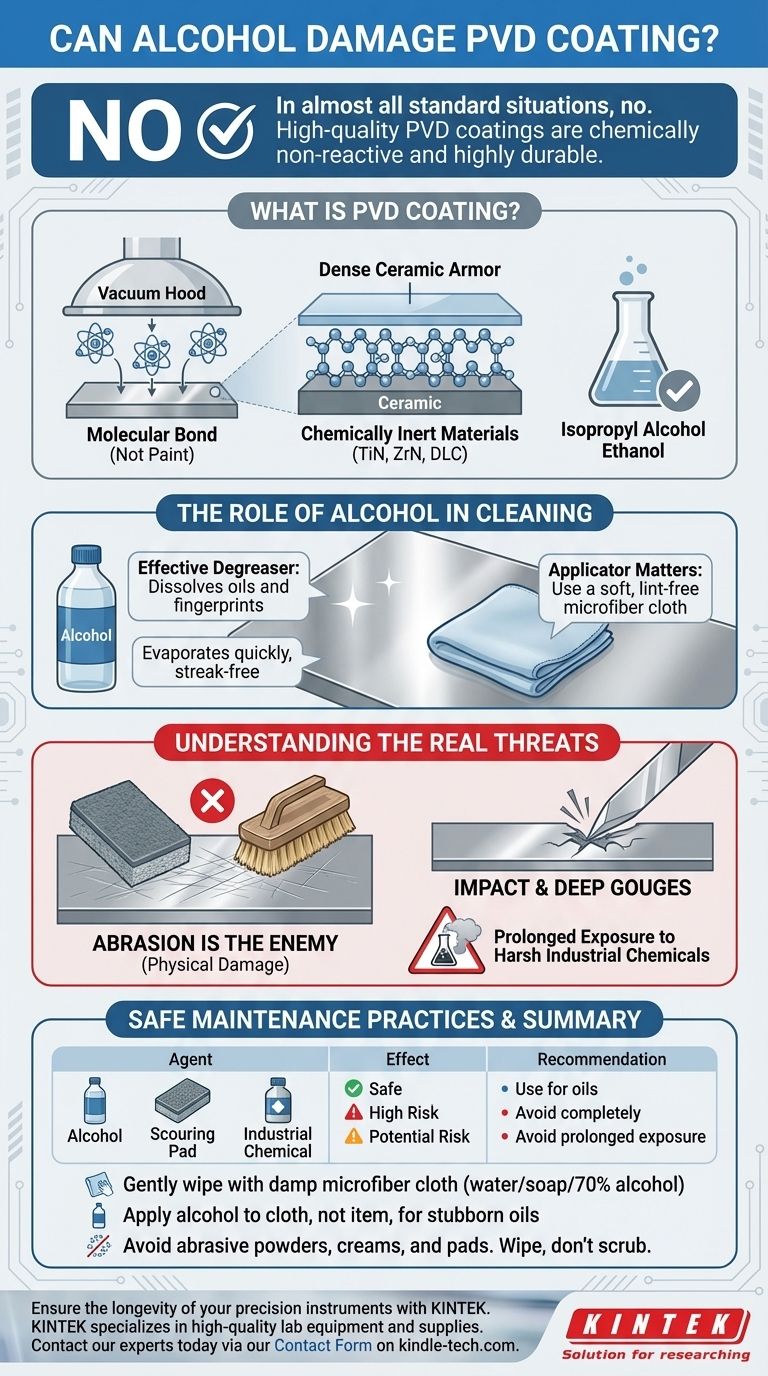

In almost all standard situations, no. High-quality Physical Vapor Deposition (PVD) coatings are specifically engineered to be chemically non-reactive and highly durable. Common alcohols like isopropyl or ethanol are not only safe but are often the recommended cleaning agents for removing oils and fingerprints from PVD surfaces without causing damage.

The primary threat to a PVD coating is not chemical, such as from alcohol, but physical. Abrasive materials and harsh scrubbing are far more likely to cause damage than the solvent itself.

What is PVD Coating and Why is it So Resilient?

