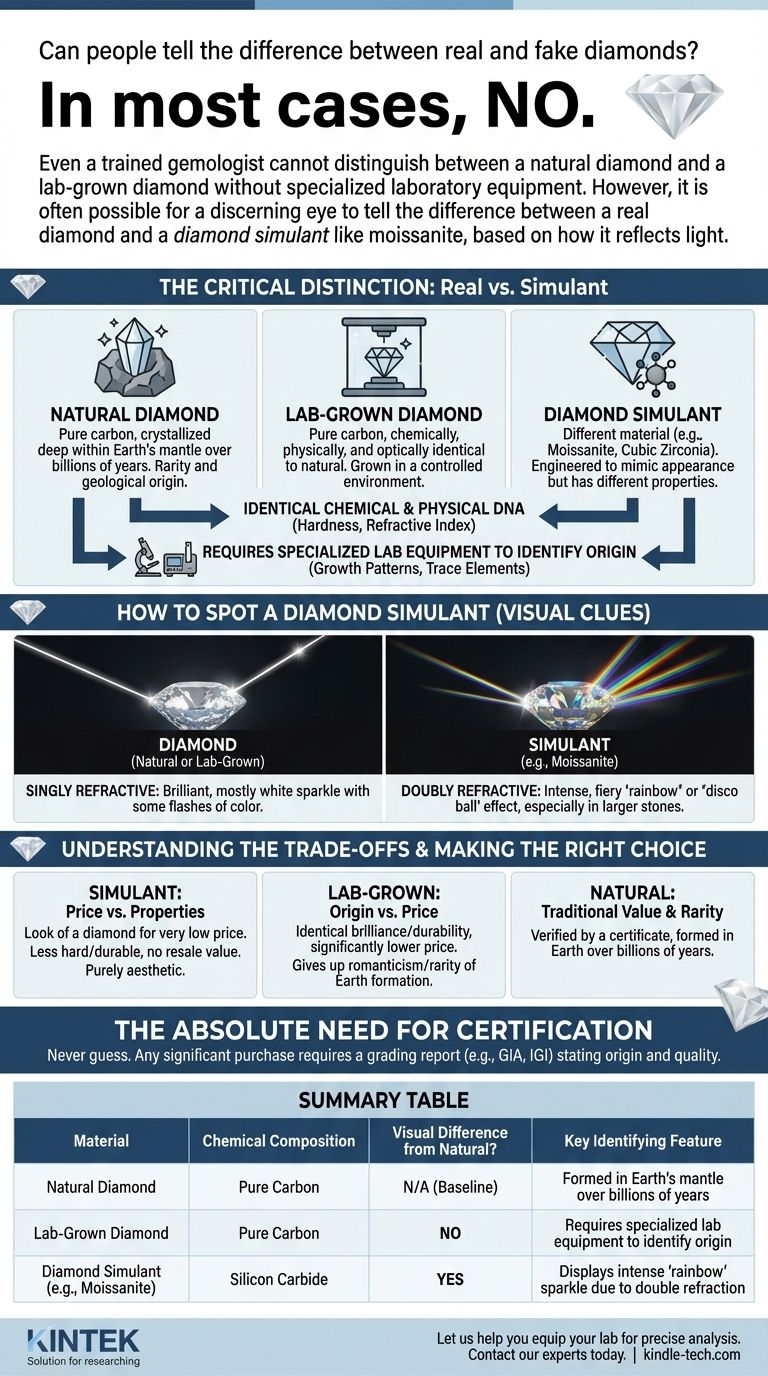

In most cases, no. Even a trained gemologist cannot distinguish between a natural diamond and a lab-grown diamond without specialized laboratory equipment. However, it is often possible for a discerning eye to tell the difference between a real diamond and a diamond simulant like moissanite, based on how it reflects light.

The term "fake diamond" is misleading. The critical distinction is between lab-grown diamonds, which are chemically real diamonds, and diamond simulants, which are entirely different materials designed to look like diamonds. You cannot see the difference in the former, but you often can with the latter.

The Critical Distinction: Real vs. Simulant

To understand what you can and cannot see, you first need to understand the materials involved. The debate isn't just about "real vs. fake," but about three distinct categories.

What is a Natural Diamond?

A natural diamond is composed of pure carbon, crystallized deep within the Earth's mantle over billions of years under immense heat and pressure. Its rarity and geological origin are central to its traditional value.

What is a Lab-Grown Diamond?

A lab-grown diamond is also composed of pure carbon and possesses the exact same chemical, physical, and optical properties as a natural diamond. It is grown in a controlled environment using technologies like CVD (Chemical Vapor Deposition). It is, for all practical purposes, a real diamond.

What is a Diamond Simulant?

A diamond simulant, like moissanite or cubic zirconia, is a different material entirely. It is not carbon. These stones are engineered to mimic the appearance of a diamond but have different physical properties.

Why You Can’t Visually Identify Lab-Grown Diamonds

The inability to visually separate a natural diamond from a lab-grown one is not a matter of training; it's a matter of physics.

Identical Chemical and Physical DNA

Because they are both crystallized carbon, lab-grown and natural diamonds share the same hardness, specific gravity, and refractive index. They bend and reflect light in the exact same way.

The Need for Specialized Equipment

Gemological laboratories identify a diamond's origin by detecting microscopic differences in its growth patterns and trace elements. These are signatures of its formation process—either geologic or industrial—and are completely invisible to the naked eye.

How to Spot a Diamond Simulant

While lab diamonds are visually identical to natural ones, simulants often give themselves away with their distinct optical properties.

The Sparkle Test (Refraction)

This is the most common visual clue. A diamond is singly refractive, which means it produces a brilliant, mostly white sparkle with some flashes of color.

A moissanite, the most popular simulant, is doubly refractive. This property splits light into two rays, creating an intense, fiery "rainbow" or "disco ball" effect. This is especially noticeable in larger stones and under direct light.

Understanding the Trade-offs

Choosing between these stones is not about spotting a fake but about understanding what you value. There is no right or wrong answer, only a series of trade-offs.

The Simulant Trade-off: Price vs. Properties

Simulants offer the look of a diamond for a very low price. However, they are not as hard or durable as a real diamond and hold virtually no resale value. They are a purely aesthetic choice.

The Lab-Grown Trade-off: Origin vs. Price

This is the core debate for most modern buyers. A lab-grown diamond offers identical brilliance and durability to a natural diamond, often at a significantly lower price. The only trade-off is giving up the romanticism and rarity of a stone formed in the Earth.

The Absolute Need for Certification

You should never have to guess a stone's identity. Any significant diamond purchase—whether natural or lab-grown—must come with a grading report from a reputable institution like the GIA or IGI. This certificate will explicitly state the diamond's origin and quality characteristics, removing all ambiguity.

Making the Right Choice for Your Goal

Your decision should be guided by your priorities, not by a fear of being fooled.

- If your primary focus is traditional value and rarity: A natural diamond, verified by a certificate, is the correct choice.

- If your primary focus is getting the largest, highest-quality diamond for your budget: A lab-grown diamond provides the exact same visual and physical performance as a natural one.

- If your primary focus is affordable sparkle for fashion purposes: A simulant like moissanite offers a brilliant look, as long as you understand it is not a diamond.

Ultimately, knowledge and certification are your best tools for making a confident and informed decision.

Summary Table:

| Material | Chemical Composition | Visual Difference from Natural Diamond? | Key Identifying Feature |

|---|---|---|---|

| Natural Diamond | Pure Carbon | N/A (Baseline) | Formed in Earth's mantle over billions of years. |

| Lab-Grown Diamond | Pure Carbon | No | Requires specialized lab equipment to identify origin. |

| Diamond Simulant (e.g., Moissanite) | Silicon Carbide | Yes | Displays intense 'rainbow' sparkle due to double refraction. |

Make an informed decision with confidence. Whether you're a jeweler verifying a stone's authenticity or a researcher analyzing materials, having the right equipment is key. KINTEK specializes in precision lab equipment and consumables, serving the exact needs of gemologists and material scientists. Let us help you equip your lab for precise analysis. Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is MPCVD method? A Guide to High-Purity Diamond Synthesis

- How does MPCVD work? A Guide to Low-Temperature, High-Quality Film Deposition

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis