Traditional Chemical Methods in PV Module Recycling

Use of Toxic Organic Solvents

Historically, researchers have relied on toxic organic solvents such as toluene and trichloroethylene for the dissolution of EVA adhesive film in photovoltaic (PV) module recycling. These solvents, while effective in breaking down the adhesive, come with significant drawbacks. Firstly, they pose substantial health risks to those handling them, necessitating stringent safety measures and protective equipment. Secondly, the dissolution process using these solvents is often time-consuming, leading to extended processing times and increased operational costs.

The use of toluene and trichloroethylene is not only hazardous to human health but also detrimental to the environment. These solvents are known to have long-term environmental impacts, contributing to soil and water contamination. Moreover, their disposal is complex and requires specialized treatment to mitigate environmental harm, adding another layer of complexity and expense to the recycling process.

In summary, while traditional toxic organic solvents like toluene and trichloroethylene have been instrumental in the dissolution of EVA adhesive film, their health and environmental risks, coupled with their slow dissolution times, underscore the urgent need for more sustainable alternatives in the field of PV module recycling.

Challenges in Separation and Purification

The cross-linking of EVA (ethylene-vinyl acetate) surface presents a significant challenge in the separation and purification of photovoltaic (PV) cells and EVA film using traditional mechanical methods. This cross-linking phenomenon, which occurs during the manufacturing process, creates a robust bond that resists mechanical disintegration. As a result, conventional techniques such as physical grinding or shredding prove ineffective in achieving the necessary separation, leading to compromised efficiency and purity in the recovered materials.

Moreover, the mechanical methods employed often result in the degradation of PV cells, further complicating the recycling process. The inability to effectively separate the EVA film from the PV cells not only hampers the recycling efficiency but also raises concerns about the quality and performance of the recovered materials. This issue underscores the need for more advanced, non-mechanical approaches to overcome the limitations imposed by the cross-linked EVA surface.

In light of these challenges, the development of alternative methods, particularly those involving green solvents, has gained traction. These environmentally friendly solvents offer a promising solution by facilitating the dissolution of EVA without the drawbacks associated with traditional toxic organic solvents. The shift towards green solvents, such as Deep Eutectic Solvents (DES), is thus seen as a critical step in enhancing the sustainability and effectiveness of PV module recycling processes.

Development of Green Solvents

Introduction of Environmentally Friendly Solvents

In recent years, the photovoltaic industry has witnessed a significant shift towards more sustainable practices, particularly in the realm of solvent usage. As early as 2022, researchers initiated the development of a new generation of green solvents designed to mitigate the environmental and health impacts associated with traditional chemical methods. These innovative solvents, including DMPU (1,3-Dimethyl-2-imidazolidinone), EGDA (Ethylene Glycol Diacetate), DBE (Dibasic Esters), Cinene (a type of terpene), and Deep Eutectic Solvents (DES), have emerged as promising alternatives due to their reduced toxicity and enhanced environmental compatibility.

The transition to these green solvents is not merely a response to regulatory pressures but a strategic move towards more sustainable industrial practices. These solvents offer several advantages, such as lower health risks for workers, reduced environmental contamination, and improved efficiency in processes like photovoltaic module recycling. For instance, DES, a class of solvents formed by the combination of hydrogen bond donors and acceptors, have been particularly highlighted for their unique properties, including low toxicity, biocompatibility, and biodegradability.

The development of these green solvents represents a critical step in the evolution of photovoltaic recycling technologies, aligning with global efforts to reduce the carbon footprint of industrial operations. By opting for these environmentally friendly alternatives, the industry not only enhances its sustainability profile but also paves the way for more efficient and eco-conscious recycling processes.

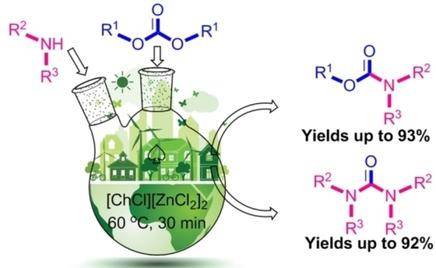

Advantages of Deep Eutectic Solvents (DES)

Deep eutectic solvents (DES) have emerged as a promising alternative in the field of photovoltaic (PV) module recycling due to their unique properties. Unlike traditional toxic organic solvents, DES offer a range of benefits that make them highly suitable for environmentally friendly recycling processes.

Firstly, DES are characterized by their low toxicity. This significantly reduces the health risks associated with their handling and use, making the recycling process safer for workers and the environment. The biocompatibility of DES further enhances their appeal, as they can be used in processes that require minimal disruption to biological systems.

In addition to their low toxicity and biocompatibility, DES are also biodegradable. This means that they break down naturally in the environment, reducing the risk of long-term ecological damage. This property is particularly important in the context of PV module recycling, where the goal is to minimize the environmental impact of the recycling process.

Another key advantage of DES is their ease of preparation. Unlike many traditional solvents, which require complex and energy-intensive manufacturing processes, DES can be easily synthesized from readily available, inexpensive starting materials. This not only reduces the cost of production but also simplifies the supply chain, making DES a more accessible and practical option for industrial applications.

The combination of these properties—low toxicity, biocompatibility, biodegradability, and ease of preparation—positions DES as a highly promising candidate for the future of PV module recycling. By leveraging the unique advantages of DES, researchers and industry professionals can develop more sustainable and efficient recycling processes, ultimately contributing to the broader goal of a circular economy in the renewable energy sector.

Chemical Phenomenon of Eutectic Systems

Formation and Properties of Eutectic Systems

Eutectic systems arise when two or more compounds solidify simultaneously in a precise ratio, resulting in mixtures that exhibit distinctive structural and property profiles. This phenomenon is characterized by the formation of a unique solid solution where the individual components crystallize together, rather than separately. The eutectic point represents the lowest melting temperature for the given mixture, which is lower than the melting points of the individual components.

The structural properties of eutectic systems are highly dependent on the nature of the compounds involved. For instance, the resulting microstructure can range from lamellar to rod-like, depending on factors such as the composition ratio and the interaction forces between the compounds. These microstructures play a crucial role in determining the mechanical, thermal, and electrical properties of the eutectic mixture.

Moreover, eutectic systems often exhibit superior properties when compared to the individual components. For example, they can offer enhanced thermal stability, better mechanical strength, and improved electrical conductivity. These advantages make eutectic systems particularly attractive in various industrial applications, including the development of green solvents for photovoltaic (PV) module recycling, as highlighted in the shift towards deep eutectic solvents (DES).

In the context of PV module recycling, DES, which are a type of eutectic system, are gaining prominence due to their low toxicity, biocompatibility, biodegradability, and ease of preparation. These properties not only align with the sustainability goals of the recycling process but also offer practical advantages in terms of handling and environmental impact.

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Evaporation Crucible for Organic Matter

- Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

Related Articles

- Revolutionize Your Spectroscopy Analysis with FTIR Pellet Press

- 5 Essential Applications of Rotary Evaporator in Labs

- Glassware vs. Plasticware - Which is the Better Choice for Your Needs?

- How FTIR Pellet Press Works in Sample Preparation for Spectroscopy Analysis

- How To Clean Laboratory Glassware - Part 2