To understand why alcohol is safe, it's essential to understand what a PVD coating is. It is fundamentally different from paint or traditional plating.

Not a Paint, but a Molecular Bond

PVD is a process conducted in a vacuum where a solid material (like titanium or zirconium) is vaporized and then deposited, atom by atom, onto a substrate.

This creates an extremely thin, hard, and dense ceramic layer that is metallurgically bonded to the surface. Think of it less like a coat of paint and more like an inseparable layer of ceramic armor.

The Chemical Inertness of PVD Materials

The materials used for PVD coatings, such as Titanium Nitride (TiN), Zirconium Nitride (ZrN), and Diamond-Like Carbon (DLC), are chosen for their stability.

These materials are chemically inert, meaning they do not readily react with common substances, including solvents like alcohol, mild acids, or alkaline solutions. Their atomic structure is stable and resists chemical attack.

The Role of Alcohol in Cleaning PVD Surfaces

Because of its properties, alcohol is an excellent choice for maintaining PVD-coated items.

An Effective Degreaser

The main purpose of using alcohol for cleaning is to act as a solvent. It excels at dissolving and lifting away fingerprints, oils, and other organic residues that can dull the appearance of the finish.

Unlike some soap-based cleaners, it evaporates quickly and cleanly, leaving behind a streak-free surface without any film.

The Applicator is More Important than the Solvent

The key to safe cleaning is the material you use to apply the alcohol. A soft, lint-free microfiber cloth is the ideal choice.

Using a rough paper towel or a dirty rag introduces abrasive particles that can create micro-scratches, even on a hard PVD surface.

Understanding the Real Threats to PVD Coatings

While resistant, PVD coatings are not indestructible. The danger comes from physical force, not from a simple chemical wipe-down.

Abrasives are the True Enemy

The single greatest risk to a PVD finish is abrasion. Abrasive cleaners (like powders), scouring pads, steel wool, or even the abrasive side of a kitchen sponge can permanently scratch and wear down the coating.

This physical damage strips the coating away, exposing the substrate underneath. Once scratched, the coating cannot be repaired; the part must be completely re-coated.

Harsh Industrial Chemicals

While consumer-grade alcohol is safe, prolonged exposure to highly corrosive industrial chemicals, such as strong acids or bases, could potentially etch the surface. However, these are not substances you would encounter in typical household cleaning.

Impact and Deep Gouges

PVD coatings are extremely hard, which makes them scratch-resistant, but they are also very thin. A sharp impact or a deep gouge that deforms the metal underneath can cause the coating to chip, crack, or flake at the point of impact.

How to Safely Maintain Your PVD-Coated Items

Proper care is simple and ensures the finish lasts for the life of the product.

- For routine cleaning of items like watches or faucets: Gently wipe the surface with a soft microfiber cloth slightly dampened with water and mild soap, or a 70% isopropyl alcohol solution.

- For removing stubborn oils or fingerprints: Apply a small amount of isopropyl alcohol directly to a clean microfiber cloth (not the item itself) and wipe the affected area in a gentle, circular motion.

- To preserve the finish for the long term: Strictly avoid all abrasive powders, creams, and scouring pads. Always remember to wipe, never scrub.

By understanding that PVD's primary vulnerability is physical abrasion, not chemical reaction to alcohol, you can confidently maintain its pristine finish for years to come.

Summary Table:

| Agent | Effect on PVD Coating | Recommendation |

|---|---|---|

| Isopropyl / Ethanol Alcohol | Safe, Often Recommended | Ideal for removing oils and fingerprints. |

| Abrasive Cleaners / Pads | High Risk of Damage | Avoid completely to prevent scratches. |

| Harsh Industrial Chemicals | Potential Risk (Prolonged Exposure) | Not a concern for typical household cleaning. |

Ensure the longevity of your precision instruments with the right equipment and consumables. KINTEK specializes in high-quality lab equipment and supplies, helping laboratories maintain their valuable assets, from PVD-coated components to sensitive analytical tools. Contact our experts today via our Contact Form to discuss how we can support your lab's specific needs for durability, cleanliness, and performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application