Yes, an induction furnace is highly effective for melting iron. In fact, this technology is a cornerstone of modern metallurgy, widely used for melting not only pure iron but also steel and a vast range of iron-based alloys. The process works by using electromagnetic induction to generate intense heat directly within the metal itself, offering a clean, controllable, and efficient melting solution.

The core principle is straightforward: an induction furnace uses a powerful, alternating magnetic field to heat and melt conductive metals like iron. The critical factor is ensuring the specific furnace is rated to reach the high temperatures required for the target metal, which for pure iron is approximately 1538°C (2800°F).

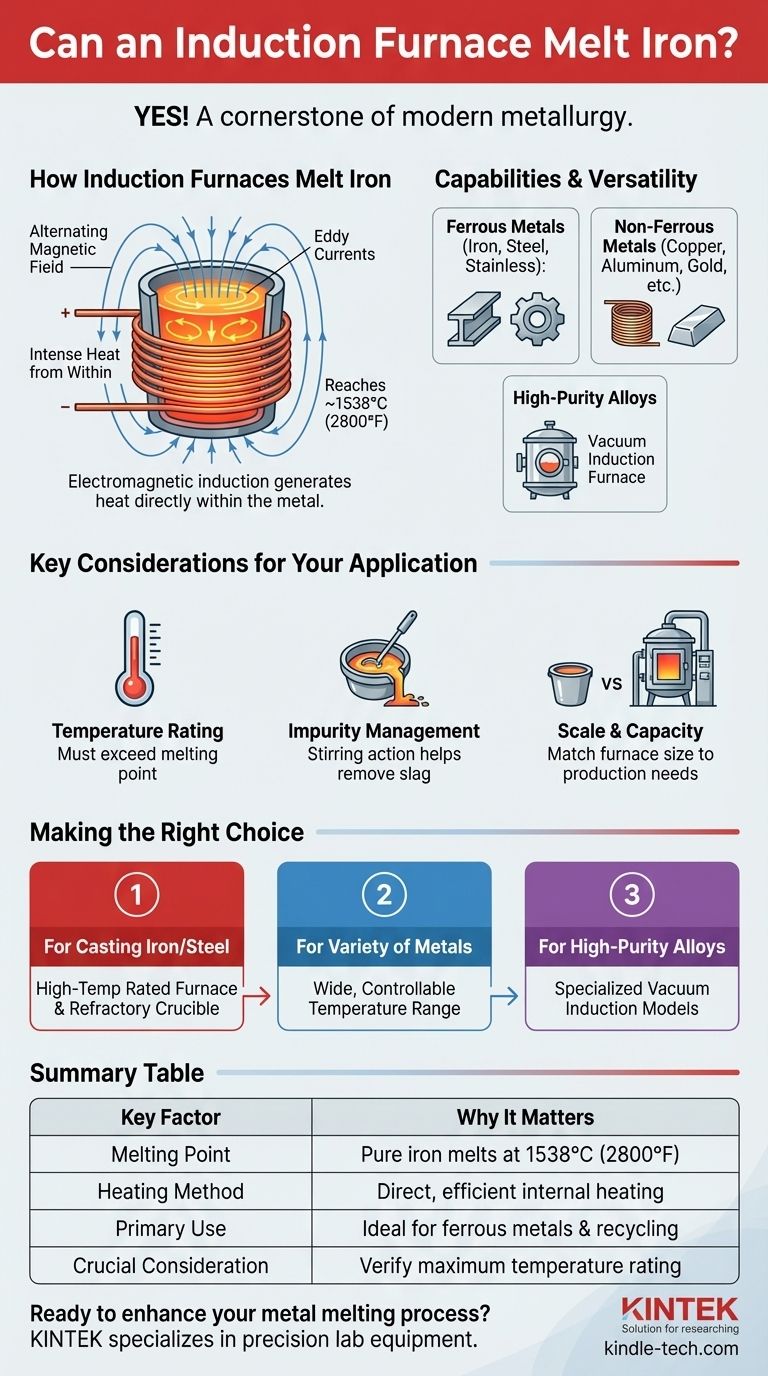

How Induction Furnaces Melt Iron

An induction furnace does not use external flames or heating elements to melt the metal. The heat is generated from within the material, making the process highly efficient.

The Principle of Electromagnetic Induction

An induction furnace uses a water-cooled copper coil through which a powerful alternating electrical current is passed. This current generates a strong, rapidly changing magnetic field around the coil and through the metal placed inside a crucible.

This magnetic field induces powerful secondary electrical currents, called eddy currents, directly within the iron. The natural electrical resistance of the iron causes these eddy currents to generate immense heat, rapidly raising the metal's temperature to its melting point.

Reaching Iron's Melting Point

Pure iron melts at approximately 1538°C (2800°F), while steel, its most common alloy, melts around 1370°C (2500°F). Induction furnaces are specifically designed to generate the energy required to reach and exceed these high temperatures with precision.

The Broader Capabilities of Induction Technology

While exceptionally well-suited for iron, the capabilities of induction furnaces extend to a wide spectrum of materials, making them a versatile tool in foundries and labs.

Ferrous Metals

The primary application for many induction furnaces is melting ferrous metals. This includes pure iron, all grades of steel, and stainless steel. The technology is ideal for recycling scrap metal into high-quality alloys.

Non-Ferrous Metals

Induction technology is equally effective for melting non-ferrous metals, though often with different furnace configurations. This commonly includes materials like copper, aluminum, brass, zinc, gold, and silver.

High-Purity and Specialty Alloys

For metals that react easily with oxygen or nitrogen at high temperatures, a vacuum induction furnace is used. This specialized equipment melts materials like superalloys, nickel, and cobalt in a vacuum to prevent contamination and ensure the final product's purity.

Key Considerations for Your Application

Choosing the right furnace involves more than confirming it can melt a specific metal. Several factors influence the success and efficiency of the operation.

Matching Furnace Power to Metal Type

The most critical factor is the furnace's temperature rating. A furnace designed for melting lower-temperature metals like aluminum or zinc will not have the power or insulation to handle iron or steel safely and efficiently. Always verify the furnace's maximum sustainable temperature.

The Influence of Impurities

The melting process is affected by the presence of impurities, slags, and oxidants. A well-managed process accounts for these factors to ensure the final cast is of high quality. The stirring action created by the magnetic field can actually help mix alloys and bring impurities to the surface to be skimmed off.

Scale and Capacity

The size of the furnace and its crucible must align with your production needs. A small furnace used for precious metals in a lab is fundamentally different from a large industrial furnace designed to melt tons of scrap steel.

Making the Right Choice for Your Goal

To select the appropriate equipment, begin with your end goal in mind.

- If your primary focus is melting pure iron or steel for casting: Ensure the furnace's maximum temperature rating is safely above 1538°C (2800°F) and that its crucible is made from a refractory material suited for these temperatures.

- If your primary focus is melting a variety of different metals: Look for a furnace with a wide, controllable temperature range to efficiently handle everything from aluminum to iron alloys without wasting energy.

- If your primary focus is producing high-purity specialty alloys: A standard induction furnace may not be sufficient; you will need to investigate specialized vacuum induction models to prevent atmospheric contamination.

By matching the furnace's capabilities to the specific properties of your metal, you ensure an efficient, controlled, and successful melting operation.

Summary Table:

| Key Factor | Why It Matters for Melting Iron |

|---|---|

| Melting Point | Pure iron melts at 1538°C (2800°F); furnace must exceed this temperature. |

| Heating Method | Electromagnetic induction heats metal directly from within for high efficiency. |

| Primary Use | Ideal for ferrous metals (iron, steel) and recycling scrap into high-quality alloys. |

| Crucial Consideration | Verify the furnace's maximum temperature rating matches your metal's requirements. |

Ready to enhance your metal melting process?

KINTEK specializes in precision lab equipment and consumables, providing reliable induction furnaces designed for the demanding needs of laboratories and foundries. Whether you're melting iron, steel, or specialized alloys, our solutions offer the control and efficiency you require.

Contact our experts today to find the perfect induction furnace for your specific application and metal melting goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the common operating temperature in a furnace? A Guide to Industrial Heat Treatment Ranges