The Objective of Powder-Based Manufacturing Processes

Table of Contents

- The Objective of Powder-Based Manufacturing Processes

- The Cold Isostatic Pressing (CIP) Process

- The Hot Isostatic Pressing (HIP) Process

- The Opportunity for Single Step Pre-Processing of Constructs via Multi-Material Additive Manufacturing

- The Use of kintek's Selective Deposition Technology in Isostatic Pressing

- The Potential of a Similar Approach for Parts Processed Using HIP

- Conclusion: The Bridge of Selective Powder Deposition between New Additive Manufacturing and Traditional Manufacturing

The aim of most powder-based manufacturing processes

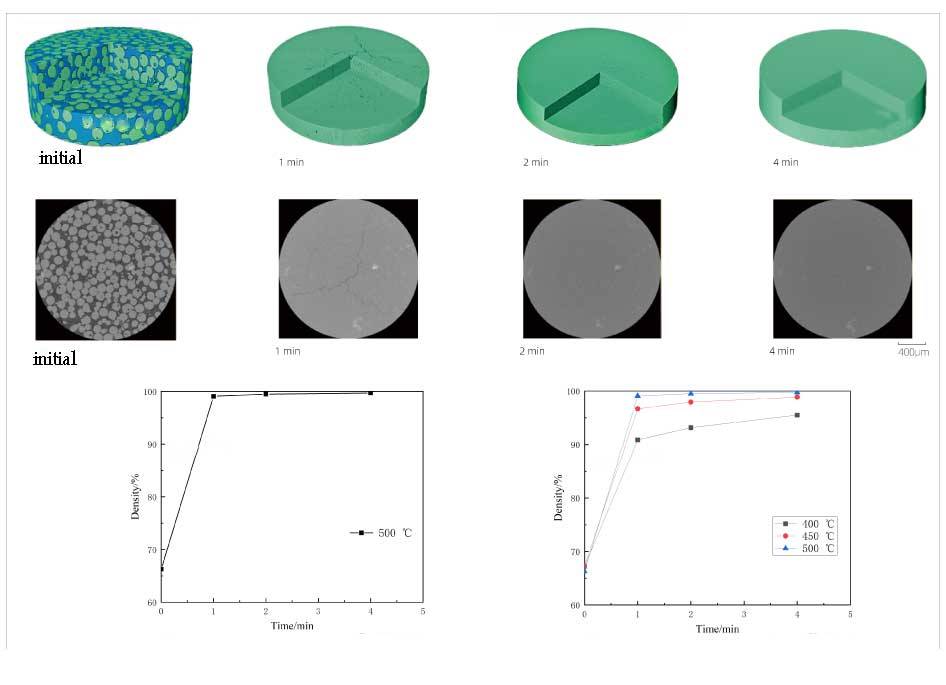

The goal of most powder-based manufacturing processes, such as powder metallurgy (PM), is to produce dense parts with less than 1% porosity without melting the starting material. The loose powder used in these processes typically has a low stacking density, with a theoretical maximum density of only 64% for randomly stacked perfectly spherical particles. However, by using proper powder particle size distributions or deformable powders, packing densities of over 90% can be achieved.

The limitations of uniaxial pressing

To obtain satisfactory results in powder-based manufacturing processes, applying pressure is crucial. Uniaxial pressing, where pressure is applied in one direction, is commonly used. However, this method has limitations, particularly for thick parts. It tends to result in differences in density along the pressing direction, which can affect the quality of the final part.

The solution: isostatic pressing

To overcome the limitations of uniaxial pressing, isostatic pressing is often used for bulk parts. Isostatic pressing is a powder processing technique that uses fluid pressure to compact the part. Metal powders are placed in a flexible container, which serves as the mold for the part. Fluid pressure is exerted over the entire outside surface of the container, causing it to press and form the powder into the desired geometry. Unlike uniaxial pressing, isostatic pressing applies pressure from all directions, resulting in a more uniform density distribution.

Alternative Processes

Isostatic Pressing

Isostatic pressing is a widely used powder-based manufacturing process that applies uniform pressure to consolidate powders or heal defects in castings. It can be used for a range of materials, including ceramics, metals, composites, plastics, and carbon. The process involves placing the powder in a flexible mold, sealing it, and subjecting it to pressure from all directions. Isostatic pressing offers unique benefits for ceramic and refractory applications, as it allows for the formation of product shapes with precise tolerances, reducing the need for costly machining.

Powdered Metal Processing

Powdered metal processing is another powder-based manufacturing technique that allows for the production of products with properties that can surpass alloyed materials. In this process, metal or ceramic powders, along with a binder, are mixed to form a mixture that can be pressed into desired shapes. For larger parts, the mixture is filled into molds. This process is commonly used in the production of products like Polycrystalline Diamond Composite (PDC) drill bits for deep well drilling, where the mixture is pressed and fired to yield near-net shape products.

Advances in Powder Metallurgy

Powder-based processes, such as powder compaction, powder hot-isostatic pressing (P-HIP), metal-injection molding (MIM), and spark plasma sintering, are increasingly used to manufacture net-shape (NS) and near-net-shape (NNS) components of high-performance alloys. These processes aim to fabricate parts that closely match the required final geometry, reducing cost, lead time, and materials waste by minimizing process steps like machining and finishing. Powder-based technologies have the capability to produce parts with performance properties that can match or even improve upon those of traditional manufacturing processes like casting. This is due to factors such as the uniform microstructure associated with particulate materials and the advances in powder metallurgy that allow for a wide range of high-performance alloys to be produced in powder format.

In conclusion, the objective of powder-based manufacturing processes is to produce dense parts with high packing densities and minimal porosity. Isostatic pressing is a valuable technique used to overcome the limitations of uniaxial pressing, providing more uniform density distribution in thick parts. Additionally, alternative processes like powdered metal processing and advances in powder metallurgy have expanded the capabilities of powder-based manufacturing, allowing for the production of complex shapes and high-performance alloys.

The Cold Isostatic Pressing (CIP) Process

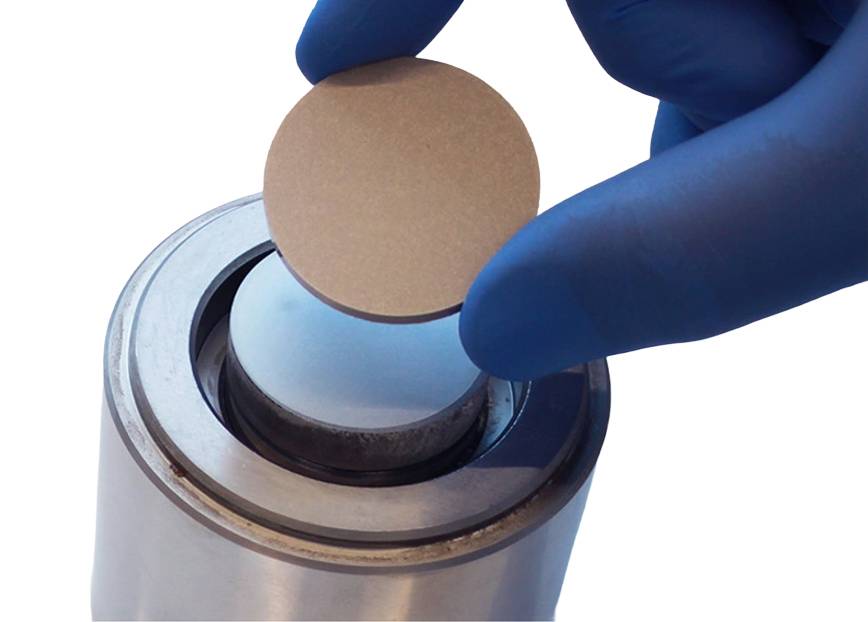

The process of CIP

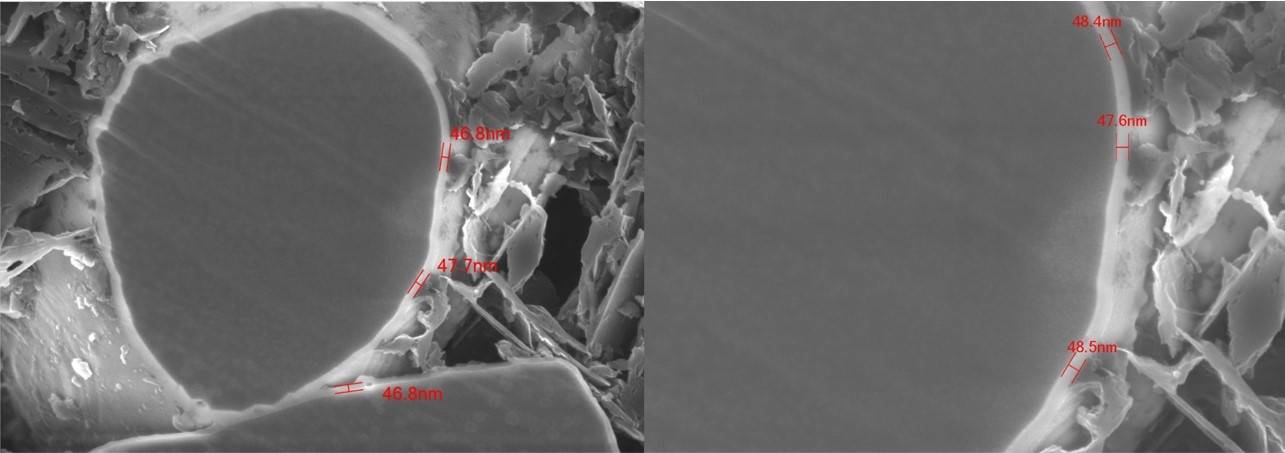

Cold Isostatic Pressing (CIP) is a material processing method used to shape and compact powders into components of varying sizes and shapes. It involves placing the powder or a low-density green part in a sealed flexible container and submerging it in liquid within a pressure vessel. A pressure of several thousand bar is applied, compressing the green compact as close to its maximum packing density as possible. This higher initial density speeds up consolidation to the final density in the thermal cycle.

CIP makes use of the principle proposed by the French scientist Blaise Pascal, which states that a change in pressure in an enclosed incompressible fluid is conveyed undiminished to every part of the fluid and to the surface of its container. Powder materials are sealed in a forming mold with low deformation resistance, such as a rubber bag, and liquid pressure is applied to compress the molded body uniformly over its entire surface.

Metal mold pressing is a similar pressing method to CIP. In this method, powder materials are filled into a space enclosed by a metal mold and a lower punch. They are then compressed by narrowing the distance between the upper and lower punches.

The benefits of high initial density in speeding up consolidation to final density in the thermal cycle

The high initial density achieved through the CIP process offers several benefits in the consolidation of powders. These benefits include:

-

Predictable compression during the subsequent sintering process: High compaction and uniform density provide predictable compression during the sintering process, resulting in consistent and reliable final density.

-

Ability to process large, complicated, and perfect shapes: CIP enables the processing of large and complex shapes with high precision. This saves time and cost during after-treatment processes.

-

Generation of large aspect ratio parts with uniform densities: CIP can produce parts with aspect ratios greater than 2:1, maintaining uniform densities throughout the component.

-

Green strength for in-process handling and treatment: The green compact formed through CIP has sufficient strength to undergo in-process handling and treatment, reducing production costs.

Overall, the CIP process offers efficient and effective shaping and compaction of powders, resulting in high-quality components with desired densities. Its versatility and ability to process various materials make it a valuable method in industries such as precision manufacturing, aerospace, defense, and automotive.

According to a report by DataIntelo, the Global Cold Isostatic Pressing (CIP) Equipment Market is projected to grow at a substantial CAGR during the forecast period, 2020-2026. The increasing demand for CIP-processed products in industries like precision manufacturing, aerospace, defense, and automotive is driving this growth.

The Hot Isostatic Pressing (HIP) Process

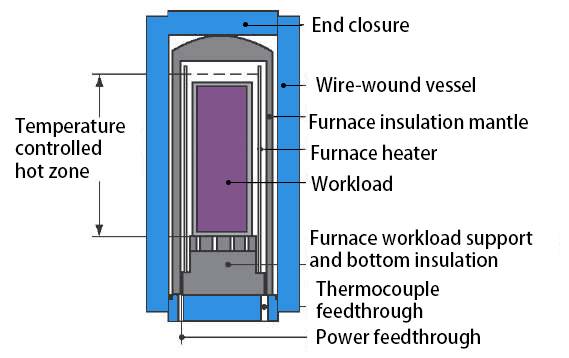

The leverage of uniaxial pressure-assisted sintering in HIP

Pressure can also be applied during the thermal cycle. In uniaxial pressure-assisted sintering, typically only plate-like products can be produced. For more complex parts, Hot Isostatic Pressing (HIP) is used. HIP is carried out in a gaseous atmosphere, so the major requirement is that the outer surface of the treated parts be gas tight to start with. As such, this process can be used to produce components by vacuum sealing part powder in a mild steel shell. The uniform application of pressure ensures the shape is retained as the part and shell shrinks. Powders processed using a HIP strategy are typically not compatible with melting processes, either requiring excessive temperatures or yielding unfavorable microstructures. Nonetheless, the extra effort that is made to process these materials indicates their use in demanding applications where even a low level of porosity is not acceptable.

The requirements and results of the HIP process

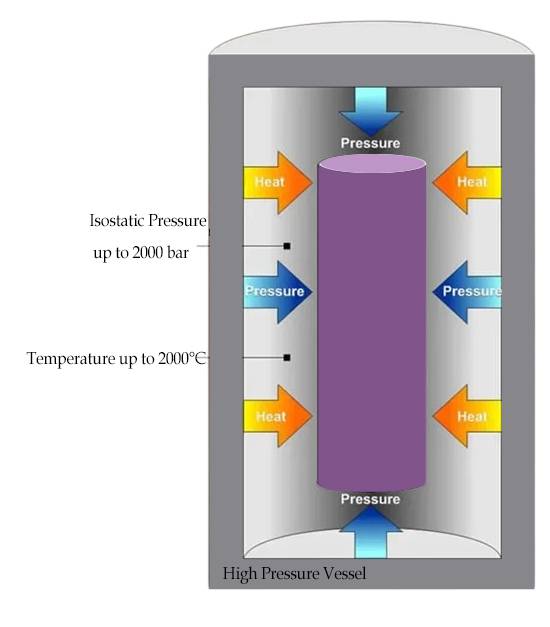

Hot Isostatic Pressing (HIP) is the simultaneous application of high temperature and pressure to metals and other materials for a specified amount of time in order to improve their mechanical properties. In the HIP unit, a high temperature furnace is enclosed in a pressure vessel. The temperature, pressure, and process time are all precisely controlled to achieve the optimum material properties. Parts are heated in an inert gas, generally argon, which applies "isostatic" pressure uniformly in all directions. This causes the material to become "plastic" allowing voids to collapse under the differential pressure. The surfaces of the voids diffusion bond together to effectively eliminate the defects achieving near theoretical density while improving mechanical properties of the parts such as investment castings.

The incompatibility of powders processed using a HIP strategy with melting processes

Hot Isostatic Pressing (HIP) is a material treatment process that involves the use of heat and pressure to improve the physical properties of a material. It’s typically performed on metals and ceramics. When either of these types of materials are exposed to heat and pressure, their physical properties change. HIP is an effective process to eliminate defects in powder-based additively manufactured parts, generating 100% dense material with improved fatigue properties and ductility.

Sectors HIP has come into its own since it reached a comparable scale to castings and forgings and has become recognized as an economic competitor to forging and casting in applications with higher raw material costs. There are currently three main HIP sectors: Oil and gas, Power generation, and Aerospace. The production of a PM HIP component is leaner and shorter than the usual conventional metallurgy processes. The cost of HIP relative to energy and materials costs has decreased by 65% over the last two decades.

Introduction Hot Isostatic Pressing (HIP) is a process to densify powders or cast and sintered parts in a furnace at high pressure (100-200 MPa) and at temperatures from 900 to 1250°C, for example, for steels and superalloys. The gas pressure acts uniformly in all directions to provide isotropic properties and 100% densification. It provides many benefits and has become a viable and high-performance alternative to conventional processes such as forging, casting, and machining in many applications.

Sintering/Powder Metallurgy: Hot Isostatic Pressing (HIP) Technology

Hot Isostatic Pressing has gone from the research lab to full-scale regular production in the course of the last 50 years. The future of this technology looks bright as the demand for improved material properties, the use of powder materials, and the desire to produce net or near-net shape parts accelerates.

Resistance-heated furnace temperature source inside the vessel

The HIP process, originally known as gas-pressure bonding, was developed at Battelle Memorial Institute's Columbus, Ohio, laboratory in 1955. The original application was the diffusion bond cladding of zirconium to zirconium-uranium alloys for nuclear fuel elements. Around the same time, ASEA-Sweden was utilizing the isostatic application of pressure to compact the first synthetic diamonds. Hot isostatic pressing (HIP) is a manufacturing process used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

What is Hot Isostatic Pressing (HIP)?

Hot Isostatic Pressing (HIP), or ‘Hipp’ing’, is the simultaneous application of heat and high pressure to materials. This process is ideal to improve the characteristics of your additive manufactured product by removing the porosity up to 100%.

Today, this process is already used in the improvement of additive manufactured products. Following Hipp’ing, the result is the elimination of internal voids (i.e. porosity) and improved microstructure, leading to hugely improved mechanical properties. HIP can be applied to a large range of alloys, including titanium, steels, aluminum, copper, and magnesium.

The Opportunity for Single Step Pre-Processing of Constructs via Multi-Material Additive Manufacturing

The potential benefits of multi-material additive manufacturing in both CIP and HIP processes

Multi-material additive manufacturing offers a range of potential benefits in both the Consolidation by Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) processes. By using selective powder deposition, this approach can bridge the gap between new additive manufacturing technology and traditional manufacturing methods for high-end components. By consolidating parts using established technology, it can help alleviate concerns about the quality and reliability of AM-produced items.

One of the key advantages of multi-material additive manufacturing is the decrease in manufacturing costs. With increased part complexity, fewer processing steps, and reduced time, manufacturers can achieve cost savings. This is particularly beneficial for producing small series or prototypes, where efficiency and cost-effectiveness are crucial.

The potential decrease in manufacturing costs with increased part complexity, fewer processing steps, and time

The use of multi-material additive manufacturing can lead to a decrease in manufacturing costs. Traditional subtractive manufacturing methods have geometric limits that no longer apply with additive manufacturing. This means that complex shapes and designs can be created without significantly increasing production costs. Additionally, the ability to create multiple versions of the same product without varying the cost of production can further reduce costs.

Another significant advantage of multi-material additive manufa

cturing is the drastic reduction of processing waste. By adding material step by step until the desired object is obtained, there is minimal waste compared to traditional subtractive manufacturing methods. This not only reduces costs but also contributes to a more sustainable manufacturing process.

The world of metal additive manufacturing is experiencing a notable increase in the use of methods such as Metal Injection Molding (MIM), Binder Jetting (BJ), and Fused Deposition Modeling (FDM). These methods offer unique advantages in terms of cost, design flexibility, and material properties.

In metal additive manufacturing, thermal debinding is a crucial process after printing. It involves removing binders and other additives to obtain a fully dense metal part. Properly debinding parts produced by metal additive manufacturing is essential for achieving the desired mechanical properties and dimensional accuracy.

Both the CIP and HIP processes utilize multi-material constructs. CIP involves the use of polymer shells with ceramic powders, while HIP uses welded mild steel sheet material casing with high-end powder metallurgy alloys. These methods present an opportunity for single-step pre-processing of constructs via multi-material additive manufacturing.

This approach is particularly beneficial for producing small series or prototypes, as it allows for increased part complexity with fewer processing steps and less time. By leveraging the advantages of multi-material additive manufacturing, manufacturers can achieve improved efficiency and cost-effectiveness in their production processes.

The industrial base for the HIP process is expanding rapidly due to the growing demand for improved material properties and the use of powder materials. Additionally, advancements in HIP equipment, shorter processing times, and improving economics make the HIP process a viable choice for a wide range of materials. This further reinforces the potential for single-step pre-processing of constructs via multi-material additive manufacturing.

In conclusion, multi-material additive manufacturing offers significant opportunities for improving efficiency, reducing costs, and achieving complex designs in both the CIP and HIP processes. By leveraging the advantages of this technology, manufacturers can stay at the forefront of innovation and meet the demands of today's competitive market.

The Use of kintek's Selective Deposition Technology in Isostatic Pressing

The simultaneous deposition of different materials

Isostatic pressing is a method of compacting powder in an elastomeric container submerged in a fluid at high pressure. Traditionally, this process has been used primarily for ceramics and metals. However, recent advancements in selective deposition technology, such as kintek's innovative approach, have opened up new possibilities for isostatic pressing.

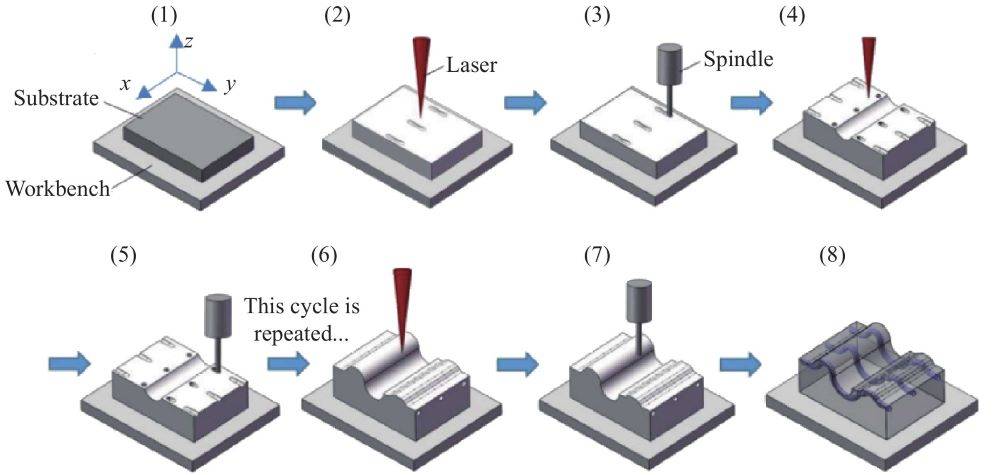

KinTek's selective deposition technology allows for the simultaneous deposition of different materials. This means that instead of using a single powder material, multiple materials can be deposited layer by layer. This opens up a range of possibilities for creating complex, multi-material parts with unique properties.

Creating a shaped, liquid-tight polymer shell surrounding uncompacted ceramic powder

One of the key advantages of KinTek's selective deposition technology in isostatic pressing is the ability to create a shaped, liquid-tight polymer shell surrounding uncompacted ceramic powder. This shell acts as a barrier, preventing the ceramic powder from dispersing during the isostatic pressing process.

By using selective deposition to create this shell, it is possible to achieve a uniform green density even for large height/diameter ratio parts. This is particularly important for applications where dimensional control is crucial, such as in the aerospace or automotive industries.

The easy transportation and placement of the construct inside a CIP machine

Another benefit of 's selective deposition technology is the ease of transportation and placement of the construct inside a cold isostatic pressing (CIP) machine. The construct, consisting of the shaped polymer shell filled with uncompacted ceramic powder, can be easily handled and positioned within the CIP machine.

This ease of transportation and placement not only increases efficiency but also reduces the risk of damage to the construct during the loading process. It allows for a more streamlined and reliable isostatic pressing process, ensuring consistent results and high-quality parts.

In conclusion, 's selective deposition technology offers exciting possibilities for isostatic pressing. The simultaneous deposition of different materials, the creation of a shaped, liquid-tight polymer shell, and the easy transportation and placement of the construct inside a CIP machine all contribute to the advancement of this manufacturing process. With further development and refinement, 's technology has the potential to revolutionize the way we produce complex, multi-material parts with improved dimensional control and performance.

The Potential of a Similar Approach for Parts Processed Using HIP

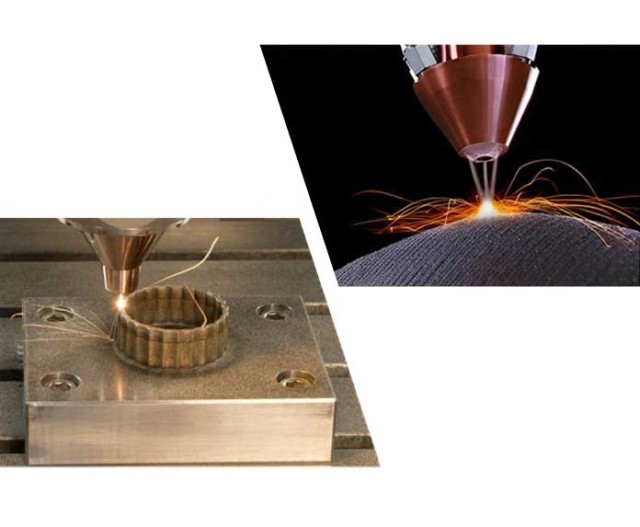

Co-depositing a mild tool steel and a PM specific alloy using a selective powder deposition system

For parts that must be processed using HIP, a similar approach could be used. A mild tool steel and a PM specific alloy could be co-deposited using a selective powder deposition system, and only the tool steel exterior would need to be consolidated. As the PM alloy does not need to be melted it is easy to imagine producing a prefilled casing with piping that would enable weld sealing this casing under vacuum, just as in HIP-produced parts produced from welded sheet metal. The rest of the HIP processing can then follow the traditional route.

Producing a prefilled casing with piping for weld sealing under vacuum

A similar approach to HIP processing can be used for parts that require HIP treatment. By co-depositing a mild tool steel and a PM specific alloy using a selective powder deposition system, it is possible to produce a prefilled casing with piping for weld sealing under vacuum. This allows for the consolidation of the tool steel exterior while preserving the integrity of the PM alloy. The remaining HIP processing can then proceed as usual.

The traditional route of the rest of the HIP processing

After the co-deposition of a mild tool steel and a PM specific alloy using a selective powder deposition system and the consolidation of the tool steel exterior, the rest of the HIP processing can follow the traditional route. This includes the use of advanced cooling technology to enhance processing economics and improve final material properties. With the ability to cool down faster using argon gas and internal cooling systems, HIP cycles can be significantly reduced, leading to cost savings and improved part quality.

The use of HIP in various industries has proven to be highly beneficial. HIP can be used to manufacture a wide range of components, including large and massive near net shape metal components such as oil & gas parts and net shape impellers. It is also suitable for producing small PM HSS cutting tools and tiny parts such as dental brackets. The process has evolved over the years to become a high-performance, high-quality, and cost-effective method for producing metal and ceramic components.

HIPing offers numerous benefits, including improved mechanical properties, reduced scrap, minimized machining, and the ability to rejuvenate old parts. It can be applied to a variety of materials, including aluminum, steel, stainless steel, superalloy, titanium, and ceramics. With advancements in HIP equipment and processing times, the HIP process is becoming increasingly popular for a wide range of materials and applications.

In conclusion, a similar approach to HIP processing can be applied to parts that require HIP treatment. By co-depositing a mild tool steel and a PM specific alloy using a selective powder deposition system, it is possible to produce prefilled casings with piping for weld sealing under vacuum. This approach offers numerous benefits, including improved part quality, reduced processing time, and cost savings. With the continuous advancements in HIP technology, the potential for using this approach in various industries continues to expand.

Conclusion: The Bridge of Selective Powder Deposition between New Additive Manufacturing and Traditional Manufacturing

The potential of selective powder deposition in creating a bridge between new additive manufacturing technology and traditional manufacturing of high-end components

Selective powder deposition has the potential to bridge the gap between new additive manufacturing (AM) technology and traditional manufacturing of high-end components. This approach takes advantage of the well-understood pressure treatment and thermal cycling processes that are already available in the industry. By using these established methods to consolidate parts created via AM, it can help ease industry anxiety about items produced through this new technology.

The possibility of easing industry anxiety about items produced via AM through this approach

One of the main concerns in the industry when it comes to additive manufacturing is the quality and reliability of the final products. Traditional manufacturing methods have been refined over decades, and there is a level of trust and confidence in the components produced through these processes.

By using selective powder deposition, the parts created through AM can be shaped using the new technology but consolidated using the long-established methods. This can help alleviate some of the anxiety surrounding the use of AM for high-end components.

In conclusion, selective powder deposition offers a promising solution to bridge the gap between new additive manufacturing technology and traditional manufacturing. By leveraging the established processes and techniques in traditional manufacturing, it can help build trust and confidence in the components produced through AM.

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Related Articles

- Understanding Cold Isostatic Pressing and its Types

- Cold Isostatic Pressing: An Overview and its Industrial Applications

- Cold Isostatic Pressing (CIP): A Proven Process for High-Performance Parts Manufacturing

- Hot & Cold Isostatic Pressing: Applications, Process, and Specifications

- Understanding Cold Isostatic Pressing Method for Powdered Materials