Introduction to Target Poisoning

Definition and Characteristics

Target poisoning in magnetron sputtering refers to the process where the target material, typically a metal or alloy, interacts with reactive gases such as oxygen or nitrogen during the sputtering process. This interaction results in the formation of insoluble compounds, primarily oxides or nitrides, which adhere to the target surface. These compounds significantly diminish the effective sputtering area, thereby disrupting the deposition process.

The consequences of target poisoning are multifaceted. Firstly, it leads to a marked reduction in the sputtering rate, which directly impacts the efficiency of the deposition process. Secondly, the quality of the deposited film is compromised, as the presence of these insoluble compounds can introduce impurities and defects. Lastly, target poisoning accelerates the depletion of the target material, necessitating more frequent replacements and increasing operational costs.

To illustrate, consider a scenario where a titanium target is used in the presence of oxygen. The titanium reacts with the oxygen, forming titanium oxide (TiO₂) on the target surface. This oxide layer is not only non-conductive but also resistant to further sputtering, effectively reducing the active area of the target. As a result, the sputtering rate decreases, and the quality of the deposited film deteriorates, often exhibiting uneven thickness and reduced adhesion.

In summary, target poisoning is a critical issue in magnetron sputtering that necessitates careful monitoring and mitigation strategies to ensure optimal deposition outcomes.

Effects on Deposition Process

Target poisoning significantly impacts the deposition process in several critical ways. Firstly, it directly influences the deposition rate. As the target material forms insoluble compounds with gases like oxygen or nitrogen, the effective sputtering area decreases, leading to a slower deposition rate. This reduction in rate can elongate production cycles, thereby reducing overall efficiency.

Secondly, the composition of the deposited film is compromised. The presence of these insoluble compounds can introduce impurities into the film, altering its intended properties. For instance, the film may exhibit reduced conductivity, altered mechanical properties, or increased fragility, all of which can undermine the functionality of the final product.

Moreover, target poisoning affects the stability of the equipment used in the deposition process. The formation of compounds on the target surface can lead to uneven sputtering, causing mechanical stress and potential damage to the equipment. This instability necessitates more frequent maintenance and repairs, thereby increasing operational costs.

In summary, target poisoning results in reduced production efficiency, compromised film properties, and elevated maintenance costs. These effects underscore the importance of understanding and mitigating target poisoning to ensure the quality and economic viability of the deposition process.

Causes of Target Poisoning

Gas Reaction

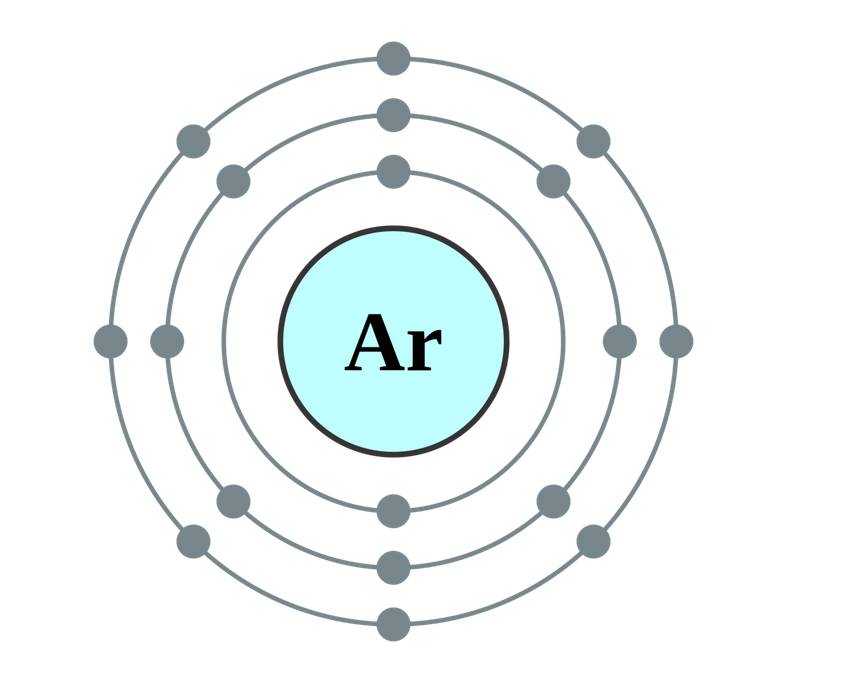

The interaction between the target material and working gases such as argon, nitrogen, and oxygen is a critical factor in the phenomenon of target poisoning. During the sputtering process, these gases can react with the target material, leading to the formation of compounds that contaminate the target surface. This contamination significantly impacts the efficiency and effectiveness of the sputtering process.

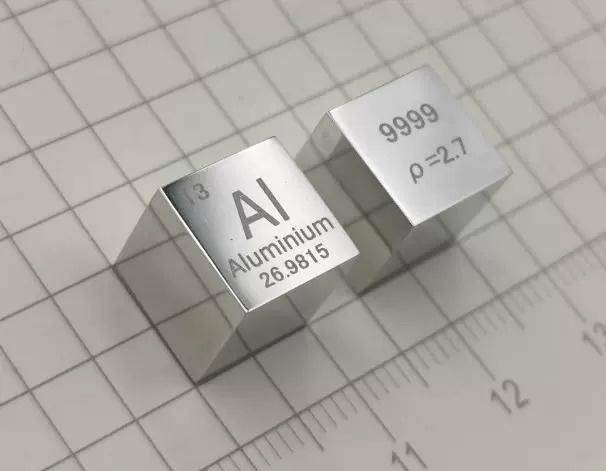

The primary gases involved in these reactions are oxygen and nitrogen, which are known to form stable compounds with many target materials. For instance, metals like aluminum and magnesium are particularly susceptible to forming oxides and nitrides, which are insoluble and adhere to the target surface. These compounds not only reduce the effective sputtering area but also alter the composition of the deposited film, affecting its properties and performance.

Moreover, the presence of these reactive gases can lead to the formation of complex chemical species that further exacerbate the contamination. For example, the reaction of oxygen with titanium can result in the formation of titanium oxides, which are hard and resistant to sputtering. This makes it difficult to remove these compounds from the target surface, thereby prolonging the contamination and reducing the overall sputtering rate.

In summary, the gas reaction component of target poisoning is a multifaceted issue that involves the interaction of target materials with reactive gases, leading to the formation of compounds that contaminate the target surface and degrade the sputtering process. Understanding these reactions is crucial for developing effective preventive measures and maintaining the quality of the deposition process.

Sputtering Molecular Redeposition

During the magnetron sputtering process, reactants or intermediates from the target material can redeposit onto the target surface, leading to the formation of insoluble compounds. This phenomenon, known as sputtering molecular redeposition, plays a significant role in the overall target poisoning process. The redeposited materials often include reactive species such as oxides, nitrides, or carbides, which can significantly alter the surface chemistry and morphology of the target.

The formation of these insoluble compounds can be attributed to several factors, including the chemical reactivity of the target material with the surrounding gases, the energy distribution of the sputtered particles, and the local environment within the sputtering chamber. For instance, metals like aluminum and magnesium are particularly susceptible to forming stable oxides or nitrides upon redeposition, which can exacerbate the poisoning effect.

The redeposition process can be visualized as follows: as the target material is sputtered, some of the ejected particles react with the ambient gases before reaching the substrate. These reacted particles then return to the target surface, where they form a layer of insoluble compounds. Over time, this layer can grow, reducing the effective sputtering area and leading to a decrease in the sputtering rate and film quality.

To mitigate the effects of sputtering molecular redeposition, various preventive measures can be employed. These include optimizing the sputtering parameters, controlling the gas composition, and selecting target materials with lower reactivity. Additionally, regular cleaning and maintenance of the target surface can help restore its effective utilization and reduce the buildup of insoluble compounds.

Temperature and Power Effects

High temperatures or excessive power can significantly exacerbate target reactions during magnetron sputtering, leading to the formation of more compounds. This intensification of reactions can be attributed to several factors:

-

Thermal Activation: Elevated temperatures can increase the kinetic energy of molecules and atoms, making them more likely to undergo reactions with surrounding gases. This thermal activation can accelerate the formation of insoluble compounds on the target surface.

-

Power Density: Excessive power applied during sputtering can lead to localized heating, causing a concentration of reactive species at specific points on the target. This can result in the rapid formation of compounds, particularly oxides or nitrides, which are more stable at higher temperatures.

-

Increased Ionization: Higher power levels can increase the ionization of sputtering gases, leading to a higher concentration of reactive ions bombarding the target. These ions can induce more chemical reactions, further contributing to compound formation.

The table below summarizes the effects of temperature and power on target reactions:

| Factor | Effect on Reactions |

|---|---|

| Temperature | Increases kinetic energy, promoting more frequent and vigorous chemical reactions. |

| Power Density | Causes localized heating, concentrating reactive species and accelerating reactions. |

| Increased Ionization | Enhances the concentration of reactive ions, inducing more chemical reactions. |

These effects collectively contribute to the increased formation of compounds, which can lead to target poisoning, reducing the efficiency and quality of the sputtering process.

Target Material Properties

Certain target materials, such as aluminum and magnesium, exhibit a higher propensity for forming stable oxides or nitrides, which significantly exacerbates the issue of target poisoning. This is due to their inherent chemical reactivity with gases like oxygen and nitrogen, leading to the formation of insoluble compounds that accumulate on the target surface. These compounds not only reduce the effective sputtering area but also alter the composition and quality of the deposited films.

To illustrate, aluminum, known for its strong affinity for oxygen, readily forms aluminum oxide (Al₂O₃) during sputtering. Similarly, magnesium reacts with nitrogen to form magnesium nitride (Mg₃N₂). These stable compounds are difficult to remove and can persist throughout the sputtering process, leading to continuous degradation of the target's performance. The table below highlights the common oxides and nitrides formed by these materials and their implications on sputtering efficiency.

| Target Material | Compound Formed | Impact on Sputtering |

|---|---|---|

| Aluminum | Al₂O₃ | Reduces sputtering rate and film quality |

| Magnesium | Mg₃N₂ | Increases target loss and affects deposition process |

The formation of these compounds is not only detrimental to the sputtering process but also necessitates more frequent maintenance and cleaning of the target, thereby increasing operational costs. Therefore, understanding the chemical properties of target materials and their reactivity with common gases is crucial for mitigating the effects of target poisoning.

Preventive Measures

Control Gas Composition

To mitigate the risk of target poisoning in magnetron sputtering, it is crucial to carefully manage the composition of the gases within the sputtering chamber. The primary objective is to minimize the presence of reactive gases, such as oxygen and nitrogen, which can react with the target material to form insoluble compounds. These compounds not only contaminate the target surface but also reduce the effective sputtering area, thereby degrading the quality of the deposited film.

One effective strategy is to utilize inert gases, such as argon, which are less likely to react with the target material. Argon, in particular, is widely used due to its inert properties and the fact that it does not form stable compounds with most target materials. By replacing reactive gases with argon, the likelihood of target contamination is significantly reduced, thereby preserving the integrity of the sputtering process.

Additionally, maintaining a controlled gas environment can help in optimizing the deposition parameters. For instance, adjusting the flow rate and pressure of the inert gas can further enhance the uniformity and quality of the deposited film. This controlled environment not only aids in preventing target poisoning but also contributes to the overall efficiency and stability of the sputtering equipment.

In summary, controlling the gas composition through the judicious use of inert gases like argon is a vital preventive measure against target poisoning. This approach ensures that the target material remains uncontaminated, thereby maintaining the efficiency and quality of the deposition process.

Regulate Working Temperature

Maintaining an optimal working temperature is crucial in preventing target poisoning during magnetron sputtering. High temperatures can significantly exacerbate the reactions between the target material and gases such as oxygen or nitrogen. These reactions lead to the formation of insoluble compounds that not only contaminate the target surface but also reduce the effective sputtering area. This reduction in sputtering area directly impacts the deposition process, leading to a decrease in sputtering rate, compromised film quality, and increased target loss.

To mitigate these effects, it is essential to operate within a temperature range that minimizes the risk of gas reactions. This involves precise temperature control and, in some cases, the use of cooling systems to maintain a stable and low-temperature environment. By doing so, the likelihood of forming detrimental compounds is significantly reduced, thereby preserving the integrity and efficiency of the sputtering process.

Furthermore, regulating the working temperature also helps in optimizing the overall sputtering parameters. It ensures that the target material remains in a state where its reactivity with gases is minimized, thereby enhancing the consistency and quality of the deposited films. This approach not only improves production efficiency but also reduces the need for frequent maintenance and replacement of the target material.

In summary, controlling the working temperature is a critical preventive measure in magnetron sputtering. It helps in maintaining the target material's integrity, ensuring high-quality film deposition, and prolonging the operational life of the sputtering equipment.

Optimize Sputtering Parameters

Optimizing sputtering parameters is crucial for mitigating the risk of target poisoning, which can significantly degrade the quality and performance of deposited thin films. Key parameters such as air pressure and power levels must be meticulously adjusted to enhance the efficiency of the sputtering process.

One effective strategy is to regulate the target power density, which is the amount of power applied to the target material per unit area. This parameter directly influences the sputtering rate and the quality of the deposited film. The target power density can be calculated using the formula:

[ R_{\text{sputter}} = \left( \frac{\Phi}{2} \right) \times \left( \frac{n}{N_A} \right) \times \left( \frac{A}{d} \right) \times \left( \frac{v}{1 + \frac{v^2}{v_c^2}} \right) \times (1 + \alpha) ]

Where:

- ( \Phi ) is the ion flux density

- ( n ) is the number of target atoms per unit volume

- ( N_A ) is Avogadro's number

- ( A ) is the atomic weight of the target material

- ( d ) is the distance between the target and substrate

- ( v ) is the average velocity of the sputtered atoms

- ( v_c ) is the critical velocity

- ( \alpha ) is the degree of ionization

By fine-tuning these variables, it is possible to achieve a more balanced and efficient sputtering process. For instance, increasing the ion flux density can enhance the sputtering rate, but it must be balanced with other parameters to prevent excessive target erosion. Similarly, adjusting the distance between the target and substrate can influence the deposition uniformity and film quality.

In modern DC magnetron sputter coaters, the use of an annular magnet behind the target helps confine the plasma, creating a highly efficient sputtering environment. However, this design often leads to a "race track" effect, where only a small portion of the target is effectively utilized. To maximize target usage, it is essential to rotate or replace the target periodically, ensuring that different areas of the target are exposed to the plasma.

Moreover, optimizing the power settings can prevent thermal damage and reduce the formation of undesirable compounds on the target surface. By maintaining a high voltage below 1 kV, the sputtering process remains efficient while minimizing the risk of target poisoning.

In summary, optimizing sputtering parameters involves a careful balance of various factors, including target power density, ion flux, and distance between the target and substrate. By implementing these adjustments, it is possible to significantly reduce the risk of target poisoning, thereby enhancing the overall efficiency and quality of the sputtering process.

Regular Cleaning and Maintenance

Regular cleaning and maintenance are crucial steps in preventing and mitigating target poisoning in magnetron sputtering processes. Cleaning the target surface not only restores its effective utilization but also enhances the overall efficiency and longevity of the sputtering system.

To ensure optimal performance, it is essential to establish a systematic cleaning routine. This routine should involve the removal of contaminants such as oxides, nitrides, and other insoluble compounds that accumulate on the target surface over time. These contaminants can significantly reduce the sputtering rate and compromise the quality of the deposited films.

| Cleaning Method | Description | Benefits |

|---|---|---|

| Chemical Cleaning | Use specific solvents or acids to dissolve and remove contaminants. | Effective for removing heavy deposits; restores surface integrity. |

| Mechanical Polishing | Employ abrasive tools to physically remove contaminants. | Ideal for surfaces with hard, adherent deposits; improves surface finish. |

| Electrochemical Cleaning | Apply an electric current to dissociate contaminants from the surface. | Efficient for delicate surfaces; minimizes mechanical damage. |

In addition to cleaning, regular maintenance checks should be conducted to monitor the condition of the sputtering equipment. This includes inspecting for signs of wear, ensuring proper alignment of components, and verifying that all systems are functioning within operational parameters. By combining thorough cleaning with consistent maintenance, you can significantly reduce the risk of target poisoning and prolong the lifespan of your sputtering targets.

Select Suitable Target Material

Selecting the appropriate target material is crucial for mitigating the risk of target poisoning in magnetron sputtering. The choice of target material directly influences the reactivity with gases such as oxygen and nitrogen, which are common in the sputtering environment. Materials with low reactivity are preferred as they are less likely to form stable compounds that can contaminate the target surface.

For instance, materials like titanium and chromium exhibit lower reactivity compared to aluminum and magnesium, which are known to form stable oxides and nitrides. This difference in reactivity can significantly impact the deposition process, affecting the quality and uniformity of the deposited film. By opting for materials with inherently lower reactivity, the formation of insoluble compounds that lead to target poisoning is minimized, thereby enhancing the overall efficiency and longevity of the sputtering process.

In addition to reactivity, the selection should also consider the specific deposition needs, such as the desired film properties and the operating conditions of the sputtering system. A well-chosen target material not only prevents poisoning but also ensures that the deposited films meet the required specifications, reducing the need for frequent maintenance and improving production efficiency.

Pretreatment Processes

Pretreatment processes are essential in preparing magnetron sputtering targets to resist poisoning and enhance their overall performance. One of the most effective methods is annealing, which involves heating the target material to a specific temperature and then slowly cooling it. This process can significantly improve the target's surface properties by reducing internal stresses, enhancing grain structure, and minimizing the formation of harmful compounds.

| Pretreatment Method | Purpose | Benefits |

|---|---|---|

| Annealing | Improves surface properties | Reduces internal stresses, enhances grain structure, minimizes compound formation |

| Surface Polishing | Smooths surface for better adhesion | Enhances film quality, reduces defects |

| Etching | Removes surface contaminants | Improves target purity, reduces poisoning risk |

Annealing, in particular, can lead to a more uniform and stable target surface, which is crucial for maintaining consistent sputtering rates and film properties. By optimizing the target's microstructure, annealing helps in reducing the likelihood of forming oxides or nitrides that can contribute to target poisoning.

In addition to annealing, other pretreatment methods such as surface polishing and etching can further enhance the target's performance. Surface polishing ensures a smoother target surface, which can improve film adhesion and reduce defects. Etching, on the other hand, helps in removing any surface contaminants or oxides that might have formed during storage or handling, thereby reducing the initial risk of poisoning.

These pretreatment processes are not just about improving the target's surface properties; they also play a critical role in extending the target's lifespan and ensuring more reliable deposition outcomes. By implementing these methods, manufacturers can significantly mitigate the risks associated with target poisoning, leading to improved production efficiency and higher-quality films.

Online Monitoring

Implementing real-time monitoring systems is a critical preventive measure against target poisoning in magnetron sputtering processes. These systems continuously track the operational parameters and environmental conditions within the sputtering chamber, providing immediate feedback on any deviations that could lead to poisoning. By integrating sensors and data acquisition tools, operators can detect early signs of target contamination, such as changes in gas composition, temperature fluctuations, or abnormal power consumption.

For instance, monitoring the gas composition in real-time allows for the immediate detection of reactive gases like oxygen or nitrogen that could react with the target material. If such gases are detected, automated systems can adjust the gas flow to minimize their concentration, thereby reducing the risk of compound formation on the target surface. Similarly, temperature sensors can alert operators to any sudden increases in temperature, which could intensify target reactions and accelerate poisoning.

Moreover, real-time monitoring can also track the sputtering rate and film quality, providing insights into how these parameters are affected by potential poisoning. This data can be used to adjust sputtering parameters on-the-fly, ensuring that the deposition process remains efficient and the quality of the deposited film is maintained. In essence, online monitoring acts as an early warning system, enabling proactive measures to be taken before significant damage occurs, thereby preserving the integrity of the target and the quality of the final product.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Vacuum Heat Treat Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace