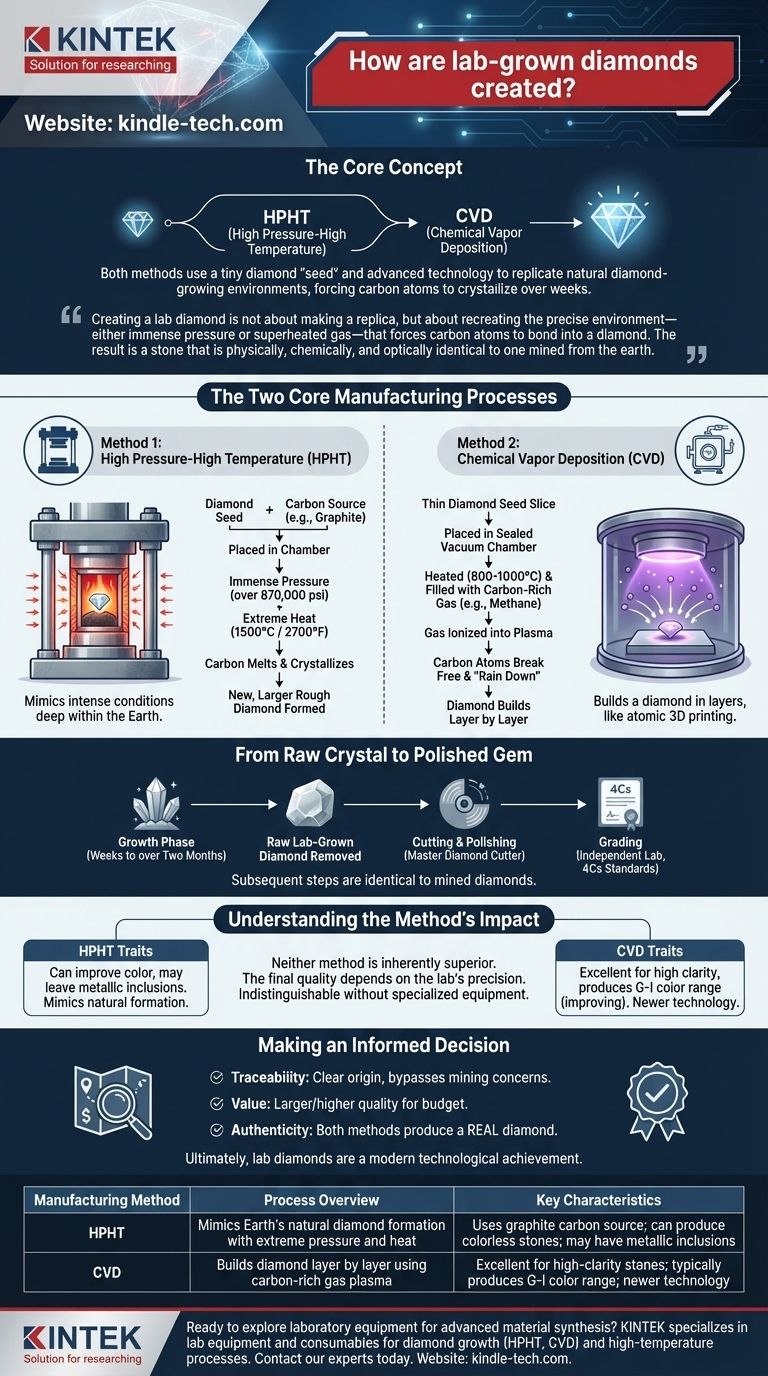

Lab-grown diamonds are created using two primary manufacturing methods: High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Both processes start with a tiny diamond "seed" and use advanced technology to replicate the natural diamond-growing environment, forcing carbon atoms to crystallize into a diamond structure over a matter of weeks.

At its core, creating a lab diamond is not about making a replica, but about recreating the precise environment—either immense pressure or superheated gas—that forces carbon atoms to bond into a diamond. The result is a stone that is physically, chemically, and optically identical to one mined from the earth.

The Two Core Manufacturing Processes

While a natural diamond takes millions of years to form deep within the Earth's mantle, technology has allowed us to accelerate this process dramatically. The two dominant methods achieve this in different ways.

Method 1: High Pressure-High Temperature (HPHT)

The HPHT method directly mimics the intense conditions found deep within the earth.

A small diamond seed is placed into a chamber along with a pure, solid carbon source, such as graphite.

This chamber is then subjected to immense pressures (over 870,000 pounds per square inch) and extreme heat (around 1500°C / 2700°F).

Under these conditions, the solid carbon source melts and crystallizes around the diamond seed, forming a new, larger rough diamond.

Method 2: Chemical Vapor Deposition (CVD)

The CVD method builds a diamond in layers, almost like atomic 3D printing. It is a newer technique compared to HPHT.

A thin slice of a diamond seed is placed inside a sealed vacuum chamber.

The chamber is heated to a high temperature (around 800-1000°C) and filled with a mixture of carbon-rich gases, like methane.

This high heat ionizes the gases into a plasma, which causes carbon atoms to break free. These carbon atoms then "rain down" and deposit onto the diamond seed, building the diamond layer by layer.

From Raw Crystal to Polished Gem

The creation process does not end when the crystal stops growing. The subsequent steps are identical to those for a mined diamond, demonstrating that the final product is the same material.

The Growth Phase

Depending on the desired size and quality, the growth process for a single gem-quality diamond can take anywhere from several weeks to over two months.

This controlled, steady growth is critical for achieving the high clarity and desired color characteristics of a beautiful gemstone.

Cutting, Polishing, and Grading

Once the rough lab-grown diamond is formed, it is removed from the growth chamber. It is then sent to a master diamond cutter who plans, cuts, and polishes the stone to maximize its brilliance and beauty.

After polishing, the diamond is sent to an independent gemological laboratory to be graded on the exact same standards as natural diamonds—the 4Cs of Cut, Color, Clarity, and Carat.

Understanding the Method's Impact

While both HPHT and CVD produce real diamonds, the different growth environments can leave subtle microscopic clues and influence the final characteristics of the rough stone.

Inherent Traits of Each Method

CVD diamonds historically tended to be produced in the warmer G-I color range, though technology is constantly improving this. The process is excellent for producing very high-clarity stones.

HPHT can be used to improve the color of some diamonds (both lab-grown and natural) after they are grown, turning brownish stones into colorless ones. However, the process can sometimes leave trace metallic inclusions from the growth cell.

Why the Method Doesn't Affect Authenticity

Neither method is inherently superior; they are simply different paths to the same result. The final quality of the diamond depends on the precision of the specific lab's process and the skill of the diamond cutter.

Without highly specialized gemological equipment, it is impossible to distinguish a lab-grown diamond from a natural one, let alone tell which method was used to create it.

Making an Informed Decision

Understanding the manufacturing process demystifies the product, allowing you to focus on what matters most for your specific goals.

- If your primary focus is traceability: A lab-grown diamond provides a clear, documented origin, bypassing the environmental and ethical concerns associated with mining.

- If your primary focus is value: The efficiency of the lab process means you can typically acquire a larger or higher-quality diamond for a given budget compared to a natural stone.

- If your primary focus is authenticity: Rest assured that both HPHT and CVD produce a real diamond. The choice of growth method does not change the fact that the final product is a genuine carbon crystal.

Ultimately, understanding how lab diamonds are made empowers you to see them not as an alternative, but as a modern technological achievement.

Summary Table:

| Manufacturing Method | Process Overview | Key Characteristics |

|---|---|---|

| High Pressure-High Temperature (HPHT) | Mimics Earth's natural diamond formation with extreme pressure and heat | Uses graphite carbon source; can produce colorless stones; may have metallic inclusions |

| Chemical Vapor Deposition (CVD) | Builds diamond layer by layer using carbon-rich gas plasma | Excellent for high-clarity stones; typically produces G-I color range; newer technology |

Ready to explore laboratory equipment for advanced material synthesis? KINTEK specializes in lab equipment and consumables, serving researchers and manufacturers who need reliable solutions for diamond growth and other high-temperature processes. Whether you're developing CVD systems or HPHT technology, our expertise can help you achieve precise, repeatable results. Contact our experts today to discuss how we can support your laboratory's specific needs in materials science and gemstone synthesis.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What are the characteristics and applications of MPCVD? Discover the Secret to High-Purity Lab-Grown Diamonds

- What are the cons of lab diamonds? Understanding the Financial and Perceptual Drawbacks

- How do scientists grow diamonds? Replicating Nature's Process in a Lab

- What is chemical vapor deposition of diamond? Grow High-Purity Diamonds Atom-by-Atom

- Can diamond be made artificially? Yes, with Identical Quality to Natural Diamonds

- What are the industrial uses of CVD diamond? Unlock Extreme Performance in Your Applications

- What is the difference between CVD diamond and natural diamond? A Guide to Making an Informed Choice

- How long does a diamond take to create? From Billions of Years to a Few Weeks