In short, no, high-quality dental ceramics do not stain. Unlike the porous enamel of your natural teeth, materials like porcelain and zirconia are non-porous and manufactured to be incredibly color-stable. However, the areas around the ceramic restoration can stain, which is often mistaken for the ceramic itself changing color.

The core issue isn't the ceramic material, but the integrity of its bond to your natural tooth. Discoloration almost always originates from the bonding agent at the restoration's edge or from changes in the underlying natural tooth.

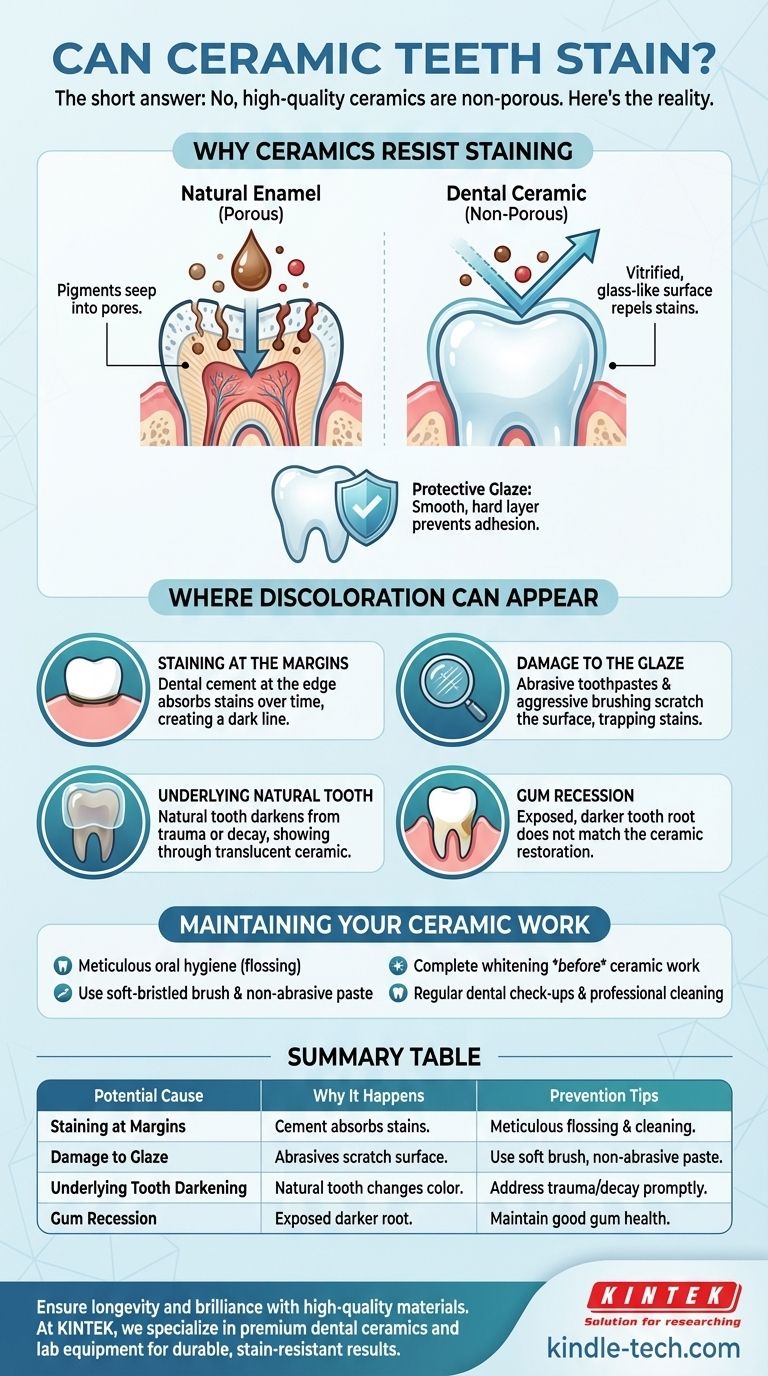

Why Dental Ceramics Resist Staining

The remarkable stain resistance of modern dental ceramics is not an accident; it's a result of their fundamental material properties. Understanding this is key to appreciating their longevity.

The Non-Porous Surface

Your natural tooth enamel is filled with microscopic pores. Pigments from coffee, tea, and wine seep into these pores, causing intrinsic stains.

Dental ceramics, by contrast, are vitrified materials, meaning they are fired at high temperatures to create a glass-like, non-porous surface. Staining agents simply have nowhere to penetrate.

The Protective Glaze

The final step in fabricating a ceramic crown or veneer is the application of a protective glaze. This glaze is an extremely smooth and hard layer that makes it difficult for stain-causing molecules to adhere to the surface in the first place.

Think of it as the difference between a sealed granite countertop and an unsealed one. Spills wipe away cleanly from the sealed surface but can soak into the unsealed stone.

How Discoloration Can Still Occur

While the ceramic itself is stable, the entire dental restoration system has weak points where discoloration can appear over time. This is what you must monitor.

Staining at the Margins

This is the most common cause of perceived staining. The restoration is attached to your tooth with dental cement. Over years, this thin line of cement at the margin (the edge where ceramic meets tooth) can absorb stains. This creates a visible dark line around the edge of your crown or veneer.

Damage to the Glaze

While durable, the glaze is not indestructible. Using highly abrasive toothpastes (like some charcoal or whitening formulas) or aggressive brushing can create microscopic scratches on the surface. These rough patches can then trap stains, dulling the restoration's appearance.

The Underlying Natural Tooth

A veneer is a thin shell of ceramic bonded to the front of your tooth. If the natural tooth underneath darkens due to trauma, aging, or a new cavity, that darker color can show through the translucent ceramic, making the veneer appear discolored.

Gum Recession

If the gums recede around a crown, the root of the natural tooth can become exposed. Tooth roots are not covered in white enamel and have a naturally yellower, darker appearance that will not match the ceramic restoration.

Understanding the Trade-offs

Ceramic restorations are a fantastic solution, but it's critical to understand their limitations to ensure a successful long-term outcome.

Color Is Permanent

The color of your ceramic crown or veneer is selected and permanently fired in the lab. This is an advantage for stability, but it means the ceramic will not change color if you decide to whiten your surrounding natural teeth later. This can lead to a color mismatch.

Material Quality Varies

Not all ceramics are created equal. Modern materials like lithium disilicate (e.max) and zirconia offer superior strength and color stability compared to older feldspathic porcelains. The quality of the material and the skill of the dental lab are paramount.

How to Maintain the Appearance of Your Ceramic Work

Proper care is the deciding factor in the long-term aesthetic success of your dental work. Your goal is to protect the restoration and the health of the surrounding tissue.

- If your primary focus is preventing edge staining: Practice meticulous oral hygiene, focusing on daily flossing and gentle cleaning around the margins of the restoration to remove plaque before it can cause stains.

- If your primary focus is protecting the ceramic surface: Use only a soft-bristled toothbrush and a non-abrasive toothpaste to avoid scratching the glaze.

- If your primary focus is long-term color matching: Always complete any desired teeth whitening on your natural teeth before your dentist selects the final shade for your new ceramic work.

- If your primary focus is overall longevity: Attend regular dental check-ups and cleanings, as a professional can remove tough surface deposits without damaging the ceramic.

With the right care, your ceramic restorations will remain a stable and reliable component of your smile for many years.

Summary Table:

| Potential Cause of Discoloration | Why It Happens | Prevention Tips |

|---|---|---|

| Staining at the Margins | Dental cement at the edge absorbs stains over time. | Meticulous flossing and cleaning around the restoration. |

| Damage to the Glaze | Abrasive toothpastes scratch the surface, trapping stains. | Use a soft-bristled brush and non-abrasive toothpaste. |

| Underlying Tooth Darkening | The natural tooth underneath changes color. | Address tooth trauma or decay promptly with your dentist. |

| Gum Recession | Exposed, darker tooth root creates a mismatch. | Maintain good gum health through regular dental care. |

Ensure the longevity and brilliance of your dental restorations with high-quality materials. At KINTEK, we specialize in premium dental ceramics and lab equipment, providing dentists and labs with the reliable materials needed for durable, stain-resistant crowns, veneers, and bridges. Let us help you achieve superior results for your patients. Contact our experts today to learn more about our dental products and how we can support your practice.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- What is the significance of using a tube furnace with vacuum-sealed quartz tubes? Master Ceramic Synthesis

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the key differences between incineration and gasification? Explore Waste Management Solutions

- What is the difference between oxidizing and reducing environments? Key Insights for Chemical Reactions