Yes, a CVD diamond will pass a standard handheld diamond tester. These testers are designed to measure a material's thermal conductivity—how quickly it moves heat. Because lab-grown CVD diamonds are physically and chemically identical to natural diamonds, they conduct heat in the exact same way and will therefore register as a "diamond."

A basic diamond tester confirms that a stone is, in fact, a diamond. It cannot, however, distinguish a lab-grown diamond from a natural one. Differentiating between them requires specialized laboratory equipment that can detect subtle differences in their atomic growth structure.

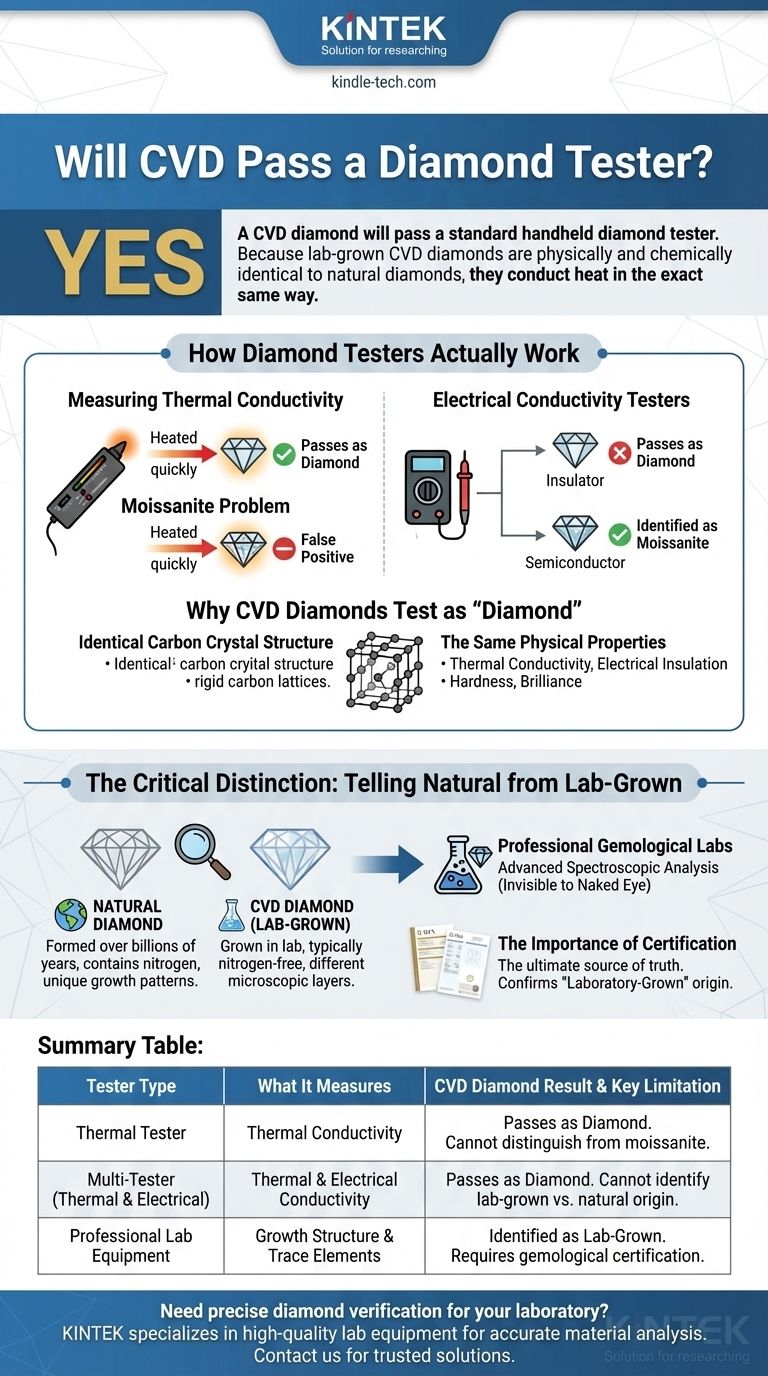

How Diamond Testers Actually Work

To understand why a CVD diamond passes, you must first understand what these common handheld devices are actually measuring. They are not "diamond detectors" but rather property-measuring tools.

Measuring Thermal Conductivity

Most common and affordable diamond testers are thermal probes. They feature a small, heated metal tip that you press against the gemstone.

The device then measures how quickly the heat is pulled away from the tip. Diamond is one of the most thermally conductive materials on earth, so it draws heat away exceptionally fast, causing the tester to indicate "diamond."

The Moissanite Problem

The main challenge for basic thermal testers is moissanite, a common diamond simulant. Moissanite is also an excellent thermal conductor, and it can easily fool a thermal-only tester into giving a false positive for diamond.

Electrical Conductivity Testers

To solve the moissanite issue, more advanced multi-testers were developed. These devices test for both thermal and electrical conductivity.

Diamond is an electrical insulator, while moissanite is a semiconductor. A multi-tester that detects electrical conductivity will correctly identify moissanite and separate it from a diamond. However, a CVD diamond will still pass this test as a diamond because it is also an electrical insulator.

Why CVD Diamonds Test as "Diamond"

A CVD (Chemical Vapor Deposition) diamond is not a "fake" diamond or a simulant like cubic zirconia. It is a diamond that has been grown in a controlled laboratory environment rather than mined from the earth.

Identical Carbon Crystal Structure

Both natural and CVD diamonds are composed of pure carbon atoms arranged in the same rigid crystal lattice structure. This structure is what gives a diamond its hardness, brilliance, and unique physical properties.

The Same Physical Properties

Because the atomic makeup and crystal structure are identical, the resulting physical properties—including thermal and electrical conductivity—are also identical. A tester designed to identify these properties cannot tell the difference because, at that level, there is no difference to find.

The Critical Distinction: Telling Natural from Lab-Grown

While a handheld tester can confirm you have a diamond, it cannot tell you its origin. That requires a gemological laboratory with highly specialized instruments.

The Role of Gemological Labs

Professional labs like the Gemological Institute of America (GIA) or the International Gemological Institute (IGI) use sophisticated equipment to definitively determine a diamond's origin.

Detecting Growth Patterns and Impurities

Lab instruments analyze the diamond's internal growth structure and trace element composition. Natural diamonds contain minute amounts of nitrogen and exhibit specific growth patterns formed over billions of years under the earth.

CVD diamonds, grown in layers, have a different microscopic growth structure and are typically free of nitrogen. Advanced spectroscopic analysis can detect these subtle markers, which are invisible to the naked eye and undetectable by handheld testers.

The Importance of Certification

This is why a reputable certificate is the ultimate source of truth. A grading report from a major lab will explicitly state if the diamond is "Laboratory-Grown" and often specifies the growth method (CVD or HPHT). This disclosure provides complete transparency about the stone's origin.

Understanding the Trade-offs

Relying on a simple tester provides an incomplete picture. Understanding its limitations is key to making an informed decision.

Tester Limitations

A handheld tester is a useful tool for screening out obvious simulants like glass or cubic zirconia. However, it cannot be your final authority for determining value or origin.

The Value Proposition

CVD diamonds offer an affordable alternative to natural diamonds, providing the same physical beauty and durability. The trade-off is in its origin and long-term resale value, which typically differs from that of a natural diamond.

Post-Growth Treatments

As some certificates note, CVD diamonds may undergo post-growth treatments to enhance their color. This is a standard practice and another piece of information that only a full lab report can provide, reinforcing the need for transparent certification over simple testing.

Making the Right Choice for Your Goal

Your verification method should align with the information you need to find.

- If your primary focus is quick verification: A standard diamond tester will correctly confirm a CVD stone is a diamond, separating it from non-diamond simulants.

- If your primary focus is differentiating from moissanite: A multi-tester that measures both thermal and electrical conductivity is the necessary tool.

- If your primary focus is determining origin (Natural vs. Lab-Grown): You must rely on a professional gemological certificate, as no handheld tester can make this distinction.

Understanding these distinctions empowers you to purchase with confidence, knowing precisely the nature and origin of your stone.

Summary Table:

| Tester Type | What It Measures | CVD Diamond Result | Key Limitation |

|---|---|---|---|

| Thermal Tester | Thermal Conductivity | Passes as Diamond | Cannot distinguish from moissanite |

| Multi-Tester (Thermal & Electrical) | Thermal & Electrical Conductivity | Passes as Diamond | Cannot identify lab-grown vs. natural origin |

| Professional Lab Equipment | Growth Structure & Trace Elements | Identified as Lab-Grown | Requires gemological certification |

Need precise diamond verification for your laboratory? At KINTEK, we specialize in high-quality lab equipment and consumables tailored for accurate material analysis. Whether you're testing gemstones, conducting research, or ensuring quality control, our tools provide the reliability and precision you need. Contact us today to discover how KINTEK can support your laboratory's specific requirements with trusted solutions.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Wire Drawing Die Blanks for Precision Applications

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- Why is a water bath used in evaporation? Achieve Safe, Gentle Heating for Your Lab

- What are the potential risks of storing samples at -70C instead of -80C? Optimize Your Lab's Reliability & Costs

- What are the disadvantages of wiped film molecular still? High Cost, Complexity & Separation Limits

- How are Ultra Freezers designed for easy movement in laboratories? Unlock Lab Flexibility with Swivel Castors

- What is a major advantage of pyrolysis in converting biomass to energy? It Creates Transportable Liquid Fuel

- Why sputter coating is used for specimen preparation? Prevent Charging for Clear SEM Imaging

- What refrigerants are used in ULT freezers and why? Modern Units Use Eco-Friendly Hydrocarbons

- What is the main source of biochar? Unlock the Power of Sustainable Feedstocks