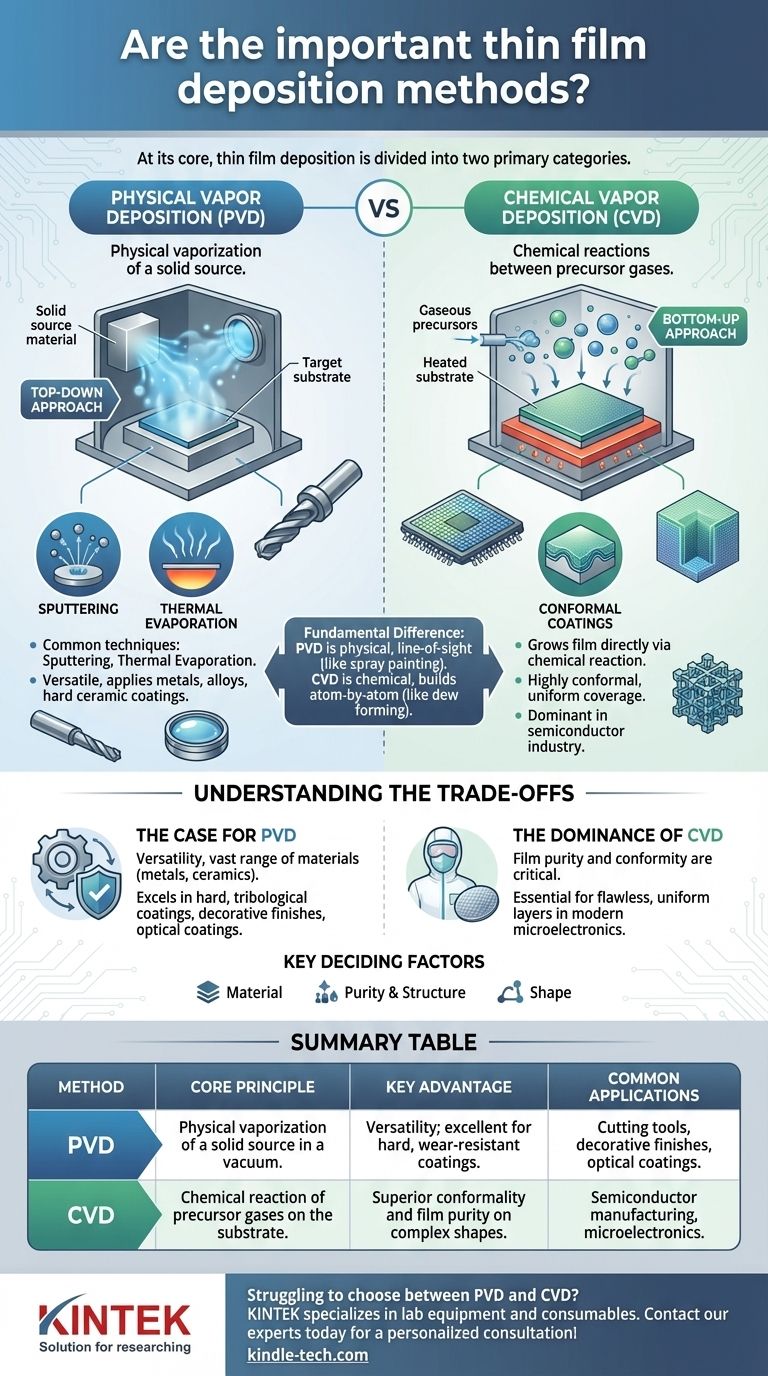

At its core, thin film deposition is divided into two primary categories. These foundational techniques are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). PVD involves physically vaporizing a solid source material in a vacuum and depositing it onto a surface, while CVD uses chemical reactions between precursor gases to grow a film directly on the substrate.

The fundamental difference lies in how the material travels to the surface. PVD is a physical, line-of-sight process akin to spray painting, whereas CVD is a chemical process that builds the film atom-by-atom, much like dew forming uniformly on a surface.

Deconstructing the Core Methods

Thin film deposition is the process of applying a very thin layer of material, from nanometers to micrometers thick, onto a surface or "substrate." This imparts new properties—such as wear resistance, optical reflection, or electrical conductivity—that the substrate material does not possess on its own.

Physical Vapor Deposition (PVD)

PVD encompasses a set of vacuum deposition methods that use physical processes to produce a vapor of material, which then condenses on the object to be coated.

Think of this as a "top-down" approach. You start with a solid block of the coating material, turn it into a vapor, and transport that vapor onto your target.

Common PVD techniques include sputtering and thermal evaporation. These methods are highly versatile and widely used for applying metals, alloys, and hard ceramic coatings.

Chemical Vapor Deposition (CVD)

CVD involves introducing volatile precursor gases into a chamber. These gases then react or decompose on the substrate's surface to produce the desired high-purity, high-performance thin film.

This is a "bottom-up" approach. The film is built directly on the surface through a chemical reaction, not by transporting an existing solid.

Because it relies on a chemical reaction rather than a line-of-sight path, CVD is exceptional at creating highly conformal coatings that uniformly cover even complex, non-flat surfaces. This precision makes it the dominant method in the semiconductor industry.

Understanding the Trade-offs

The choice between PVD and CVD is not about which is "better" overall, but which is the correct tool for a specific engineering goal. The decision hinges on the desired film properties, the substrate material, and the geometry of the part being coated.

The Case for PVD

PVD processes are often chosen for their versatility and ability to deposit a vast range of materials, including metals and ceramics that are difficult to produce as precursor gases for CVD.

It excels in applications like creating hard, tribological coatings for cutting tools, durable decorative finishes on consumer products, and optical coatings for lenses and mirrors.

The Dominance of CVD

CVD is the undisputed leader where film purity and conformity are the most critical requirements. Its ability to grow flawless, uniform layers is essential for building the intricate, multi-layered structures found in modern microelectronics.

It is the cornerstone of semiconductor manufacturing, used to create the high-purity silicon, silicon dioxide, and other layers that form transistors and integrated circuits.

Key Deciding Factors

The decision typically comes down to three factors: the material you need to deposit, the required purity and structure of the final film, and the shape of the object you are coating. If the goal is a pure, uniform layer on a complex shape, CVD is often the superior choice. If the goal is a hard, wear-resistant metallic coating, PVD is the standard.

Making the Right Choice for Your Application

Selecting the correct deposition method requires a clear understanding of your primary technical objective.

- If your primary focus is creating high-purity, defect-free layers for electronics: CVD is the industry-standard method due to its unparalleled precision and control.

- If your primary focus is enhancing the surface properties of a tool or component with a hard coating: PVD techniques like sputtering are the most direct and effective solution.

- If your primary focus is uniformly coating a complex, three-dimensional object: CVD's chemical, non-line-of-sight nature provides superior conformal coverage.

Ultimately, choosing the right deposition method is about controlling matter at the atomic scale to achieve a specific engineering outcome.

Summary Table:

| Method | Core Principle | Key Advantage | Common Applications |

|---|---|---|---|

| PVD (Physical Vapor Deposition) | Physical vaporization of a solid source in a vacuum | Versatility; excellent for hard, wear-resistant coatings | Cutting tools, decorative finishes, optical coatings |

| CVD (Chemical Vapor Deposition) | Chemical reaction of precursor gases on the substrate | Superior conformality and film purity on complex shapes | Semiconductor manufacturing, microelectronics |

Struggling to choose between PVD and CVD for your project? The right deposition method is critical to your success. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and reliable solutions. Our team can help you select the perfect system to achieve the precise film properties your application demands, ensuring optimal performance and efficiency.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production