Yes, you can absolutely PVD coat titanium. In fact, it is a very common and highly effective industrial process used to enhance the metal's inherent properties. PVD coatings are applied to titanium to dramatically improve its surface hardness, wear resistance, and coefficient of friction, or to achieve a specific durable color for aesthetic purposes.

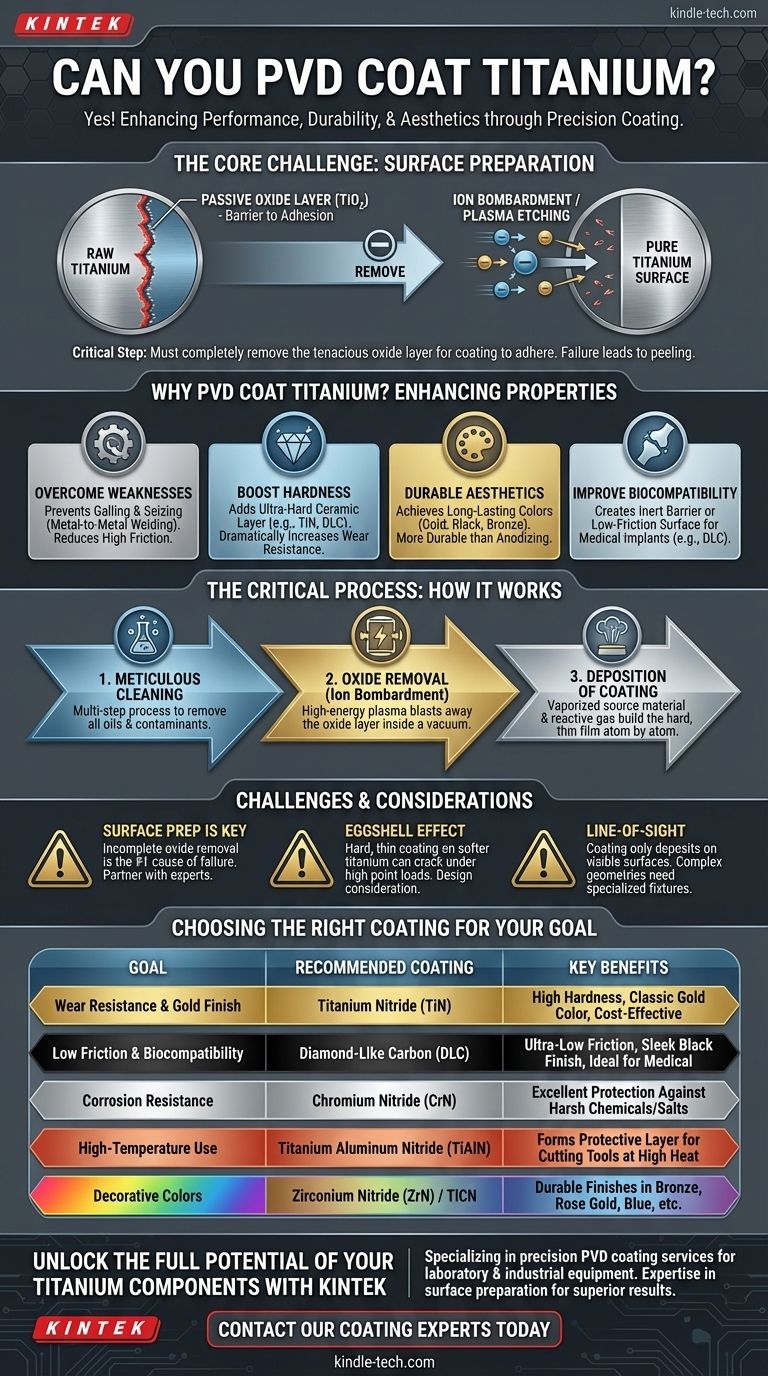

The core challenge of PVD coating titanium is not the process itself, but the meticulous surface preparation required. Titanium naturally forms a tenacious, passive oxide layer that must be completely removed to ensure the coating adheres properly and does not fail prematurely.

Why PVD Coat Titanium? Enhancing a High-Performance Metal

Titanium is known for its excellent strength-to-weight ratio and corrosion resistance. However, it has key weaknesses that PVD coatings are perfectly suited to address.

Overcoming Titanium's Natural Weaknesses

Pure titanium and many of its alloys are relatively soft and have a high coefficient of friction. This makes them prone to galling and seizing, where surfaces under pressure can effectively weld themselves together, causing severe damage. A PVD coating creates a barrier that prevents this direct metal-to-metal contact.

Boosting Surface Hardness and Wear Resistance

The primary reason to PVD coat titanium is to add a thin, extremely hard ceramic layer to the surface. Coatings like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC) are significantly harder than the titanium substrate, dramatically increasing resistance to scratches, abrasion, and wear.

Achieving Durable Aesthetic Finishes

PVD provides a method to apply a wide range of colors to titanium that are far more durable than anodizing or painting. This is highly valued in industries like watchmaking, jewelry, and high-end electronics, where a finish like black, gold, or bronze must withstand daily use.

Improving Biocompatibility for Medical Implants

In medical applications, PVD coatings serve multiple functions. Coatings like DLC can create an ultra-low-friction surface for joint implants, while others can form a chemically inert barrier that enhances the biocompatibility of the device within the human body.

The Critical Process: How PVD on Titanium Works

The success of a PVD coating on titanium is almost entirely dependent on the quality of the preparation and the control of the process.

Step 1: The Foundation of Meticulous Cleaning

This is the most critical stage. The part is subjected to a multi-step cleaning process to remove all oils, greases, and contaminants. Failing to do this will cause the final coating to peel or flake off.

Step 2: Removing the Oxide Layer

After cleaning, the titanium parts are loaded into a vacuum chamber. Before the coating process begins, the parts are subjected to ion bombardment (also known as plasma etching or sputter cleaning). This high-energy process physically blasts away the tough, invisible layer of titanium oxide (TiO₂) that naturally forms on the surface. Applying a coating over this oxide layer is like painting on a dusty wall—it simply won't stick.

Step 3: Deposition of the Coating

Once the pure titanium surface is exposed, the coating process begins. A solid source material (e.g., a block of titanium for a TiN coating) is vaporized by an electric arc or a sputtering target. This vapor travels through the vacuum and a reactive gas (like nitrogen) and deposits onto the titanium part, building a new, dense, and highly-adherent film atom by atom.

Understanding the Trade-offs and Challenges

While highly effective, the process is not without its considerations. Understanding them is key to a successful outcome.

The Absolute Necessity of Surface Prep

The single biggest point of failure is poor adhesion due to an incomplete removal of the native oxide layer. Any shortcut or error in the cleaning and ion etching stage will compromise the entire coating. Always partner with a coater who has specific experience with titanium.

The "Eggshell Effect"

A PVD coating is extremely hard, but it is also very thin (typically 1-5 microns). If a hard, thin coating is applied to a softer substrate, a high point load can cause the underlying titanium to deform, cracking the coating like an eggshell. This is a design consideration; the substrate must be able to support the coating under expected loads.

Line-of-Sight Application

Most PVD processes are "line-of-sight," meaning the coating can only deposit on surfaces that the vaporized source can "see." Deep internal bores or complex, hidden geometries may not receive an even coating without specialized fixtures and part rotation within the chamber.

Choosing the Right Coating for Your Application

The best coating depends entirely on your goal. Below are the most common options for titanium substrates.

- If your primary focus is wear resistance and a classic gold look: Titanium Nitride (TiN) is the industry standard, offering a great balance of hardness, durability, and cost.

- If your primary focus is maximum friction reduction and biocompatibility: Diamond-Like Carbon (DLC) provides an exceptionally low coefficient of friction and a sleek black finish, making it a premium choice for medical implants and high-performance components.

- If your primary focus is corrosion resistance and a silver finish: Chromium Nitride (CrN) offers superior corrosion protection compared to TiN and is an excellent choice for parts exposed to harsh chemicals or marine environments.

- If your primary focus is high-heat applications: Titanium Aluminum Nitride (TiAlN) forms an aluminum oxide layer at high temperatures, protecting the coating and making it ideal for cutting tools that will operate at high speeds.

- If your primary focus is a specific decorative color: A wide range of coatings, often based on Zirconium Nitride (ZrN) or Titanium Carbonitride (TiCN), can produce durable finishes in bronze, graphite, blue, and rose gold.

By selecting the right PVD coating, you can transform a titanium component, unlocking a level of performance and durability that the raw material alone cannot achieve.

Summary Table:

| Goal | Recommended PVD Coating | Key Benefits |

|---|---|---|

| Wear Resistance & Gold Finish | Titanium Nitride (TiN) | High hardness, classic gold color, cost-effective |

| Low Friction & Biocompatibility | Diamond-Like Carbon (DLC) | Ultra-low friction, sleek black finish, ideal for medical |

| Corrosion Resistance | Chromium Nitride (CrN) | Excellent protection against harsh chemicals/salts |

| High-Temperature Use | Titanium Aluminum Nitride (TiAlN) | Forms protective layer for cutting tools at high heat |

| Decorative Colors | Zirconium Nitride (ZrN) / TiCN | Durable finishes in bronze, rose gold, blue, etc. |

Ready to unlock the full potential of your titanium components?

At KINTEK, we specialize in precision PVD coating services for laboratory and industrial equipment. Our expertise ensures meticulous surface preparation and the correct coating application to deliver superior hardness, wear resistance, and stunning, durable finishes for your titanium parts.

Contact our coating experts today to discuss how we can enhance your project's performance and longevity.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films