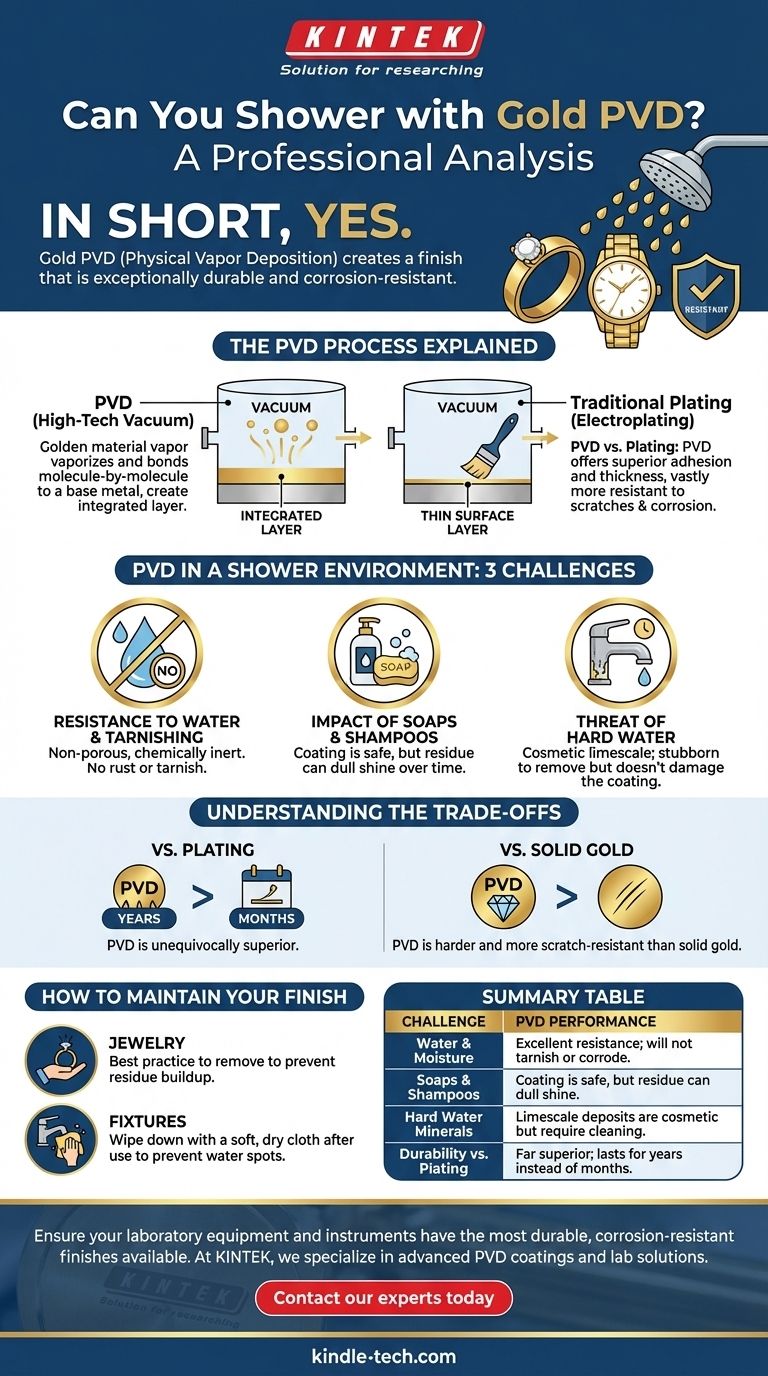

In short, yes, you can shower with items that have a gold PVD coating. The Physical Vapor Deposition (PVD) process creates a finish that is exceptionally durable, corrosion-resistant, and far superior to traditional gold plating. It is specifically engineered to withstand exposure to moisture and daily use without tarnishing or fading.

While gold PVD is highly resistant to water, the primary long-term threat to its appearance isn't the water itself, but the soap scum, hard water minerals, and chemicals that accompany it. The coating will endure, but its shine can be dulled by residue.

What "Gold PVD" Actually Means

To understand its durability, you must first understand what PVD is. It's a modern coating process that is fundamentally different from traditional electroplating.

The PVD Process Explained

Physical Vapor Deposition (PVD) is a process conducted in a high-tech vacuum chamber. A solid material, often a highly durable ceramic like titanium nitride, is vaporized into a plasma of atoms.

This vapor is then bonded molecule by molecule onto the base metal (such as stainless steel or brass). A layer of real gold can be added during this process, creating a finish that is fused to the object rather than simply painted on.

PVD vs. Traditional Gold Plating

The key difference is adhesion and thickness. Traditional gold plating applies a very thin layer of gold that is prone to chipping, flaking, and wearing off, especially with friction and chemical exposure.

PVD, by contrast, creates a much harder and denser layer that is an integral part of the surface. This makes it vastly more resistant to scratches and corrosion.

PVD's Performance in a Shower Environment

A shower introduces three main challenges: constant moisture, chemical agents, and mineral deposits. Here is how a gold PVD finish holds up against each.

Resistance to Water and Tarnishing

The PVD coating is non-porous and chemically inert. This means water alone cannot penetrate the finish to cause rust or corrosion on the base metal.

Furthermore, unlike sterling silver or brass, the surface itself will not tarnish or oxidize when exposed to water and air.

The Impact of Soaps and Shampoos

While the PVD coating is highly resistant to most chemicals found in soaps, shampoos, and body washes, these products can leave behind a dull film or residue.

Over time, this soap scum can build up, obscuring the luster of the gold finish. While this doesn't damage the coating itself, it diminishes its aesthetic appeal and requires cleaning to restore.

The Threat of Hard Water

For bathroom fixtures, the biggest concern is hard water. The minerals in hard water, like calcium and magnesium, can leave chalky white deposits (limescale) on the surface as water evaporates.

These deposits are purely cosmetic but can be stubborn to remove. Cleaning them often requires acidic cleaners, which, with repeated use over many years, could potentially affect the finish.

Understanding the Trade-offs

Choosing a finish always involves balancing cost, appearance, and durability. PVD represents a specific point on this spectrum.

The Advantage Over Plating

For any item exposed to moisture, from a watch to a showerhead, PVD is unequivocally superior to gold plating. A plated item will likely see its finish degrade in a matter of months with daily showering, while a PVD item will last for many years.

The Difference from Solid Gold

Solid gold is the benchmark for preciousness but not necessarily for durability. Gold is a very soft metal, making it susceptible to scratches and dents.

PVD coatings, often incorporating materials like titanium, are significantly harder than solid gold, offering far greater scratch resistance. The trade-off is that PVD is a coating and not the bulk material.

How to Maintain Your Gold PVD Finish

Proper care is not about protecting the finish from failure, but about maintaining its brilliant appearance over the long term.

-

If your primary concern is jewelry: It is best practice to remove PVD jewelry before showering. This prevents soap scum and residue buildup, ensuring the piece retains its maximum shine with minimal cleaning.

-

If your primary concern is bathroom or kitchen fixtures: Simply wipe the fixtures down with a soft, dry microfiber cloth after use. This small step prevents water spots and mineral buildup, dramatically reducing the need for more intensive cleaning later.

By understanding how gold PVD truly works, you can ensure your items remain durable and beautiful for years.

Summary Table:

| Challenge | Gold PVD's Performance |

|---|---|

| Water & Moisture | Excellent resistance; will not tarnish or corrode. |

| Soaps & Shampoos | Coating is safe, but residue can dull shine. |

| Hard Water Minerals | Limescale deposits are cosmetic but require cleaning. |

| Durability vs. Plating | Far superior; lasts for years instead of months. |

Ensure your laboratory equipment and instruments have the most durable, corrosion-resistant finishes available. At KINTEK, we specialize in advanced PVD coatings and lab equipment solutions designed to withstand demanding environments. Whether you need coated components for analytical instruments or durable finishes for lab tools, our expertise ensures long-lasting performance and aesthetic appeal.

Contact our experts today to discuss how our PVD coatings and lab solutions can enhance the durability and reliability of your equipment.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer