Yes, absolutely. Chemical Vapor Deposition (CVD) is a sophisticated and widely used method for producing high-quality, lab-grown diamonds. This process essentially "grows" a diamond atom by atom from a gas mixture, allowing for exceptional control over the final product's properties without the extreme conditions required by other methods.

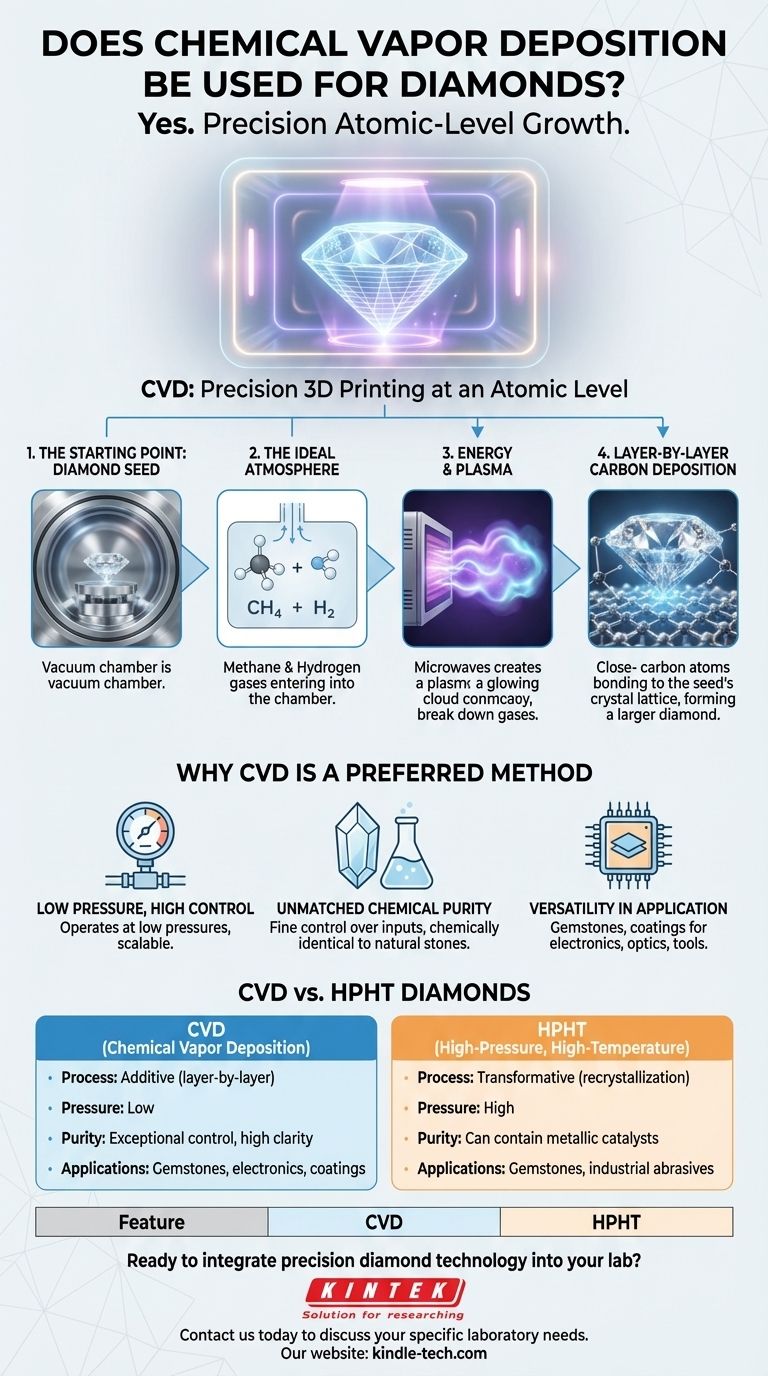

At its core, Chemical Vapor Deposition is less like mimicking the Earth’s brute force and more like precision 3D printing at an atomic level. It builds a real diamond layer by layer from a carbon-rich gas, offering a high degree of control over purity and form.

How CVD "Grows" a Diamond from Gas

The CVD process transforms a simple gas into one of the hardest materials on Earth. It is a method of addition, where a diamond crystal is systematically built up over time in a highly controlled environment.

The Starting Point: A Diamond Seed

The process begins with a "seed," which is typically a very thin, high-quality slice of an existing diamond. This seed is placed inside a sealed vacuum chamber and acts as the foundation upon which the new diamond will grow.

Creating the Ideal Atmosphere

Once the seed is in place, the chamber is evacuated to a near-perfect vacuum to remove any potential contaminants. It is then filled with a precise mixture of gases, primarily a carbon-rich gas like methane and pure hydrogen.

The Role of Energy and Plasma

This gas mixture is energized, often using microwaves, which heats the chamber and breaks down the gas molecules. This creates a "plasma," a cloud of charged particles that includes elemental carbon and atomic hydrogen.

Layer-by-Layer Carbon Deposition

Within this plasma, the carbon atoms are drawn to the cooler diamond seed. They bond to the seed's crystal lattice, perfectly replicating its structure. This deposition occurs atom by atom, slowly building the diamond layer upon layer. The atomic hydrogen plays a crucial role by selectively etching away any non-diamond carbon, ensuring high purity.

Why CVD is a Preferred Method

While not the only method for creating diamonds, CVD has become a dominant technology due to several key advantages over the older High-Pressure, High-Temperature (HPHT) process.

Low Pressure, High Control

Unlike the HPHT method, which simulates the crushing forces deep within the Earth, CVD operates at very low pressures. This simplifies the required equipment and makes the manufacturing process more manageable and scalable.

Unmatched Chemical Purity

The CVD environment allows for fine control over the chemical inputs. This makes it possible to grow exceptionally pure diamonds that are chemically identical to the finest natural stones. Other elements can be intentionally excluded, avoiding impurities like nitrogen that can cause yellowing.

Versatility in Application

CVD is not limited to growing gemstone-sized crystals. The technology can be used to apply an ultra-hard diamond coating over large areas and on various materials (substrates). This versatility is critical for technological advancements in electronics, optics, and cutting tools.

Key Distinctions: CVD vs. HPHT Diamonds

Understanding the difference between the two primary lab-growth methods clarifies why CVD is often chosen.

The Growth Environment

CVD uses a low-pressure gas plasma to deposit carbon atoms onto a seed. In contrast, HPHT subjects a carbon source (like graphite) to immense pressure and heat, using a molten metal catalyst to dissolve the carbon and recrystallize it into a diamond.

The Growth Process

CVD is an additive process, building the diamond up layer by layer. This can sometimes result in distinct, identifiable growth patterns. HPHT is a transformative process, forcing a complete recrystallization of the carbon source in a high-pressure press.

Resulting Crystal Form

Because of the layer-by-layer growth, CVD is excellent for producing large, flat crystals ideal for both gemstones and industrial applications. HPHT growth occurs in a more constrained environment, often producing crystals with a different fundamental shape.

Making the Right Choice for Your Goal

Both CVD and HPHT produce real diamonds with the same physical and chemical properties as mined diamonds. The choice often depends on the specific application and desired outcome.

- If your primary focus is exceptional purity and color: CVD offers precise control over the growth environment, making it a leading choice for producing high-clarity, colorless gemstones.

- If your interest is in technological applications: CVD's ability to coat various materials and grow large, uniform wafers makes it the definitive choice for most industrial and electronic uses.

- If you are comparing lab-grown options: Recognize that both are scientifically valid methods, but their distinct processes create different microscopic characteristics that a gemologist can identify.

Ultimately, CVD technology represents a fundamental shift from mining diamonds to engineering them with atomic-level precision.

Summary Table:

| Feature | CVD Diamonds | HPHT Diamonds |

|---|---|---|

| Process | Additive (layer-by-layer) | Transformative (recrystallization) |

| Pressure | Low | High |

| Purity | Exceptional control, high clarity | Can contain metallic catalysts |

| Applications | Gemstones, electronics, coatings | Gemstones, industrial abrasives |

Ready to integrate precision diamond technology into your lab? KINTEK specializes in advanced lab equipment and consumables for materials science and research. Whether you're developing next-generation electronics or need high-purity materials, our expertise can help you achieve superior results. Contact us today to discuss how our solutions can support your specific laboratory needs.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings