Yes, while exceptionally durable, all PVD coatings can and eventually will wear off. However, Physical Vapor Deposition (PVD) is not a paint or simple plating; it is a high-tech vacuum deposition process that bonds a thin film of ceramic material to a substrate on a molecular level. This results in a finish that is vastly more resistant to scratches, friction, and environmental factors than virtually any traditional coating method.

The question is not if PVD coating wears off, but how and when. Its extreme hardness means it resists the vast majority of everyday scratches, but consistent, abrasive friction against harder or equally hard materials will eventually cause it to wear down, typically on sharp edges and high-contact points.

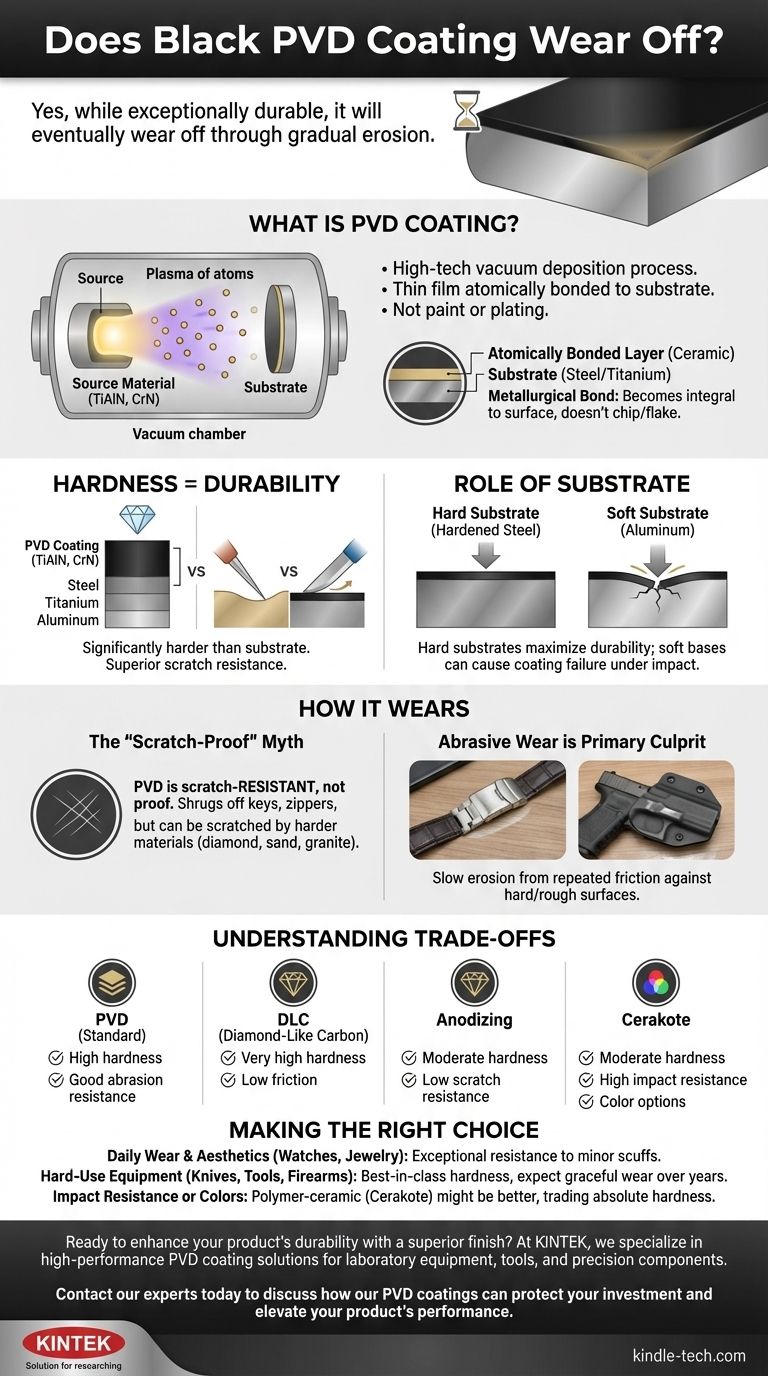

What Is PVD Coating?

To understand how PVD wears, you must first understand what it is. It is fundamentally different from paint, powder coating, or traditional electroplating.

A Thin Film, Atomically Bonded

The PVD process takes place in a high-vacuum chamber where a solid material (often a ceramic like titanium nitride) is vaporized into a plasma of atoms. An electrical voltage then accelerates these atoms toward the object being coated, where they embed themselves and form a thin, dense, and atomically bonded layer.

This bond is metallurgical, meaning the coating becomes an integral part of the surface rather than just sitting on top of it. This is why PVD coatings don't typically chip or flake off like paint.

Hardness Is the Key to Durability

The primary benefit of PVD is its incredible hardness. Materials used for black PVD, such as Titanium Aluminum Nitride (TiAlN) or Chromium Nitride (CrN), are significantly harder than the steel, titanium, or aluminum substrates they coat.

This hardness is what provides its signature scratch resistance. A softer material cannot easily scratch a harder one.

The Role of the Substrate

The material underneath the PVD is critical. If a soft base metal like aluminum is dented by an impact, the very hard but thin PVD layer cannot stretch with the deformation. In these cases, the coating can crack or be compromised.

For maximum durability, PVD is best applied to hard substrates like hardened steel or titanium that resist denting themselves.

How PVD Coating Actually Wears Down

Wear on a PVD coating is a gradual process of erosion, not a sudden failure. It is almost always caused by specific types of mechanical stress.

The Myth of "Scratch-Proof"

No material is truly "scratch-proof." PVD is highly scratch-resistant. This means it will shrug off contact with keys, zippers, wood, and most everyday objects.

However, if you drag it against a material of similar or greater hardness—such as diamond, sapphire, sand (silica), or even the corner of a granite countertop—it can be scratched.

Abrasive Wear Is the Primary Culprit

The most common cause of wear is abrasive friction. This is a slow erosion that happens from repeated rubbing against a hard or rough surface.

On a watch, this often appears on the clasp from rubbing against a desk. On a firearm, it appears on the edges of the slide from being drawn from a hard Kydex holster. This wear looks like a subtle fading or polishing of the high-contact points, eventually revealing the silver-toned metal beneath.

Understanding the Trade-offs

PVD is a top-tier coating, but it exists in a landscape of other options. Understanding its position helps clarify its value.

PVD vs. DLC (Diamond-Like Carbon)

DLC is a specific, premium category of PVD coating that incorporates carbon in an amorphous, diamond-like structure. It is generally harder and has a lower coefficient of friction than standard titanium-based PVD coatings. Think of DLC as the highest-performance version of PVD.

PVD vs. Anodizing

Anodizing is an electrochemical process used only on aluminum. While it can be decorative, the resulting layer is significantly softer and thinner than a PVD coating and scratches very easily in comparison.

PVD vs. Cerakote

Cerakote is a ceramic-polymer spray-on coating that is oven-cured. It is exceptionally tough and offers superior corrosion resistance and a vast array of colors. However, PVD is a fundamentally harder surface. Cerakote will wear from abrasion more quickly than PVD, though it may handle impacts without chipping due to its polymer content.

The Quality of Application Matters Most

A PVD coating's longevity is directly tied to the quality of its application. Factors like surface preparation, chamber temperature, vacuum purity, and process control are critical. A cheap, poorly applied PVD finish will fail much faster than one from a reputable source that has perfected its process.

Making the Right Choice for Your Goal

Whether PVD is the correct choice depends entirely on your performance expectations and application.

- If your primary focus is daily wear and aesthetics (watches, jewelry): PVD offers exceptional resistance to the minor scuffs of daily life, far outlasting traditional polishing, plating, or paint.

- If your primary focus is hard-use equipment (knives, tools, firearms): PVD provides best-in-class hardness and abrasion resistance, but you should expect graceful wear on high-friction points over years of heavy use.

- If your primary focus is impact resistance or unique colors: A high-quality polymer-ceramic coating like Cerakote might be a more suitable choice, though you will be trading absolute surface hardness.

Ultimately, choosing PVD is an investment in a high-performance finish that provides superior wear resistance for a longer lifespan.

Summary Table:

| Factor | Impact on PVD Coating Wear |

|---|---|

| Coating Hardness | Extremely high hardness (e.g., TiAlN, CrN) provides superior scratch and abrasion resistance. |

| Bonding Method | Atomic-level metallurgical bond prevents chipping and flaking; wear is a gradual erosion. |

| Primary Wear Cause | Abrasive friction against harder or equally hard materials (e.g., sand, granite). |

| Common Wear Areas | High-contact points and sharp edges (e.g., watch clasps, firearm slides). |

| Substrate Material | Hard substrates (hardened steel, titanium) maximize durability; soft substrates can lead to cracking on impact. |

Ready to enhance your product's durability with a superior finish?

At KINTEK, we specialize in high-performance PVD coating solutions for laboratory equipment, tools, and precision components. Our advanced coating processes ensure maximum wear resistance and longevity for your critical applications.

Contact our experts today to discuss how our PVD coatings can protect your investment and elevate your product's performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer