Yes, crucibles are engineered specifically to withstand extremely high temperatures. Their core function is to contain materials for processes like metal melting, chemical analysis, and material synthesis at temperatures far beyond the tolerance of standard containers. However, the maximum temperature a crucible can handle is entirely dependent on the material from which it is made.

The critical factor is not whether a crucible can handle heat, but rather matching the specific crucible material—such as graphite, ceramic, or a metal alloy—to the temperature range and chemical environment of your application.

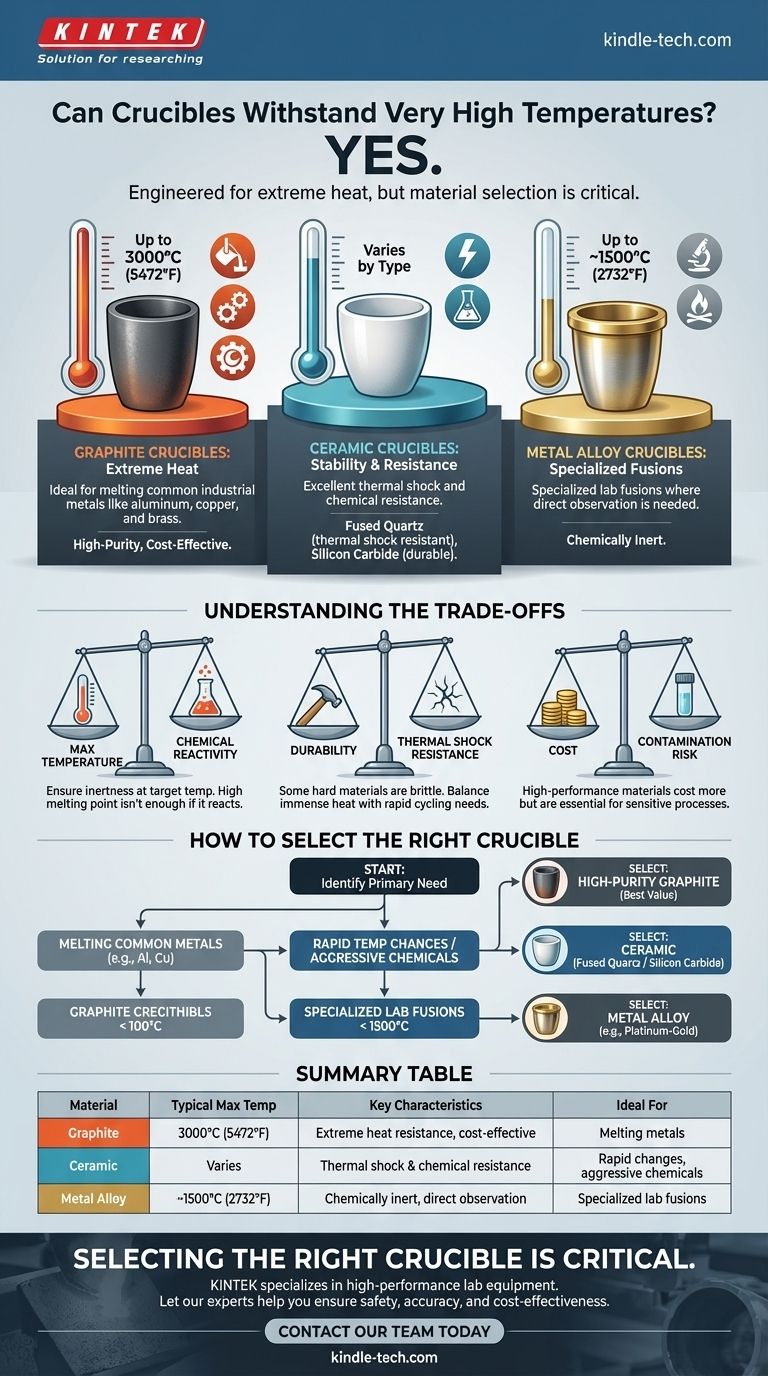

The Role of Material in Thermal Performance

A crucible's ability to resist heat is defined by its material composition. Each material offers a unique combination of thermal resistance, chemical inertness, and durability.

Graphite Crucibles: For Extreme Heat

High-purity graphite crucibles are the industry standard for many high-temperature applications. They are capable of withstanding temperatures up to 3000°C (5472°F).

This makes them ideal for melting common industrial metals like aluminum, copper, and brass without the risk of contamination or failure due to heat stress.

Ceramic Crucibles: For Stability and Resistance

Ceramic crucibles are valued for their stability and resistance to both thermal shock and chemical attack. Materials in this category include fused quartz, silicon carbide, and boron nitride.

- Fused quartz is exceptionally resistant to thermal shock, meaning it can handle rapid changes in temperature without cracking.

- Silicon carbide is known for its durability and is frequently used in demanding environments like semiconductor production.

- Boron nitride serves as an excellent thermal insulator, maintaining stable temperatures within the crucible.

Metal Alloy Crucibles: For Specific Lab Fusions

Certain applications use crucibles made from precious metal alloys, such as platinum-gold. These are more specialized and have a lower temperature ceiling.

For example, a platinum-gold crucible may have a maximum application temperature of 1500°C (2732°F), limited by the point at which the alloy itself begins to soften. They are often used for short-duration fusions where direct observation of the process is necessary.

Understanding the Trade-offs

Selecting a crucible involves more than just finding the highest temperature rating. You must balance thermal performance against other critical factors.

Maximum Temperature vs. Chemical Reactivity

A high melting point is useless if the crucible reacts with the substance it holds. While graphite has an exceptional temperature tolerance, it may not be suitable for materials that can react with carbon. You must ensure the crucible is chemically inert to your specific sample at the target temperature.

Durability vs. Thermal Shock Resistance

Some extremely hard and durable materials can be brittle. They may withstand immense, stable heat but crack if heated or cooled too quickly. Materials like fused quartz are less durable mechanically but offer superior performance in applications with rapid thermal cycling.

Cost vs. Contamination Risk

High-performance materials come at a higher cost. A standard graphite crucible may be cost-effective for melting brass, but a high-purity boron nitride or platinum crucible is a necessary expense for sensitive scientific or manufacturing processes where even minor contamination is unacceptable.

How to Select the Right Crucible

Base your choice on the specific demands of your task. A methodical approach ensures safety, accuracy, and cost-effectiveness.

- If your primary focus is melting common metals like aluminum or copper: A high-purity graphite crucible provides the best combination of extreme temperature resistance and value.

- If your work involves rapid temperature changes or aggressive chemicals: A ceramic crucible made from fused quartz or silicon carbide is the correct choice for its thermal and chemical stability.

- If you are performing specialized lab fusions below 1500°C: A specific metal alloy crucible, such as platinum-gold, may be required by your process protocol.

Choosing the right crucible is about understanding your process requirements and selecting the material engineered to meet them.

Summary Table:

| Crucible Material | Typical Max Temperature | Key Characteristics | Ideal For |

|---|---|---|---|

| Graphite | Up to 3000°C (5472°F) | Extreme heat resistance, cost-effective | Melting metals (e.g., aluminum, copper, brass) |

| Ceramic (e.g., Fused Quartz, Silicon Carbide) | Varies by type | Excellent thermal shock & chemical resistance | Rapid temperature changes, aggressive chemicals |

| Metal Alloy (e.g., Platinum-Gold) | Up to ~1500°C (2732°F) | Chemically inert, for direct observation | Specialized lab fusions, sensitive processes |

Selecting the right crucible is critical for your lab's success.

KINTEK specializes in high-performance lab equipment and consumables. Our experts can help you choose the perfect crucible material—whether you need extreme heat resistance, chemical stability, or contamination-free results—ensuring safety, accuracy, and cost-effectiveness for your specific application.

Contact our team today to discuss your high-temperature needs and find the ideal solution for your laboratory.

Visual Guide

Related Products

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- High Purity Pure Graphite Crucible for Evaporation

People Also Ask

- What are the common uses of crucible? Essential Guide for High-Temperature Processes

- Why are high-purity alumina crucibles preferred for TiO2 synthesis? Avoid Contamination in High-Performance Catalysts

- What are the technical advantages of using high-purity alumina crucibles? Optimize Phosphate Glass-Ceramic Melting

- Why is a clay graphite crucible preferred for the preparation of Al-1wt.%Fe-1wt.%Ni alloy solutions? Key Benefits Explained

- Why are high-purity graphite crucibles used for magnesium distillation? Ensure 3N8 Purity & Thermal Stability

- What can I use as a crucible for melting gold? Choose the Right Material for a Clean, Efficient Melt

- Can the same crucible be used for different metals? Avoid Costly Contamination and Crucible Failure

- Can you melt gold in a crucible? Yes, with the right crucible, heat source, and safety process.