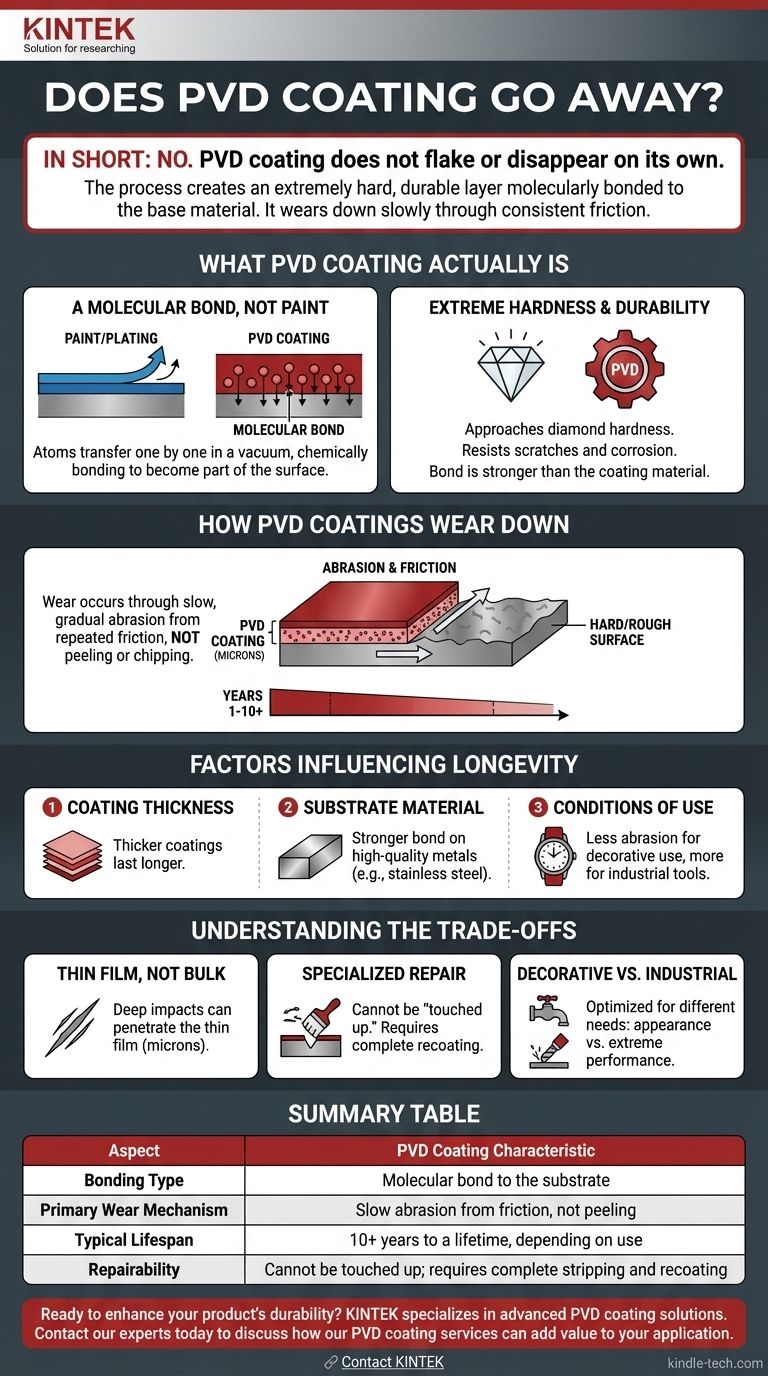

In short, PVD coating does not flake off or disappear on its own. The process creates an extremely hard, durable layer that is molecularly bonded to the base material. However, like any surface, it is not indestructible and can be gradually worn down over a very long period through consistent friction and abrasion.

The core principle to understand is that PVD coatings fail by slow abrasion, not by peeling or chipping. Their lifespan is less a matter of time and more a function of how much physical wear and tear they are subjected to.

What PVD Coating Actually Is

Physical Vapor Deposition (PVD) is a sophisticated vacuum coating process, not a type of paint or plating. Understanding this distinction is key to understanding its durability.

A Molecular Bond, Not a Layer of Paint

The PVD process transfers a metal or ceramic material one atom at a time. In a high-temperature vacuum chamber, a solid source material is vaporized into a plasma and then deposited onto the target object, known as the substrate.

This creates a thin, dense film that is chemically and physically bonded to the surface of the object itself. It isn't just sitting on top; it becomes an integral part of the surface.

Extreme Hardness and Durability

The resulting coating is incredibly hard, in many cases approaching the hardness of a diamond. This is why PVD-coated items are exceptionally resistant to scratches and corrosion.

The coating won't fall off on its own because its bond to the substrate is stronger than the coating material itself.

How PVD Coatings Wear Down

While PVD coatings are exceptionally tough, they are not invincible. Wear occurs through physical interaction, not chemical breakdown or aging.

The Role of Abrasion and Friction

The primary mechanism of wear is abrasion. This happens when the coated surface repeatedly rubs against other hard or rough surfaces.

Over many years, this constant friction can slowly wear away the microscopic layers of the coating, eventually exposing the substrate underneath. The process is slow and gradual, not a sudden failure.

Factors Influencing Longevity

The lifespan of a PVD coating can range from ten years to a lifetime, depending entirely on several key factors:

- Coating Thickness: A thicker coating will naturally take longer to wear through.

- Substrate Material: The bond is strongest on high-quality metals like stainless steel or titanium.

- Conditions of Use: A PVD-coated watch case will face far less abrasion than a PVD-coated drill bit used daily.

Understanding the Trade-offs

PVD offers exceptional performance, but it's important to recognize its practical limitations.

It's a Thin Film, Not Bulk Material

PVD coatings are measured in microns (thousandths of a millimeter). While extremely hard, a deep scratch or a significant impact from a sharp object can penetrate the thin film and expose the base metal underneath.

Repair Is a Specialized Process

You cannot "touch up" a worn or damaged PVD coating. Restoring the surface requires the part to be professionally stripped and then completely recoated in a PVD chamber, which is often impractical or expensive for consumer goods.

Decorative vs. Industrial Coatings

The PVD coatings used on consumer products like watches or faucets are optimized for appearance and moderate wear resistance. Industrial PVD coatings, used on cutting tools, are engineered for extreme performance and may be thicker or made of different materials.

Making the Right Choice for Your Goal

- If your primary focus is avoiding chipping or flaking: PVD is a superior choice over traditional plating or painting, as its molecular bond prevents this type of failure.

- If your primary focus is decorative longevity (e.g., watches, jewelry): The coating will last for many years with reasonable care, but expect high-contact areas (like a watch clasp) to eventually show signs of polishing or wear.

- If your primary focus is industrial performance (e.g., tools): PVD dramatically extends the life and performance of a tool, but it should be viewed as a high-performance, wearable surface that will eventually succumb to extreme use.

Ultimately, the lifespan of a PVD coating is a direct reflection of the physical demands placed upon it.

Summary Table:

| Aspect | PVD Coating Characteristic |

|---|---|

| Bonding Type | Molecular bond to the substrate |

| Primary Wear Mechanism | Slow abrasion from friction, not peeling |

| Typical Lifespan | 10+ years to a lifetime, depending on use |

| Repairability | Cannot be touched up; requires complete stripping and recoating |

Ready to enhance your product's durability and performance with a PVD coating that lasts?

KINTEK specializes in advanced PVD coating solutions for laboratory equipment, tools, and precision components. Our coatings provide extreme hardness and corrosion resistance, extending the life and reliability of your products.

Contact our experts today to discuss how our PVD coating services can add value to your application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition