Yes, unequivocally. Silicon Carbide (SiC) possesses a significantly high thermal conductivity, roughly three times that of conventional silicon (Si). This superior thermal performance is a cornerstone of its value, enabling SiC-based devices to operate at higher power densities and temperatures where silicon would fail.

The core takeaway is not just that SiC has high thermal conductivity, but that this property is highly variable. It depends critically on the material's purity, crystal structure (polytype), and operating temperature, making a deep understanding of these factors essential for effective thermal management.

Why Thermal Conductivity is a Decisive Factor

In power electronics, heat is the primary enemy of performance and reliability. The ability of a material to conduct heat away from the active region of a device dictates how much power it can handle.

The Problem of Self-Heating

High-power devices generate intense, localized heat during operation. If this heat cannot be evacuated efficiently, the internal temperature rises rapidly.

The Impact on Performance and Reliability

Excessive temperature degrades device performance, reduces its operational lifespan, and can lead to catastrophic failure. A material with high thermal conductivity acts like a highway for heat, moving it away from the critical junction to the heat sink.

Enabling Higher Power Density

Because SiC removes heat so effectively, components can be made smaller and packed closer together without overheating. This directly enables the creation of more compact, lightweight, and powerful electronic systems, from electric vehicle inverters to data center power supplies.

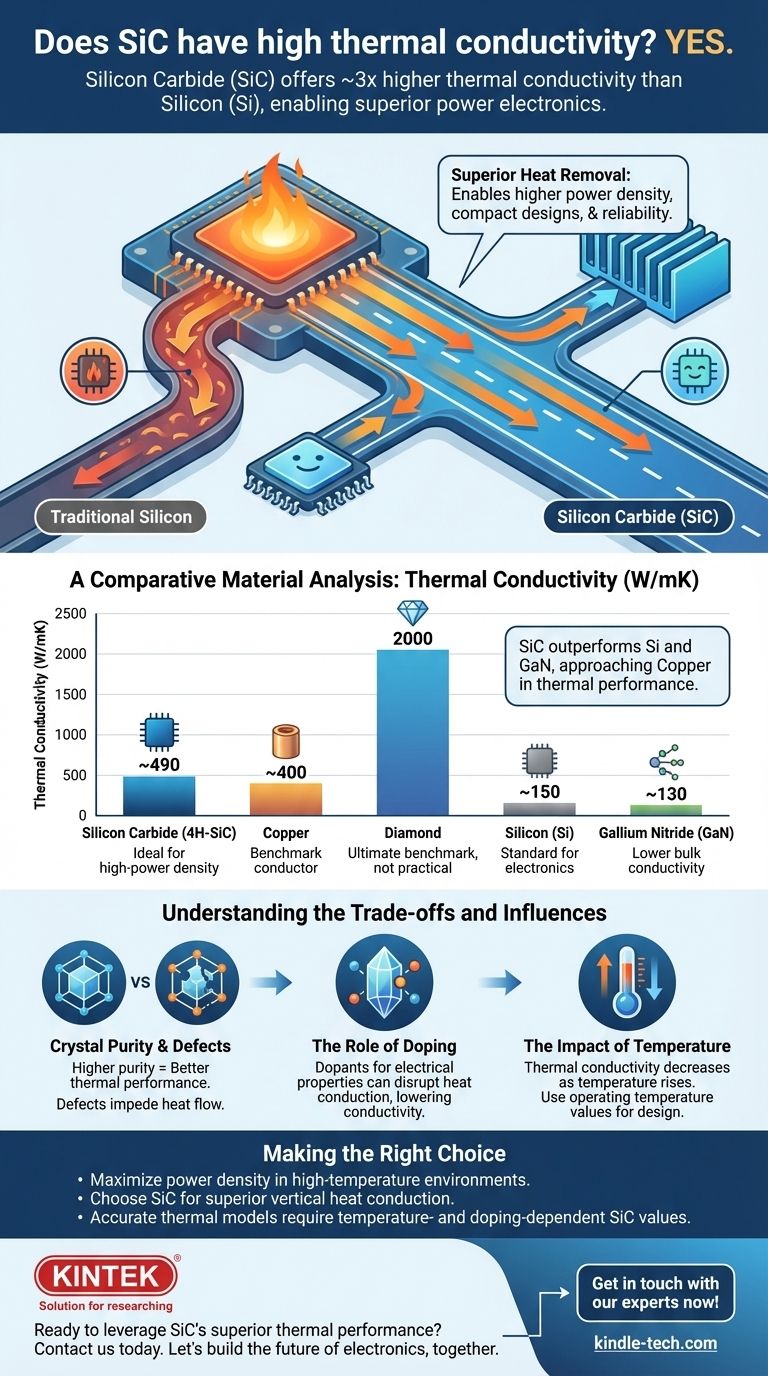

A Comparative Material Analysis

To truly appreciate SiC's thermal properties, it's essential to compare it to other key materials used in electronics. The unit of measure is Watts per meter-Kelvin (W/mK).

SiC vs. Silicon (Si)

This is the most critical comparison. While standard silicon sits at around 150 W/mK, high-quality single-crystal 4H-SiC can reach 490 W/mK. This threefold improvement is a fundamental reason for switching from Si to SiC in demanding applications.

SiC vs. Gallium Nitride (GaN)

Gallium Nitride, another leading wide-bandgap semiconductor, has a lower bulk thermal conductivity, typically around 130 W/mK. While GaN offers advantages in very high-frequency applications, SiC's superior thermal management is a key differentiator, especially in high-power modules.

SiC vs. Metals (Copper)

For perspective, copper—a material used specifically for heat sinks and conductors—has a thermal conductivity of around 400 W/mK. That high-purity SiC can approach and even exceed this value is remarkable for a semiconductor material.

The Diamond Benchmark

Diamond is the ultimate thermal conductor, with values exceeding 2000 W/mK. While not a practical semiconductor for most power applications, it serves as a useful benchmark to frame the excellent performance of SiC.

Understanding the Trade-offs and Influences

SiC's thermal conductivity is not a single, static number. Engineers must understand the factors that influence it to design reliable systems.

Crystal Purity and Defects

The primary carriers of heat in SiC are lattice vibrations, or phonons. Crystal defects, impurities, and grain boundaries act as scattering sites that impede the flow of these phonons, thereby lowering thermal conductivity. Higher material purity directly translates to better thermal performance.

The Role of Doping

Introducing dopants like nitrogen or aluminum is necessary to create the semiconductor's electrical properties. However, these dopant atoms also disrupt the perfect crystal lattice, creating additional phonon scattering. This means there is an inherent trade-off: heavily doped regions of a device will have a lower thermal conductivity.

The Impact of Temperature

Crucially, the thermal conductivity of SiC is temperature-dependent. As the device heats up, phonon-phonon scattering increases, which reduces the material's ability to conduct heat. A device designer must use a thermal conductivity value that reflects the actual operating temperature, not the value at room temperature.

Making the Right Choice for Your Application

Your material choice and design strategy must be guided by the specific thermal and electrical demands of your project.

- If your primary focus is maximum power density in high-temperature environments: SiC is a superior choice over silicon, as its ability to dissipate heat and withstand high temperatures is a core advantage.

- If you are choosing between SiC and GaN for a power module: Recognize SiC's inherent advantage in vertical heat conduction through the substrate, making it a robust choice for high-power, high-voltage applications.

- If you are creating thermal models for a device: You must use temperature-dependent and doping-dependent thermal conductivity values for SiC to ensure your simulations accurately predict real-world performance.

Ultimately, leveraging Silicon Carbide's exceptional thermal properties is the key to unlocking its full potential in next-generation power electronics.

Summary Table:

| Material | Typical Thermal Conductivity (W/mK) | Key Context |

|---|---|---|

| Silicon Carbide (4H-SiC) | ~490 | 3x better than silicon; ideal for high-power density |

| Silicon (Si) | ~150 | Standard for many electronics; lower thermal limit |

| Gallium Nitride (GaN) | ~130 | Excellent for high-frequency; lower thermal conductivity than SiC |

| Copper | ~400 | Benchmark for conductors; SiC performance is comparable |

| Diamond | >2000 | Ultimate benchmark; not practical for most semiconductor devices |

Ready to leverage SiC's superior thermal performance in your next project?

At KINTEK, we specialize in the lab equipment and consumables essential for developing and testing advanced materials like Silicon Carbide. Whether you are prototyping new power electronics or optimizing thermal management systems, our expertise and products support your innovation from R&D to production.

Contact us today to discuss how we can help you achieve higher power densities and greater reliability. Let's build the future of electronics, together.

Get in touch with our experts now!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How much temperature can porcelain withstand? Unlock Its True Heat Resistance & Avoid Thermal Shock

- What is the heating rate for alumina? Achieve Perfect Sintering and Avoid Cracking

- What is the strength of dental ceramics? Mastering the Compressive vs. Tensile Force Balance

- What is the thermal resistance of SiC? Understanding Its High Thermal Conductivity for Superior Performance

- What is the thermal stability of SiC? Withstand Extreme Heat Up to 2700°C

- What are the properties of ceramic surfaces? Discover Their Extreme Hardness and Stability

- What is the specific heat of alumina? It's a range from 451 to 955 J/kg·K

- How is the poor thermal-shock resistance of pure alumina typically mitigated? Improve Durability with Alumino-Silicates