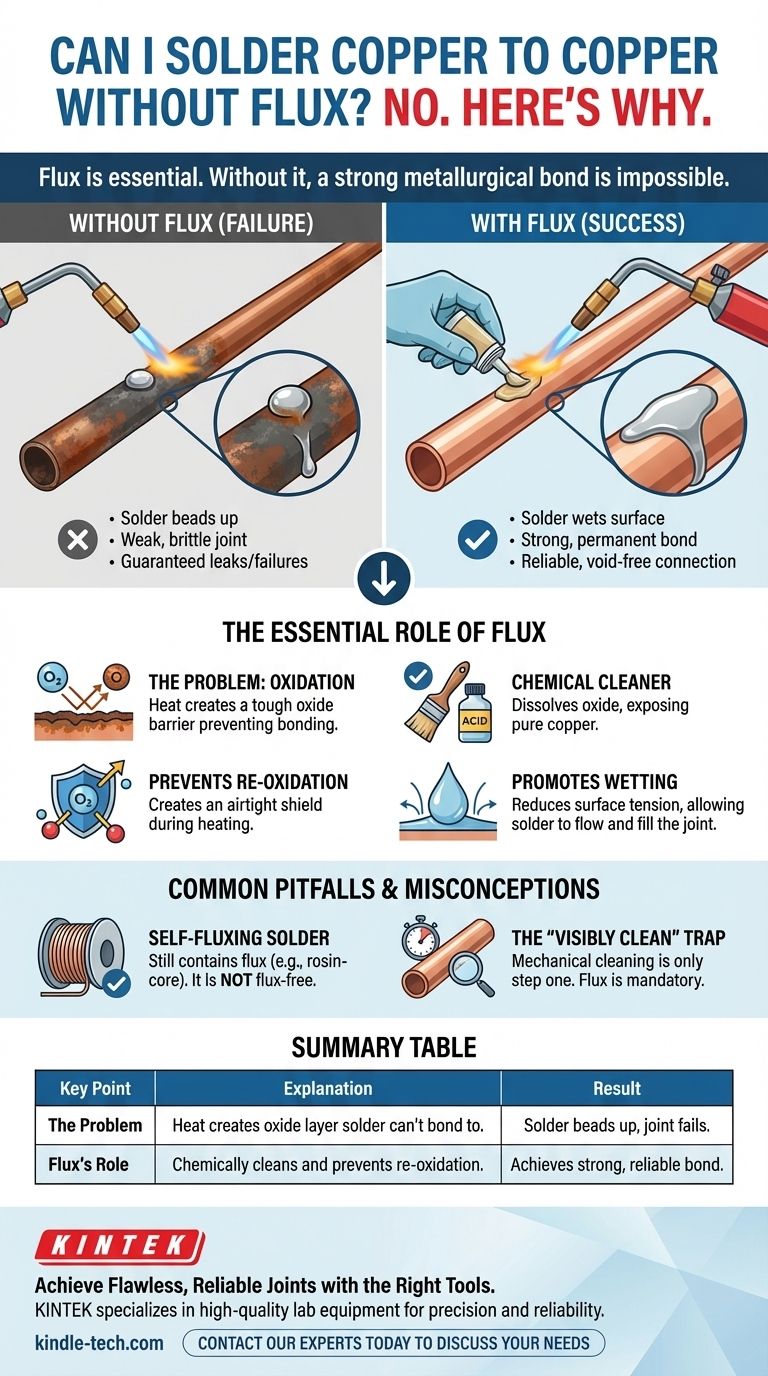

No, you cannot reliably solder copper to copper without using flux. Flux is not an optional additive but a fundamental chemical agent required for the process. Without it, the molten solder cannot form a strong, permanent metallurgical bond with the copper, leading to a weak joint that is guaranteed to fail.

The core problem is that the heat required for soldering creates an invisible layer of oxide on the copper's surface. Flux is the essential chemical cleaner that removes this oxide and prevents it from re-forming, allowing the solder to bond directly with the pure copper underneath.

The Essential Role of Flux in Soldering

To understand why flux is non-negotiable, you must first understand the primary obstacle in any soldering operation: oxidation.

The Problem of Oxidation

All metals react with oxygen in the air, forming a thin, invisible layer of metal oxide. Copper is particularly susceptible to this process.

When you apply a torch or a soldering iron, this chemical reaction accelerates dramatically. The very heat you need to melt the solder rapidly creates a tough layer of copper oxide.

Flux as a Chemical Cleaner

Mechanical cleaning with a wire brush or sandpaper is the first step, but it's not enough. Flux is an acidic chemical agent designed to solve the oxide problem.

When heated, flux becomes active and dissolves the existing layer of copper oxide, exposing the pure, raw metal beneath it.

Preventing Re-Oxidation

Just as importantly, the molten flux coats the cleaned copper, creating an airtight barrier. This shield prevents oxygen from reaching the hot copper surface while you apply the solder, stopping re-oxidation from occurring.

Promoting Solder Flow ("Wetting")

A clean, oxide-free surface allows the molten solder to flow freely and smoothly across the metal. This phenomenon, known as wetting, is critical.

Flux reduces the surface tension of the solder, allowing it to be drawn into a joint via capillary action. This ensures a complete, void-free connection.

What Happens When You Solder Without Flux?

Attempting to solder copper without flux is a predictable exercise in failure. The results are immediate and obvious.

The Solder Beads Up

Without flux to clean the surface, the molten solder will not "wet" the copper. Instead, it will bead up and roll off, much like water on a waxy surface. It will refuse to stick or flow into the joint.

A Weak, Brittle Bond

If you manage to get any solder to stick, it will form a purely mechanical "glob" on top of the oxide layer. It is not chemically bonded to the copper itself.

This connection is incredibly weak and brittle. It will break with minimal force and offers no structural integrity or reliable electrical conductivity.

Guaranteed Leaks and Failures

For plumbing applications, a joint made without flux will leak immediately under pressure. For electronics, it will result in a "cold" joint with a poor or non-existent electrical connection that will quickly fail.

Common Pitfalls and Misconceptions

Many beginners assume that if the copper looks clean, flux is unnecessary. This is a critical misunderstanding of the process.

Is "Self-Fluxing" Solder an Exception?

No. Solder described as "self-fluxing" or "flux-core" is not flux-free. It simply contains a core of flux within the solder wire itself.

For electronics, this is typically rosin-core solder. For some mechanical or plumbing work, acid-core solder is used. You are still using flux; it is just delivered in a different form.

What About Brazing?

Brazing is a similar process that uses higher temperatures and different filler metals. However, it still operates on the same principle. Brazing copper requires a specific brazing flux to remove oxides at those higher temperatures.

The "Visibly Clean" Trap

The most dangerous pitfall is assuming that because you just sanded or brushed the copper, it's clean enough. The invisible oxide layer begins to re-form almost instantly and accelerates massively the moment you apply heat. Mechanical cleaning is step one; chemical cleaning with flux is the mandatory second step.

Ensuring a Perfect Solder Joint Every Time

Following the correct procedure is the only way to guarantee a strong, reliable, and long-lasting solder joint.

- If your primary focus is plumbing or mechanical joints: First, mechanically clean both the pipe and the fitting until they are bright, then apply a thin, even layer of paste flux before heating.

- If your primary focus is electronics: Use a quality rosin-core solder and consider applying additional liquid or paste flux to the circuit board pads, especially for surface-mount components.

- If you are repairing an old joint: You must completely remove all the old solder, thoroughly re-clean the copper surfaces down to bare metal, and then apply fresh flux before re-soldering.

Skipping flux is not a shortcut; it's a guarantee of failure that undermines the entire purpose of soldering.

Summary Table:

| Key Point | Explanation |

|---|---|

| The Problem | Heat creates a layer of copper oxide that solder cannot bond to. |

| Flux's Role | Chemically cleans the oxide and prevents re-oxidation during heating. |

| Result Without Flux | Solder beads up, creating a weak, brittle joint that will fail. |

| Self-Fluxing Solder? | Still contains flux (e.g., rosin-core); it is not flux-free. |

Achieve Flawless, Reliable Joints with the Right Tools

Understanding the chemistry of soldering is the first step to success. The second is having the right equipment for precise heating and application.

KINTEK specializes in high-quality lab equipment and consumables, serving professionals who demand precision and reliability. Whether you are working on intricate electronics or robust plumbing systems, the right tools make all the difference.

Let us help you perfect your process. Our range of heating solutions and expert support can ensure your projects are built to last.

Contact our experts today to discuss how KINTEK can support your laboratory and technical soldering needs.

Visual Guide

Related Products

- Copper Sulfate Reference Electrode for Laboratory Use

- High Purity Gold Platinum Copper Iron Metal Sheets

- Non Consumable Vacuum Arc Induction Melting Furnace

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the necessity of achieving a high vacuum level of 10^-5 mbar? Ensure Purity in EHEAs Melting.

- How do you sinter tungsten carbide? Master the Process for High-Performance Materials

- How are vacuum removal systems utilized during the synthesis of titanium alloy modification molecules? | KINTEK

- What are the mechanisms of sintering process? Unlock Stronger, Denser Materials

- What are the advantages of using a vacuum drying oven for Ga0.25Zn4.67S5.08? Protect Your Material’s Integrity.

- What is the precaution of furnace? Essential Safety Steps to Protect Operators and Equipment

- Why is a vacuum drying oven required for composite cathodes? Ensure Stability in Solution Infiltration Processes

- What type of furnace is used for metal casting? Choose the Right Furnace for Your Process