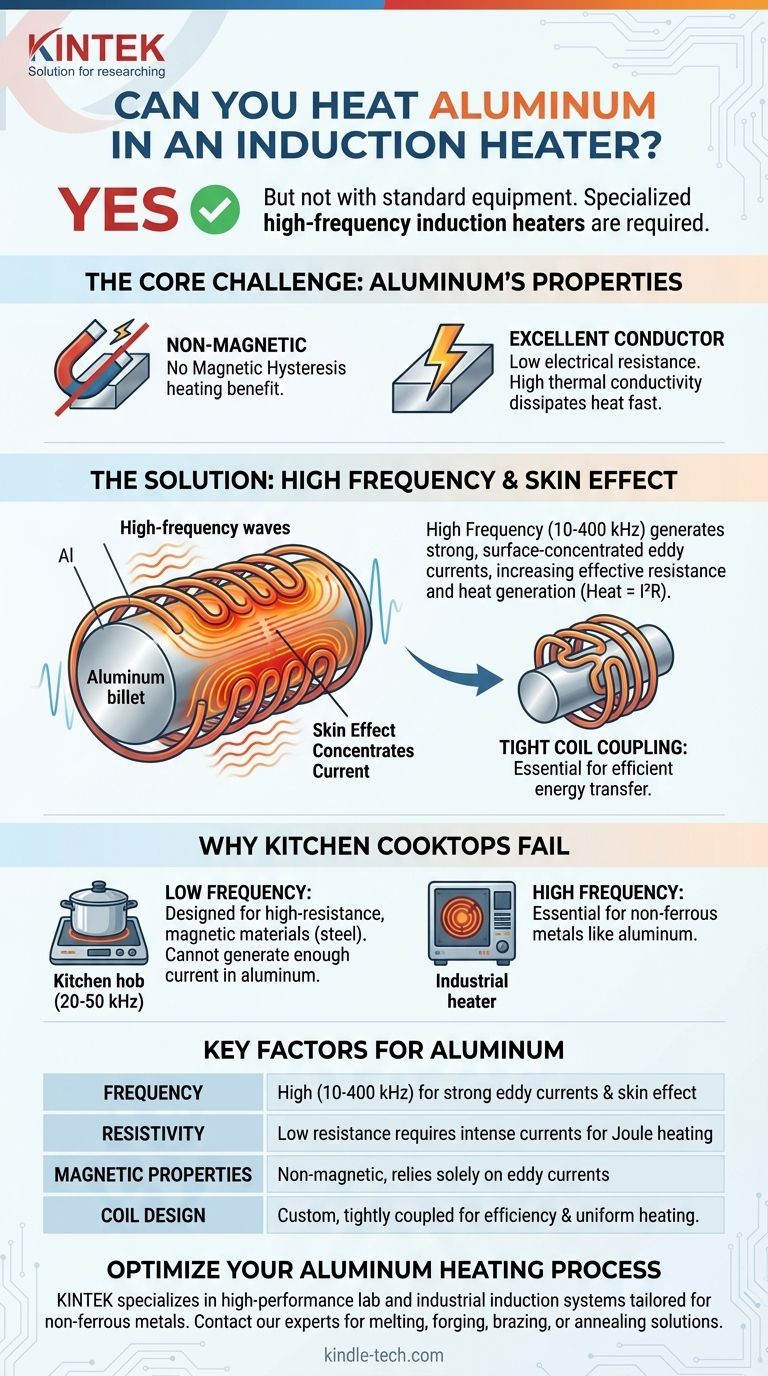

Yes, but not with the equipment you might expect. While a standard kitchen induction cooktop will not heat an aluminum pan, specialized industrial induction heaters can heat and even melt aluminum with remarkable efficiency. The success of heating aluminum via induction hinges entirely on using the correct frequency and power.

The core challenge is that aluminum is non-magnetic and an excellent electrical conductor. To overcome this, you must use a high-frequency induction system that can generate intense eddy currents near the material's surface, producing the necessary heat faster than the aluminum can conduct it away.

How Induction Heating Fundamentally Works

To understand why aluminum is a special case, we first need to review the core principles of induction.

The Role of a Magnetic Field

An induction heater uses a coil of wire through which a high-frequency alternating current (AC) is passed. This creates a powerful and rapidly changing magnetic field in the space around and within the coil.

Generating Heat with Eddy Currents

When a conductive material like aluminum is placed within this magnetic field, the field induces circular electrical currents inside the material. These are known as eddy currents.

The Importance of Resistance

These eddy currents flow through the material's natural electrical resistance. This process generates precise and instantaneous heat directly within the part, a phenomenon described by Joule's first law (Heat = Current² × Resistance).

Why Aluminum Presents a Challenge

The properties that make aluminum a valuable material—its low weight and high conductivity—also make it difficult to heat with common induction systems.

The Problem of Low Resistivity

Aluminum is an excellent conductor of electricity, meaning it has very low electrical resistance. According to the Joule heating formula, if the resistance (R) is very low, you need to generate an enormous amount of current (I) to produce significant heat.

The Absence of Magnetic Hysteresis

For ferromagnetic materials like iron and steel, a secondary heating effect called magnetic hysteresis provides a significant boost, especially at lower temperatures. Because aluminum is non-magnetic (paramagnetic), it gets zero heating benefit from this effect, placing the entire burden on eddy currents.

The Solution: High Frequency and Coil Design

Overcoming aluminum's low resistance requires a specific engineering approach. The key variable is not power alone, but frequency.

Overcoming Low Resistance with Frequency

The strength of the induced eddy currents is directly proportional to the frequency of the magnetic field. By using a high-frequency power source (typically 10 kHz to 400 kHz), we can induce much stronger eddy currents in the aluminum.

Furthermore, higher frequencies cause the currents to concentrate in a thin layer near the surface of the material. This is called the skin effect. Concentrating the current into a smaller cross-sectional area effectively increases the resistance, dramatically increasing the heating effect (Heat = I²R).

Why Your Kitchen Cooktop Fails

Standard induction cooktops operate at a very low frequency (typically 20-50 kHz) and are specifically designed to work with high-resistance, magnetic materials like cast iron or stainless steel. They simply cannot generate a strong enough current in aluminum to produce heat. Many also have sensors that prevent them from activating if they don't detect ferromagnetic cookware.

The Importance of a Well-Coupled Coil

Energy transfer is most efficient when the induction coil is close to the workpiece. This is known as tight coupling. For industrial applications, coils are custom-designed to match the shape of the aluminum part, ensuring maximum efficiency and uniform heating.

Understanding the Trade-offs and Considerations

While effective, using induction to heat aluminum involves specific technical and financial considerations.

Equipment Cost and Complexity

High-frequency induction power supplies are more complex and costly than the low-frequency systems used for steel. The design of the coil and the overall system requires specialized expertise.

High Power Requirements

Aluminum has high thermal conductivity, meaning it dissipates heat very quickly throughout its mass. To reach forging or melting temperatures, the induction system must deliver power very rapidly, overwhelming the material's ability to conduct the heat away from the surface.

Alloy Differences

Different aluminum alloys have slight variations in electrical resistivity. These differences can affect the ideal frequency and power settings needed to achieve a target temperature in a specific amount of time.

Making the Right Choice for Your Goal

Your approach depends entirely on your objective.

- If your primary focus is cooking at home: Do not use pure aluminum pans. Instead, choose induction-ready cookware that has a built-in ferromagnetic base layer.

- If your primary focus is a hobby project like melting small amounts of aluminum: You will need a dedicated, benchtop high-frequency induction furnace designed specifically for non-ferrous metals.

- If your primary focus is an industrial process (forging, brazing, or annealing): You must partner with an induction heating specialist to engineer a system with the correct frequency, power, and coil design for your specific aluminum alloy and part geometry.

Ultimately, heating aluminum with induction is a solved problem in engineering, requiring the right tool for the job.

Summary Table:

| Key Factor | Why It Matters for Aluminum |

|---|---|

| Frequency | High frequency (10-400 kHz) is required to generate strong eddy currents and utilize the skin effect for effective heating. |

| Resistivity | Aluminum's low electrical resistance requires intense currents to generate significant heat via Joule heating. |

| Magnetic Properties | Being non-magnetic, aluminum lacks the hysteresis heating benefit, relying solely on eddy currents. |

| Coil Design | Tightly coupled, custom-shaped coils are essential for efficient energy transfer and uniform heating. |

Ready to heat aluminum efficiently in your lab or production line? KINTEK specializes in high-performance lab equipment, including industrial induction heating systems tailored for non-ferrous metals like aluminum. Our experts will help you select the right high-frequency system and coil design for your specific alloy and application—whether it's for melting, forging, brazing, or annealing. Contact us today to optimize your aluminum heating process with precision and reliability!

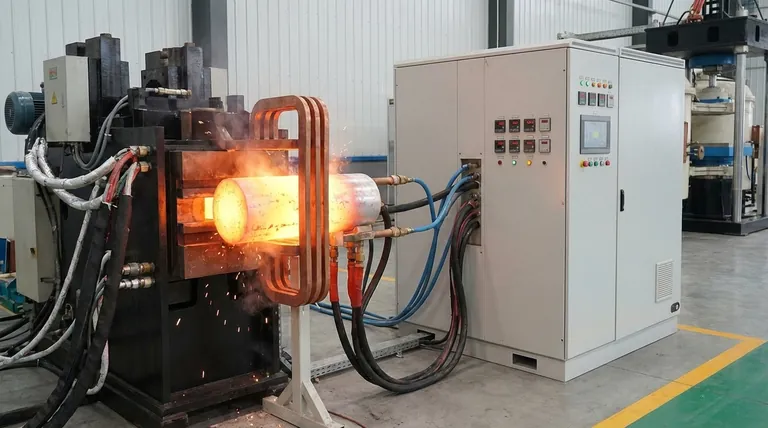

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What process safeguards do induction melting furnaces provide when preparing magnetic alkali borosilicate glass?

- How can we increase the efficiency of induction furnace? Optimize Power, Heat, and Yield for Maximum Performance

- Why high frequency is used in induction furnace? For Precise, Rapid, and Efficient Metal Melting

- How many types of induction furnace are there? Coreless vs. Channel Furnace Guide

- What is the efficiency of an aluminum melting furnace? Unlock High Thermal Performance for Your Foundry

- What are the two types of induction furnace? Coreless vs. Channel for Your Melting Needs

- Why is a vertical induction furnace preferred for heating chromized steel billets? Eliminate Extrusion Surface Defects

- What key environmental conditions does a vacuum induction furnace provide for the synthesis of titanium oxycarbide?