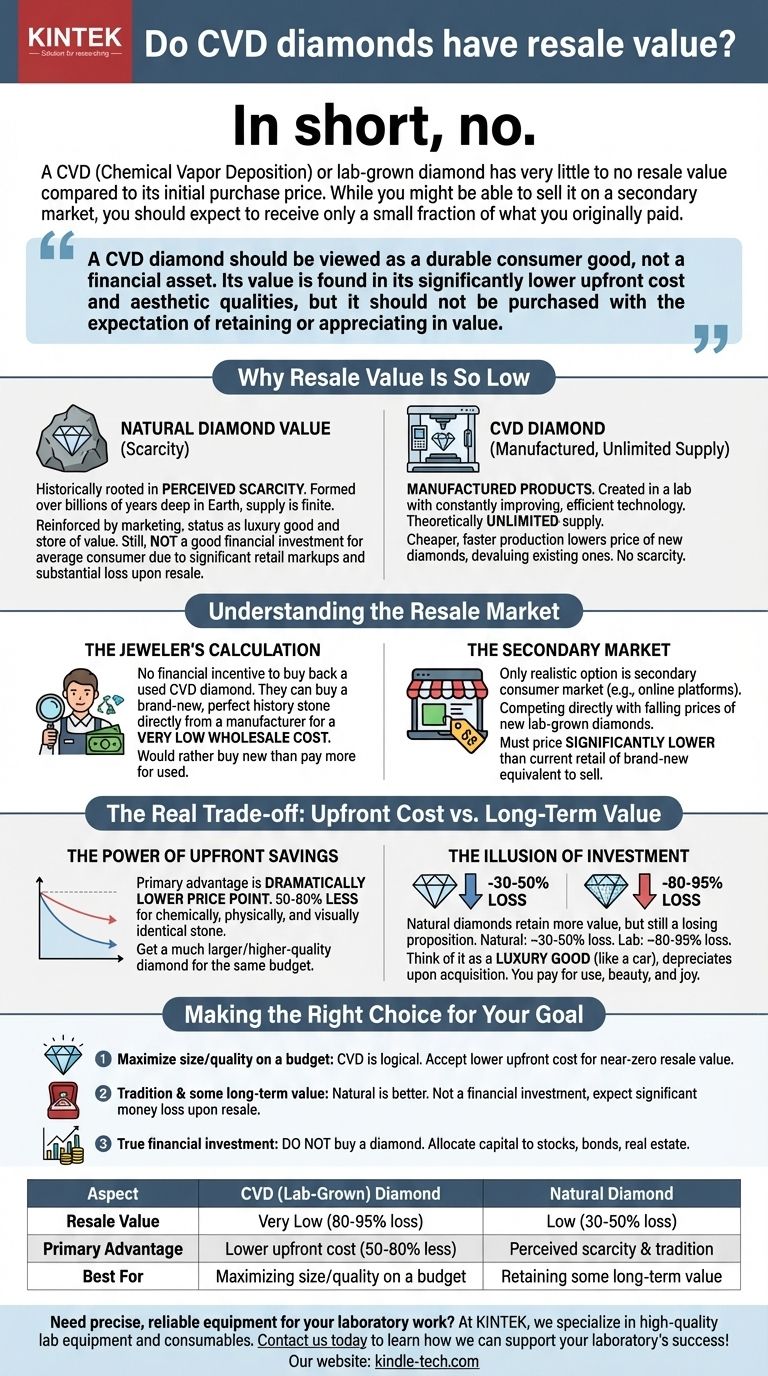

In short, no. A CVD (Chemical Vapor Deposition) or lab-grown diamond has very little to no resale value compared to its initial purchase price. While you might be able to sell it on a secondary market, you should expect to receive only a small fraction of what you originally paid.

A CVD diamond should be viewed as a durable consumer good, not a financial asset. Its value is found in its significantly lower upfront cost and aesthetic qualities, but it should not be purchased with the expectation of retaining or appreciating in value.

Why Resale Value Is So Low

To understand the resale market for CVD diamonds, we must first understand what gives any diamond its value. The equation is different for natural and lab-grown stones.

The Foundation of Natural Diamond Value

The value of a natural diamond is historically rooted in its perceived scarcity. Formed over billions of years deep within the Earth, the supply is finite. This narrative, heavily reinforced by marketing, underpins its status as a luxury good and a store of value.

Even so, it's crucial to know that most natural diamonds are not a good financial investment for the average consumer. The retail price you pay includes significant markups, and you will almost always sell it for a substantial loss.

The Manufacturing Reality of CVD Diamonds

CVD diamonds, by contrast, are manufactured products. They are created in a lab using technology that is constantly improving and becoming more efficient.

This means the supply is theoretically unlimited. As production becomes cheaper and faster, the price of new CVD diamonds falls, which in turn pushes down the value of all existing CVD diamonds on the market. There is no scarcity to prop up their long-term value.

Understanding the Resale Market

When you try to sell a used diamond, you are competing with the wholesale market. This is where the difference between natural and lab-grown becomes stark.

The Jeweler's Calculation

A jeweler has no financial incentive to buy back a used CVD diamond for a high price. They can purchase a brand-new, identical (or better) CVD diamond directly from a manufacturer for a very low wholesale cost.

Essentially, they would rather buy a new stone with a perfect history than pay more for a used one. This dynamic effectively removes the primary buy-back channel that exists for natural diamonds.

The Secondary Market

Your only realistic option for reselling a CVD diamond is the secondary consumer market, such as online platforms. Here, you are competing directly with the falling prices of new lab-grown diamonds.

A potential buyer will always compare your used stone to a new one from an online retailer. To make a sale, you will have to price your diamond significantly lower than the current retail price of a brand-new equivalent.

The Real Trade-off: Upfront Cost vs. Long-Term Value

The decision between a CVD and a natural diamond is not about which one is a better "investment"—it's about understanding what you are paying for.

The Power of Upfront Savings

The primary advantage of a CVD diamond is its dramatically lower price point. For the same budget, you can acquire a much larger and higher-quality lab-grown diamond than a natural one.

This is not a small difference. You are often paying 50-80% less for a stone that is chemically, physically, and visually identical to its natural counterpart.

The Illusion of Investment

While a natural diamond retains more of its value than a lab diamond, it is still a losing proposition financially. You might lose 30-50% of the retail price when you resell a natural diamond. With a lab diamond, you might lose 80-95%.

The key is to frame the purchase correctly. Think of a diamond not as an asset like gold or stocks, but as a luxury good, much like a car. It depreciates the moment you acquire it, and you are paying for its use, beauty, and the joy it brings.

Making the Right Choice for Your Goal

Approach this decision by clarifying your primary objective.

- If your primary focus is maximizing the size and quality of the stone for your budget: A CVD diamond is the logical choice, accepting that the money you "save" upfront is the trade-off for near-zero resale value.

- If your primary focus is tradition and retaining some long-term value: A natural diamond is the better option, but you must go into it understanding that it is not a financial investment and you will still lose significant money upon resale.

- If your primary focus is making a true financial investment: Do not buy a diamond of any kind. Your capital is far better allocated to traditional assets like stocks, bonds, or real estate.

Ultimately, the best choice is the one that aligns with your personal values and budget, free from the myth of your jewelry as a financial asset.

Summary Table:

| Aspect | CVD (Lab-Grown) Diamond | Natural Diamond |

|---|---|---|

| Resale Value | Very Low (80-95% loss) | Low (30-50% loss) |

| Primary Advantage | Lower upfront cost (50-80% less) | Perceived scarcity & tradition |

| Best For | Maximizing size/quality on a budget | Retaining some long-term value |

Need precise, reliable equipment for your laboratory work? At KINTEK, we specialize in high-quality lab equipment and consumables that deliver consistent performance and value. Whether you're in research, quality control, or production, our solutions are designed to meet your exact needs. Contact us today to learn how we can support your laboratory's success!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the future value of lab grown diamond? Understanding Its Depreciating Financial Worth

- What is the future of CVD diamond? Unlocking Next-Gen Electronics & Thermal Management

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained

- What are the common sources of contamination during CVD diamond growth? Improve Purity and Quality Control