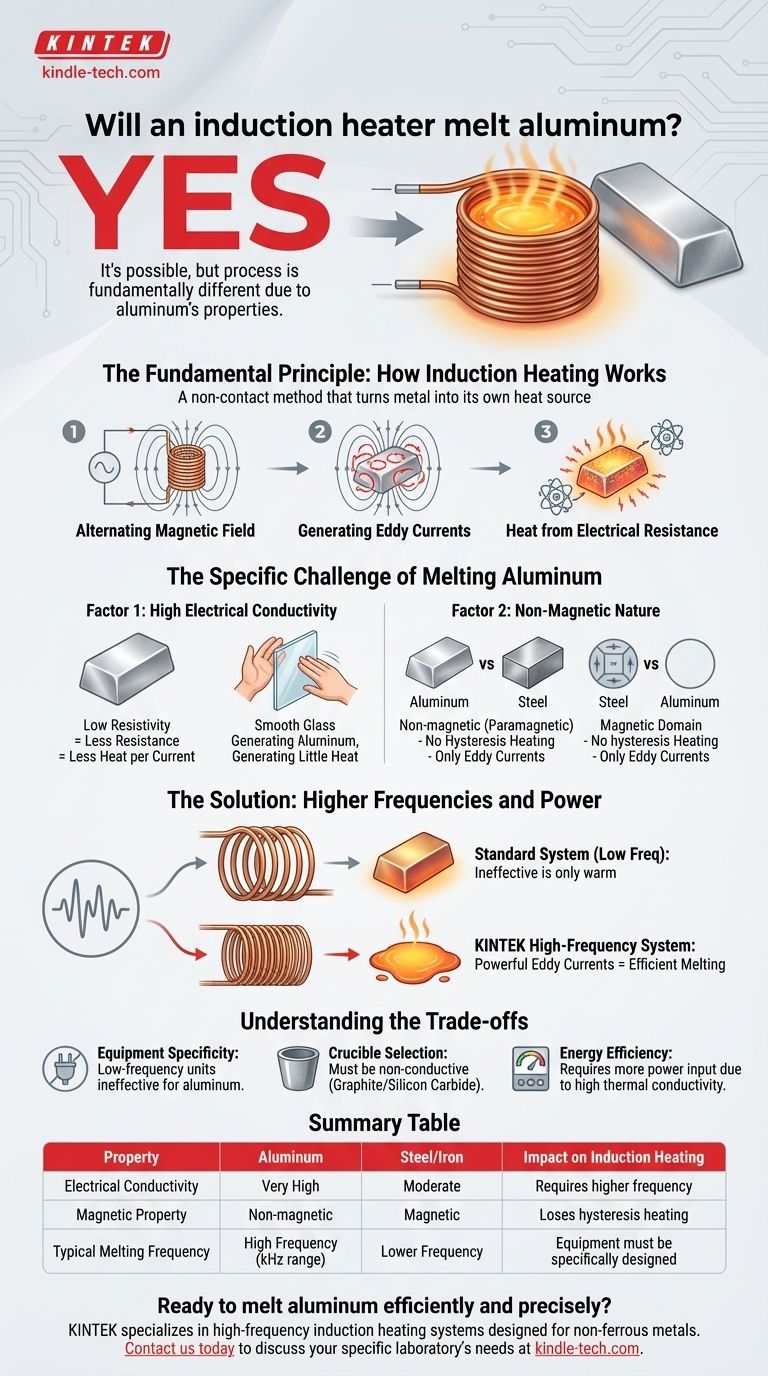

Yes, an induction heater will absolutely melt aluminum. However, the process is fundamentally different from melting iron or steel due to aluminum's unique electrical and magnetic properties. Successfully melting aluminum requires an induction system specifically designed to overcome these properties.

The core challenge isn't whether induction can melt aluminum, but rather having the right equipment to do so efficiently. Aluminum's high conductivity and non-magnetic nature demand an induction heater capable of operating at a higher frequency and power level than what is typically required for steel.

The Fundamental Principle: How Induction Heating Works

To understand the specific requirements for aluminum, we must first review the core mechanism of induction heating. It is a non-contact method that turns the metal workpiece into its own heat source.

The Alternating Magnetic Field

An induction system uses a copper coil through which a high-frequency alternating current (AC) is passed. This creates a powerful and rapidly changing magnetic field around the coil.

Generating Eddy Currents

When a conductive material like aluminum is placed within this magnetic field, the field induces circular electrical currents inside the metal itself. These are known as eddy currents.

Heat from Electrical Resistance

These eddy currents flow against the inherent electrical resistivity of the metal. This opposition generates friction on an atomic scale, producing intense and localized heat that ultimately causes the metal to melt.

The Specific Challenge of Melting Aluminum

While the principle is the same for all metals, aluminum presents two specific properties that make it more challenging to heat than ferrous metals like steel.

Factor 1: High Electrical Conductivity

Aluminum is an excellent electrical conductor, which means it has very low resistivity. According to the heating principle, less resistance means less heat is generated for a given amount of eddy current flow.

Think of it like rubbing two pieces of sandpaper together versus rubbing two sheets of glass. The high friction (high resistance) of the sandpaper creates heat quickly, while the smooth glass (low resistance) generates very little.

Factor 2: Non-Magnetic Nature

Ferrous metals like iron and steel gain an extra heating advantage from a process called hysteresis heating. Their magnetic domains rapidly resist and realign with the changing magnetic field, generating additional internal friction and heat.

Aluminum is a non-magnetic (paramagnetic) material. It does not experience this secondary hysteresis effect, meaning all of its heating must come exclusively from eddy currents.

The Solution: Higher Frequencies and Power

To overcome aluminum's low resistivity, the induction system must induce much stronger eddy currents. This is achieved by increasing the frequency of the alternating current in the coil.

A higher frequency creates a more rapidly changing magnetic field, which in turn generates the powerful eddy currents needed to compensate for the low resistance and melt the aluminum effectively. This typically requires a more specialized and powerful induction power supply.

Understanding the Trade-offs

Choosing induction heating for aluminum involves specific considerations that differ from those for other metals.

Equipment Specificity

A low-frequency induction heater designed for melting large steel components may be completely ineffective for melting aluminum. The equipment's operating frequency range is the single most critical factor for success.

Crucible Selection

The container, or crucible, holding the aluminum must be made of a non-conductive, high-temperature refractory material like graphite or silicon carbide. Using a conductive crucible would cause it to heat up along with, or instead of, the aluminum itself.

Energy Efficiency

While induction is generally efficient, melting aluminum can require more power input compared to steel to reach its melting point (approx. 660°C or 1220°F) due to the need for higher frequencies and the metal's high thermal conductivity, which causes it to lose heat to the environment quickly.

Making the Right Choice for Your Goal

The suitability of induction heating depends entirely on matching the equipment to the unique properties of aluminum.

- If your primary focus is rapid, clean melting for casting: Induction is an excellent choice, provided you invest in a modern, high-frequency system specifically designed for non-ferrous metals.

- If you are a hobbyist with a general-purpose induction heater: You will likely struggle to reach aluminum's melting point unless your unit is specifically rated for high-frequency operation.

- If you are operating a foundry with diverse needs: A coreless induction furnace with variable frequency control offers the greatest flexibility to efficiently process both ferrous metals and non-ferrous alloys like aluminum.

Understanding these principles ensures you can effectively harness induction technology for any conductive material, including aluminum.

Summary Table:

| Property | Aluminum | Steel/Iron | Impact on Induction Heating |

|---|---|---|---|

| Electrical Conductivity | Very High | Moderate | Requires higher frequency to generate sufficient heat |

| Magnetic Property | Non-magnetic | Magnetic | Loses hysteresis heating; relies solely on eddy currents |

| Typical Melting Frequency | High Frequency (kHz range) | Lower Frequency | Equipment must be specifically designed for aluminum |

Ready to melt aluminum efficiently and precisely? KINTEK specializes in high-frequency induction heating systems designed specifically for non-ferrous metals like aluminum. Our expert team will help you select the right equipment to maximize your melting efficiency and achieve superior results. Contact us today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision