Yes, a diamond tester can absolutely be wrong. Basic, widely available diamond testers are useful for screening out obvious fakes like glass or cubic zirconia, but they are notoriously fooled by moissanite. Their accuracy also depends heavily on proper technique and the condition of the stone being tested.

The core issue is that common diamond testers measure only one physical property—usually thermal conductivity. While this is great for spotting simple imitations, sophisticated fakes like moissanite have similar thermal properties to diamond, leading to a false positive. True verification requires more than a single test.

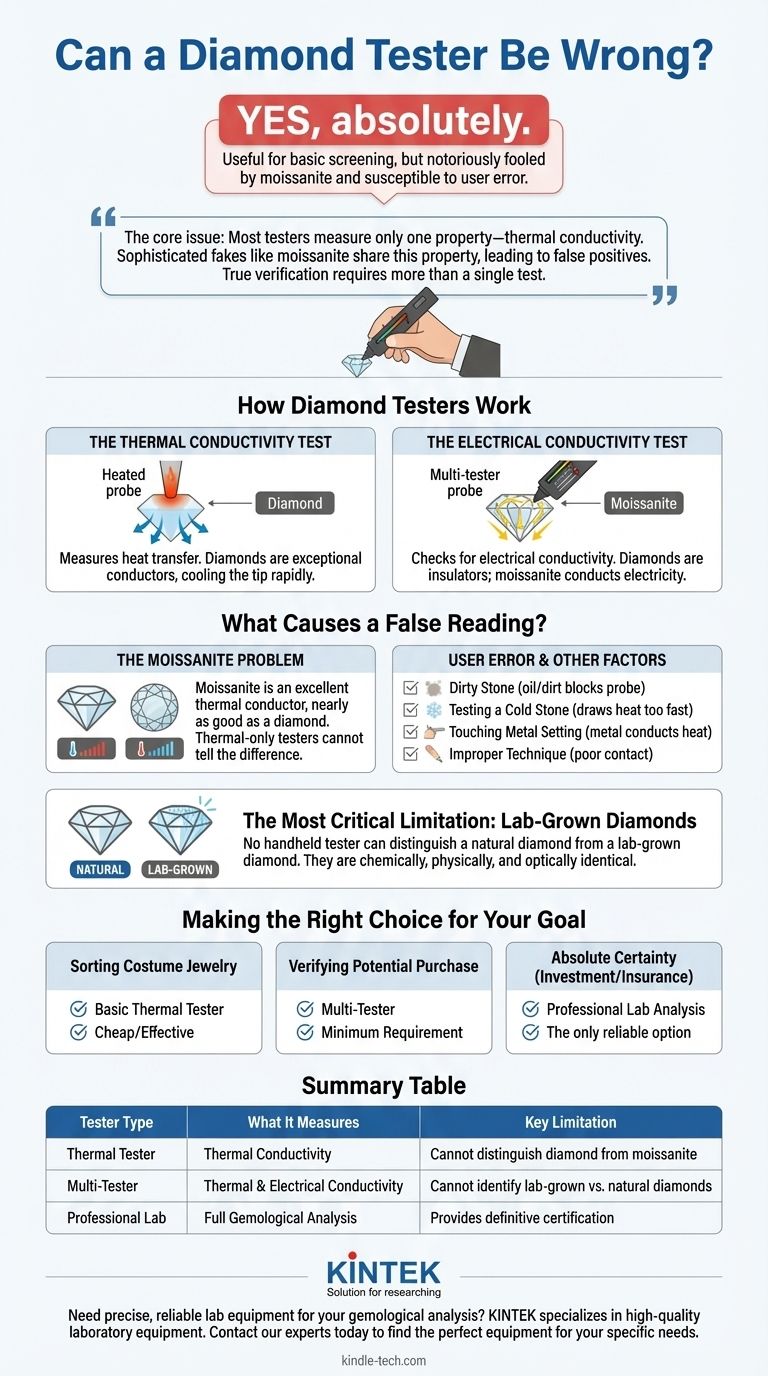

How Diamond Testers Work

To understand why a tester can fail, you first need to understand the principles it uses to identify a diamond. Testers primarily rely on measuring how a stone responds to heat or electricity.

The Thermal Conductivity Test

The most common and affordable testers are thermal probes. They work on a simple principle: diamonds are incredibly efficient at pulling heat away from a source.

The device has a small, heated metal tip. When you press this tip against a gemstone, the tester measures how quickly the heat is conducted away from the tip. Because diamonds are exceptional thermal conductors, they will cool the tip down very rapidly, causing the device to signal "Diamond."

The Electrical Conductivity Test

More advanced devices, often called multi-testers, add a second test: electrical conductivity. This was developed specifically to solve the moissanite problem.

A diamond is an electrical insulator, meaning it does not conduct electricity. Moissanite, on the other hand, is an electrical conductor. A multi-tester will first check thermal conductivity and then, if it gets a positive reading, will also check for electrical conductivity. If it conducts electricity, it will identify the stone as moissanite.

What Causes a False Reading?

A tester can be wrong for two main reasons: it's tricked by another stone, or the test itself is performed incorrectly.

The Moissanite Problem

Moissanite is the single biggest reason for false positives from basic thermal testers. This lab-created gemstone is also an excellent thermal conductor, nearly as good as a diamond.

A thermal-only tester cannot tell the difference. It will read the high thermal conductivity of moissanite and incorrectly signal that it is a diamond. This is not a malfunction; it is a fundamental limitation of the technology.

User Error and Other Factors

Even the best tool is useless if used improperly. Several common mistakes can lead to inaccurate results:

- Dirty Stone: Oil and dirt on the gemstone can act as an insulator, blocking the probe from making good contact and potentially causing a false negative.

- Testing a Cold Stone: If the gem is cold, it can draw heat away from the probe faster than normal, potentially causing a non-diamond to register as a diamond.

- Touching the Metal Setting: If the tester's tip accidentally touches the metal of the ring or jewelry setting, it will give a false reading, as metal is a superb conductor.

- Improper Technique: Not holding the probe perpendicular to a flat facet of the stone can result in poor contact and an inaccurate reading.

The Most Critical Limitation: Lab-Grown Diamonds

It is essential to understand one absolute fact: No handheld diamond tester can distinguish a natural diamond from a lab-grown diamond.

Lab-grown diamonds are not fakes; they are chemically, physically, and optically identical to diamonds mined from the earth. They have the same thermal and electrical properties. Only advanced, specialized laboratory equipment used by major gemological institutes can definitively identify their origin.

Making the Right Choice for Your Goal

Use a tester as a preliminary screening tool, not a final verdict. Your required level of certainty should dictate your method.

- If your primary focus is sorting costume jewelry from potential diamonds: A basic thermal tester is a cheap and effective tool for quickly weeding out glass and cubic zirconia.

- If your primary focus is verifying a potential diamond purchase from a non-certified seller: A multi-tester that checks for both thermal and electrical conductivity is the minimum requirement to avoid being fooled by moissanite.

- If your primary focus is absolute certainty for an investment, insurance, or peace of mind: The only reliable option is to submit the stone to a reputable gemological laboratory (like the GIA or AGS) for a full grading report.

Ultimately, a handheld tester is a guide for your investigation, but professional certification is the only true guarantee.

Summary Table:

| Tester Type | What It Measures | Key Limitation |

|---|---|---|

| Thermal Tester | Thermal Conductivity | Cannot distinguish diamond from moissanite |

| Multi-Tester | Thermal & Electrical Conductivity | Cannot identify lab-grown vs. natural diamonds |

| Professional Lab | Full Gemological Analysis | Provides definitive certification |

Need precise, reliable lab equipment for your gemological analysis?

KINTEK specializes in high-quality laboratory equipment and consumables, providing the tools professionals trust for accurate material testing. Whether you're verifying gemstones or conducting advanced research, our solutions deliver the reliability your work demands.

Contact our experts today to find the perfect equipment for your laboratory's specific needs and ensure your results are beyond doubt.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What is the significance of compression set? Predict Material Failure and Ensure Long-Term Reliability

- What is the water content of pyrolysis oil? A Key Factor in Bio-Oil Quality and Use

- Why are PTFE beakers required for hafnium metal ICP-OES validation? Ensure Pure Sample Dissolution

- Is there a battery tester for lithium batteries? Unlock Accurate Health Diagnostics Beyond Voltage

- How do you test a lithium battery to see if it's good? A Guide to Measuring Voltage, Capacity & Health