these additives and impurities react to form highly toxic byproducts. These include dioxins, furans, and polycyclic aromatic hydrocarbons (PAHs), which can contaminate the resulting oil, solid char, and air emissions.

The Final Product is Not a Clean Fuel

The primary liquid output, pyrolysis oil, is often marketed as a synthetic crude oil. However, it is a low-quality, corrosive, and unstable substance.

It contains high levels of chlorine, heavy metals (like lead and cadmium from pigments), and other contaminants from the original plastic waste. To be used as a fuel or chemical feedstock, it requires significant, energy-intensive pre-treatment and refining, which adds to the overall cost and environmental impact.

The Carbon Footprint Remains High

The process is often touted as energy-efficient, as the gas produced can be burned to power the system. However, this ignores the bigger picture of its climate impact.

Plastic is a fossil fuel product. Pyrolysis effectively takes the carbon locked inside the plastic and, through the final combustion of its fuel products, releases it into the atmosphere as CO2. It is not a carbon-neutral process; it is a delay in the emission of fossil-derived carbon.

Understanding the Systemic Trade-offs

Beyond the technical hurdles, plastic pyrolysis presents economic and systemic problems that conflict with the goals of a sustainable, circular economy.

It Is Not True "Circular" Recycling

Proponents label pyrolysis as "advanced recycling," but this is misleading. True recycling is a circular process that turns an old product back into a new one of similar quality (e.g., bottle-to-bottle).

Pyrolysis is a linear, degradative process. It is a one-way street from plastic to a lower-value fuel that is burned and gone forever. This is more accurately defined as a form of energy recovery, not recycling.

It Undermines Legitimate Solutions

Focusing investment and policy on pyrolysis diverts resources from proven, more sustainable solutions. It actively disincentivizes the crucial goals of reducing plastic production, designing for reusability, and improving mechanical recycling systems.

By creating a perceived "end-of-life solution," pyrolysis provides cover for a business-as-usual approach, allowing companies to continue producing problematic and single-use plastics without fundamentally changing their models.

Poor Economic Viability

The real-world costs of running a pyrolysis plant are often prohibitively high. The extensive sorting required for the plastic feedstock, the energy needed to run the process, and the intensive refining of the final oil make it a difficult business case without substantial public subsidies.

Making the Right Choice for Your Goal

When evaluating pyrolysis, it is critical to align the technology with a clear objective.

- If your primary focus is creating a true circular economy: Prioritize waste reduction, product reuse, and expanding high-quality mechanical recycling, as these methods preserve material value.

- If your primary focus is managing non-recyclable plastic waste: Recognize that pyrolysis is a form of energy recovery with a significant environmental footprint, and its impacts must be compared directly to modern, well-regulated incineration facilities.

- If your primary focus is reducing carbon emissions: Acknowledge that converting plastic into fuel to be burned is a carbon-intensive pathway that contributes to climate change.

Ultimately, achieving sustainability requires addressing the root cause of the plastic crisis—overproduction—rather than searching for complex end-of-pipe fixes.

Summary Table:

| Challenge | Key Issue | Impact |

|---|---|---|

| Toxic Outputs | Contaminated feedstock creates dioxins, furans, and PAHs. | Air/soil pollution and health risks. |

| Low-Quality Product | Pyrolysis oil is unstable, corrosive, and requires refining. | High energy/cost for low-value fuel. |

| High Carbon Footprint | Releases fossil carbon as CO2 from plastic-derived fuel. | Contributes to climate change. |

| Not Circular | Degrades plastic into fuel for burning (linear process). | Undermines true recycling goals. |

| Economic Viability | High costs for sorting, energy, and refining; needs subsidies. | Poor business case without public support. |

Make Truly Sustainable Choices for Your Laboratory

While plastic pyrolysis presents significant sustainability challenges, KINTEK is committed to providing laboratory equipment and consumables that support genuine environmental stewardship. Our products are designed for durability, reusability, and efficiency, helping you reduce waste and energy consumption in your research and testing processes.

Let KINTEK be your partner in achieving your sustainability goals. We specialize in high-quality lab equipment that minimizes environmental impact without compromising performance.

Contact us today to discuss how our solutions can help your laboratory operate more sustainably and effectively.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

People Also Ask

- What is the significance of anhydrous calcium chloride in ferrotitanium production? Optimize Solid-State Reduction

- What is flash sintering? Achieve Rapid, Energy-Efficient Ceramic Densification

- How do you increase filter press efficiency? Optimize Your Dewatering System for Maximum Output

- Why is a laboratory vacuum drying oven or a high-vacuum manifold essential for recovered monomers and catalysts?

- Is pyrolysis renewable? The answer lies in the feedstock you use.

- Which is better carbon or graphite? Choose the Right Material for Your Application

- What role do thermostatic shakers and Erlenmeyer flasks play in bioconversion? Optimize Your Xylose to Xylitol Process

- What is the effect of density on sintering? Achieve Superior Quality and Dimensional Accuracy