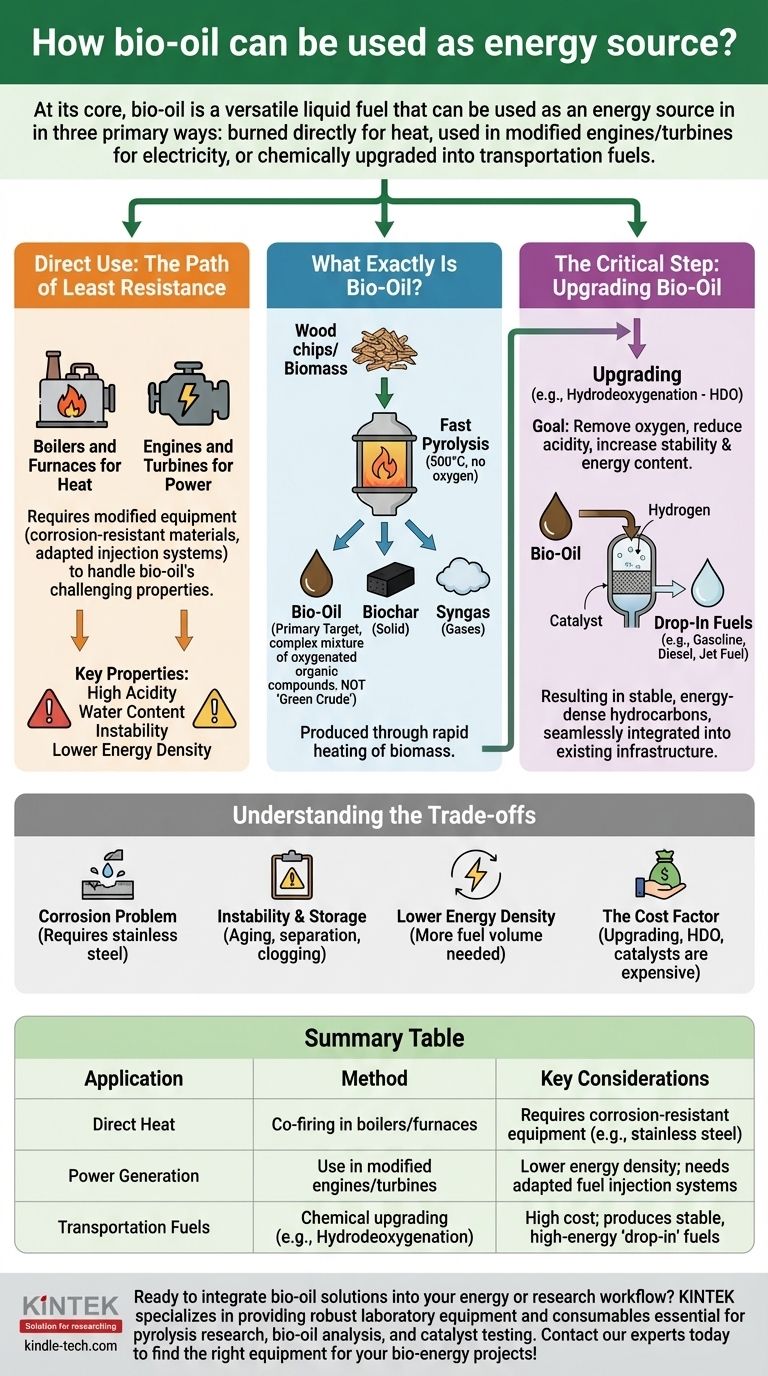

At its core, bio-oil is a versatile liquid fuel that can be used as an energy source in three primary ways: it can be burned directly for heat in boilers and furnaces, used in modified engines and turbines to generate electricity, or chemically upgraded into higher-quality transportation fuels like gasoline and diesel.

Bio-oil holds significant promise as a renewable energy source derived from biomass, but it is not a direct "drop-in" replacement for fossil fuels. Its challenging chemical properties—high acidity, water content, and instability—mean it must either be used in specially modified equipment or undergo significant processing to become a practical, stable fuel.

What Exactly Is Bio-Oil?

To understand how to use bio-oil, you must first understand what it is. It is not simply "liquid wood"; it's a complex mixture of oxygenated organic compounds with properties very different from conventional crude oil.

The Pyrolysis Process

Bio-oil is produced through a process called fast pyrolysis. This involves rapidly heating organic biomass (like wood chips, agricultural waste, or algae) to around 500°C in the absence of oxygen.

This process thermally decomposes the biomass into three products: bio-oil (a liquid), biochar (a solid charcoal-like substance), and syngas (a mixture of flammable gases). The liquid bio-oil is the primary target for energy applications.

Key Properties: Not a "Green Crude"

Crude bio-oil is fundamentally different from petroleum crude. It has a high water content (15-30%), is highly acidic (pH of 2-3), and contains a large amount of oxygen.

These properties make it corrosive, thermally unstable, and give it a lower heating value (energy content) compared to fossil fuels. These characteristics dictate how it can be used.

Direct Use: The Path of Least Resistance

Using bio-oil directly is the simplest approach, but it requires specialized or modified equipment to handle its challenging properties.

Boilers and Furnaces for Heat

The most straightforward application is co-firing raw bio-oil with conventional fuels (like fuel oil or natural gas) in industrial boilers or furnaces.

This generates heat for industrial processes or district heating. However, the equipment's fuel lines, pumps, and atomizers must be made of corrosion-resistant materials like stainless steel.

Engines and Turbines for Power

Bio-oil can also be used in stationary diesel engines or gas turbines to generate electricity. This is more complex than using it for heat.

The fuel injection systems must be modified to handle its higher viscosity and acidity. Due to its lower energy density, more fuel volume is needed to produce the same power output as diesel.

The Critical Step: Upgrading Bio-Oil

For most high-value applications, especially transportation, raw bio-oil must be chemically processed or "upgraded" to improve its quality and stability.

Why Upgrading is Necessary

Upgrading aims to solve bio-oil's core problems. The primary goals are to remove oxygen, reduce acidity, increase stability, and boost its energy content.

This process transforms the unstable, corrosive liquid into a more conventional hydrocarbon fuel that resembles crude oil and can be processed in existing refineries.

Common Upgrading Techniques

The most common method for upgrading is a catalytic process called hydrodeoxygenation (HDO), also known as hydrotreating.

In this process, bio-oil is reacted with hydrogen at high pressure and temperature in the presence of a catalyst. This removes oxygen atoms (as water) and saturates unstable compounds, creating a stable, energy-dense hydrocarbon liquid.

The Goal: Creating Drop-In Fuels

The ultimate goal of upgrading is to produce "drop-in" fuels. These are biofuels that are chemically indistinguishable from their fossil-fuel counterparts, like renewable gasoline, diesel, or jet fuel.

These fuels can be seamlessly integrated into the existing fuel distribution infrastructure, including pipelines, storage tanks, and vehicle engines, without any modifications.

Understanding the Trade-offs

While promising, the path from biomass to usable energy via bio-oil involves significant challenges and compromises.

The Corrosion Problem

The high acidity of raw bio-oil is its most significant technical barrier. It aggressively corrodes common materials like carbon steel and aluminum, requiring expensive stainless steel or other resistant alloys for storage and transport.

Instability and Storage Challenges

Over time, raw bio-oil thickens and can even separate into different phases, a process known as aging. This makes long-term storage difficult and can clog fuel lines and filters.

Lower Energy Density

Raw bio-oil contains only about 50-70% of the energy content of conventional fuel oil by volume. This means larger storage tanks and higher flow rates are needed to deliver the same amount of energy.

The Cost Factor

Both the pyrolysis process and, more significantly, the upgrading process (especially HDO) are energy-intensive and expensive. The cost of catalysts and the need for a hydrogen supply add to the final price of the upgraded fuel.

Making the Right Choice for Your Application

The best way to use bio-oil depends entirely on the intended goal, balancing complexity, cost, and fuel quality.

- If your primary focus is stationary heat generation: Co-firing raw bio-oil in a modified industrial boiler is the most direct and cost-effective approach.

- If your primary focus is generating electricity in a remote location: Using bio-oil in a specially adapted stationary diesel engine can be viable, especially if biomass is readily available.

- If your primary focus is producing high-quality transportation fuel: A multi-stage process of pyrolysis followed by catalytic upgrading is necessary to create stable, energy-dense drop-in fuels.

Ultimately, harnessing bio-oil's potential requires a clear understanding of its inherent limitations and a targeted strategy to either accommodate them or eliminate them through processing.

Summary Table:

| Application | Method | Key Considerations |

|---|---|---|

| Direct Heat | Co-firing in boilers/furnaces | Requires corrosion-resistant equipment (e.g., stainless steel) |

| Power Generation | Use in modified engines/turbines | Lower energy density; needs adapted fuel injection systems |

| Transportation Fuels | Chemical upgrading (e.g., Hydrodeoxygenation) | High cost; produces stable, high-energy 'drop-in' fuels |

Ready to integrate bio-oil solutions into your energy or research workflow? KINTEK specializes in providing robust laboratory equipment and consumables essential for pyrolysis research, bio-oil analysis, and catalyst testing. Whether you are developing new upgrading processes or analyzing fuel properties, our precise tools help you achieve accurate and reliable results. Contact our experts today to find the right equipment for your bio-energy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time