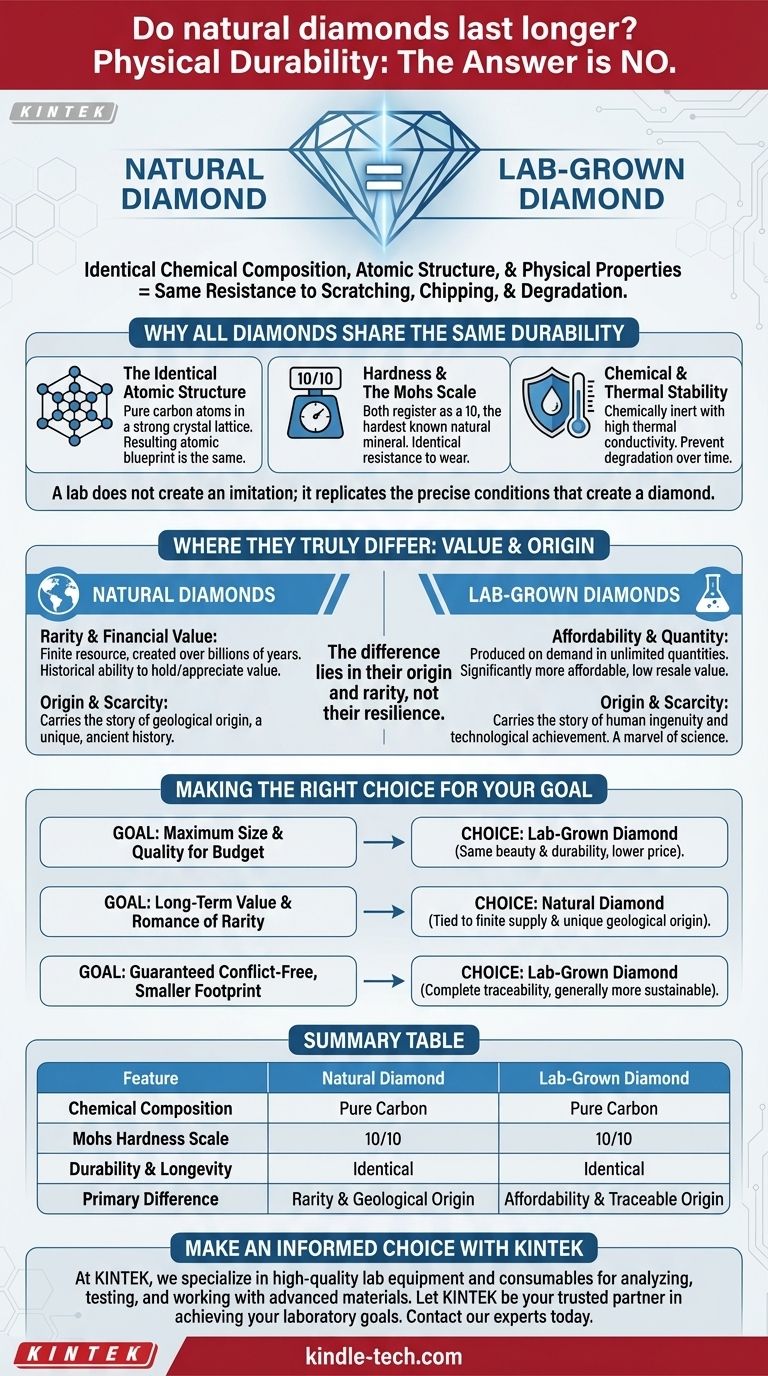

In terms of physical durability, the answer is no. A natural diamond does not last longer than a lab-grown diamond. Because both are identical in their chemical composition, atomic structure, and physical properties, their resistance to scratching, chipping, and degradation is exactly the same. The difference between them lies in their origin and rarity, not their resilience.

The question of whether a natural diamond "lasts longer" confuses its ancient origin with its inherent durability. Both natural and lab-grown diamonds are structurally identical forms of crystallized carbon, granting them the same exceptional hardness and longevity.

Why All Diamonds Share the Same Durability

The longevity of a diamond is dictated by its fundamental material properties. Since lab-grown and natural diamonds are the same material, they are equally durable.

The Identical Atomic Structure

At a molecular level, a diamond is pure carbon atoms arranged in an incredibly strong and rigid crystal lattice. This specific atomic bond is what gives a diamond its extraordinary properties.

Whether formed over billions of years in the Earth or over weeks in a controlled laboratory environment, the resulting atomic blueprint is the same. A lab does not create an imitation; it replicates the precise conditions that create a diamond.

Hardness and the Mohs Scale

A material's resistance to scratching is measured on the Mohs scale of hardness. Diamond is famous for being a 10 out of 10 on this scale, making it the hardest known natural mineral.

Both natural and lab-grown diamonds register as a 10 on the Mohs scale. This means that for all practical purposes, their ability to withstand daily wear and resist surface damage is identical.

Chemical and Thermal Stability

Durability isn't just about hardness. Diamonds are also chemically inert, meaning they don't react with common chemicals, and they have extremely high thermal conductivity.

These properties, which prevent degradation over time, are a direct result of the diamond's carbon structure. As such, they are shared equally by both natural and lab-grown stones. The immense age of a natural diamond is simply proof of this inherent stability—a stability that a lab-grown diamond shares by virtue of being the same material.

Where Natural and Lab Diamonds Truly Differ

While their physical longevity is identical, their value proposition and market characteristics are fundamentally different. Understanding this distinction is key to making an informed decision.

Rarity and Financial Value

Natural diamonds are a finite resource created by nature over billions of years. Their rarity is a primary driver of their cost and their historical ability to hold or appreciate in value.

Lab-grown diamonds can be produced on demand in virtually unlimited quantities. This makes them significantly more affordable but also means they are not considered a rare asset and typically have very low to no resale value.

Origin and Scarcity

The core difference is the story. A natural diamond carries the story of its geological origin, a unique history stretching back millions or billions of years.

A lab-grown diamond carries the story of human ingenuity and technological achievement. It is a marvel of science, perfectly replicating a natural process. Neither story is inherently "better," but they appeal to different values.

Making the Right Choice for Your Goal

Your decision should not be based on a false premise of durability. Instead, focus on which diamond's characteristics align with your primary objective.

- If your primary focus is maximum size and quality for your budget: A lab-grown diamond offers the exact same visual beauty and physical durability as a natural one at a substantially lower price point.

- If your primary focus is long-term value and the romance of rarity: A natural diamond is the only choice, as its value is tied to its finite supply and unique geological origin.

- If your primary focus is a guaranteed conflict-free origin with a smaller environmental footprint: A lab-grown diamond provides complete traceability and is generally considered a more sustainable option.

Ultimately, the choice is not about which diamond will last longer, but about which origin story and value proposition aligns with your personal goals.

Summary Table:

| Feature | Natural Diamond | Lab-Grown Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon | Pure Carbon |

| Mohs Hardness Scale | 10/10 | 10/10 |

| Durability & Longevity | Identical | Identical |

| Primary Difference | Rarity & Geological Origin | Affordability & Traceable Origin |

Make an Informed Choice with KINTEK

Whether you're researching materials for industrial applications or selecting equipment for your lab, understanding the fundamental properties of materials like diamonds is crucial. At KINTEK, we specialize in providing high-quality lab equipment and consumables that help you analyze, test, and work with advanced materials accurately and efficiently.

Our expertise supports researchers, gemologists, and engineers in making precise, data-driven decisions. Let KINTEK be your trusted partner in achieving your laboratory goals.

Contact our experts today to discuss your specific needs and discover the right solutions for your project.

Visual Guide

Related Products

- CVD Diamond Domes for Industrial and Scientific Applications

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the temperature of a plasma reactor? Harnessing Stellar Power on Earth

- Are CVD diamonds real diamonds? Unveiling the Truth About Lab-Grown vs. Mined Diamonds

- What is the quality of CVD diamonds? Exceptional Brilliance from a Controlled Lab Process

- Are artificial diamonds as strong as natural diamonds? Discover the Truth About Lab-Grown Diamond Durability

- How does microwave generate plasma? Unlocking the Physics of Energy Concentration

- What is the CVD process diamond? A Guide to Lab-Grown Diamonds for Industrial Use

- What pressure is needed for chemical vapor deposition of diamonds? Master the Low-Pressure 'Sweet Spot'

- Can diamond be made artificially? Yes, with Identical Quality to Natural Diamonds