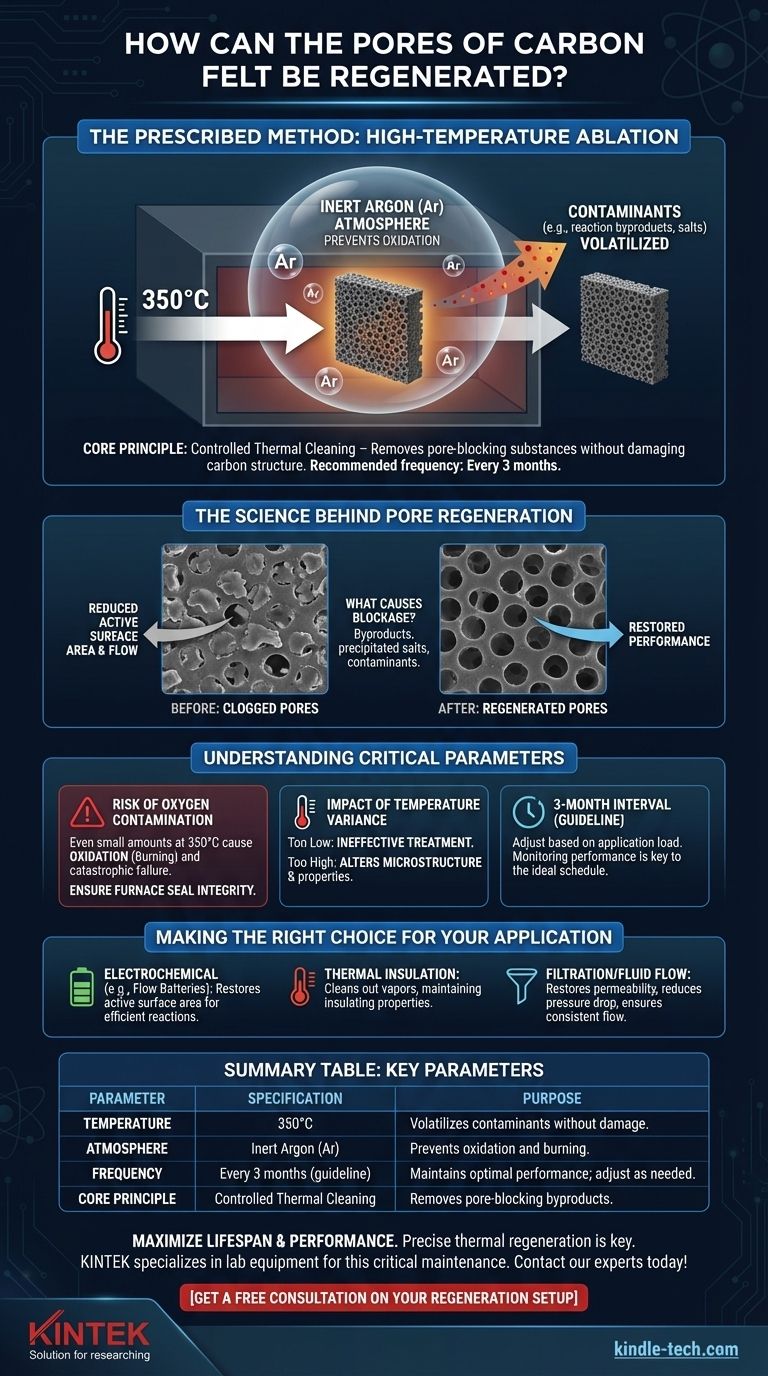

The prescribed method for regenerating the pores of carbon felt is through a process of high-temperature ablation. This procedure involves heating the material to 350°C within an inert Argon (Ar) atmosphere, a cycle typically recommended every three months to restore performance.

The core principle of regeneration is not simply heating, but controlled thermal cleaning. Using a specific temperature in an inert environment removes contaminants that block the felt's pores without oxidizing or damaging the underlying carbon structure.

The Science Behind Pore Regeneration

To properly execute this procedure, it is essential to understand the scientific principles at play. The goal is to reverse the degradation that occurs during operational use.

What Causes Pore Blockage?

Carbon felt's high porosity is key to its function in applications like flow batteries or high-temperature insulation. Over time, these microscopic pores can become clogged with reaction byproducts, precipitated salts, or other contaminants, reducing the active surface area and impeding flow.

This blockage is a primary driver of performance degradation, leading to decreased efficiency and a shorter operational lifespan for the component.

The Role of High Temperature

The specified temperature of 350°C is high enough to induce thermal decomposition or volatilization of many common organic and inorganic contaminants. This process, known as ablation in this context, effectively "bakes off" the unwanted material, clearing the blocked pores.

The temperature is carefully selected to be aggressive enough for cleaning but not so high that it alters the fundamental structure of the carbon felt itself.

Why an Inert Argon Atmosphere is Critical

Heating carbon in the presence of oxygen would cause it to oxidize, or burn, completely destroying the felt. Using an inert gas like Argon is non-negotiable.

Argon displaces all oxygen from the furnace or chamber. This creates a protective, non-reactive environment where contaminants can be burned off without consuming the carbon felt, ensuring the material's structural integrity is preserved.

Understanding the Trade-offs and Key Parameters

Successful regeneration depends on precise control over the process. Deviating from the key parameters can lead to ineffective treatment or irreversible damage.

Risk of Oxygen Contamination

The most significant risk is an air leak into the heating chamber. Even small amounts of oxygen at 350°C can lead to pitting, degradation, or catastrophic failure of the carbon felt. Ensuring the integrity of the furnace seals is paramount.

The Impact of Temperature Variance

If the temperature is too low, contaminant removal will be incomplete, and the regeneration will be ineffective. If the temperature is too high, it can begin to alter the felt's microstructure, potentially impacting its mechanical properties and surface characteristics.

The 3-Month Regeneration Interval

The recommendation to regenerate every three months is a general guideline based on typical use cases. The optimal frequency depends entirely on your specific application.

Systems under heavy load or exposed to high concentrations of contaminants may require more frequent regeneration. Conversely, less demanding applications might extend this interval. Monitoring your system's performance is the best way to determine the ideal schedule.

Making the Right Choice for Your Application

Applying this regeneration process correctly is key to maximizing the lifespan and value of your carbon felt components.

- If your primary focus is electrochemical performance (e.g., flow batteries): This process is crucial for removing passivating films and byproducts, thereby restoring the active surface area needed for efficient reactions.

- If your primary focus is thermal insulation: Regeneration cleans out any condensed vapors or deposits that can increase the felt's thermal conductivity and compromise its insulating properties.

- If your primary focus is filtration or fluid flow: Clearing the pores is essential for restoring permeability, reducing pressure drop, and ensuring consistent flow rates through the material.

Mastering this thermal cleaning protocol enables you to reliably restore carbon felt components to near-original performance.

Summary Table:

| Key Parameter | Specification | Purpose |

|---|---|---|

| Temperature | 350°C | Volatilizes contaminants without damaging the carbon structure. |

| Atmosphere | Inert Argon (Ar) | Prevents oxidation and burning of the carbon felt. |

| Frequency | Every 3 months (guideline) | Maintains optimal performance; adjust based on application load. |

| Core Principle | Controlled Thermal Cleaning | Removes pore-blocking byproducts to restore surface area and flow. |

Maximize the lifespan and performance of your carbon felt components. The precise thermal regeneration process is key to maintaining efficiency in applications like flow batteries, thermal insulation, and filtration. KINTEK specializes in the lab equipment and consumables needed for this critical maintenance, including high-temperature furnaces with controlled atmospheres. Contact our experts today to ensure your regeneration protocol is perfectly tailored to your laboratory's specific needs.

Get a Free Consultation on Your Regeneration Setup

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

People Also Ask

- What temperature can alumina crucible withstand? A Guide to High-Temperature Stability and Safety

- What is the temperature range of alumina crucibles? Key Factors for Safe High-Temp Use

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container

- What are the advantages of selecting an alumina crucible for TGA? Ensure High-Precision Thermal Analysis Data

- What are the advantages of using alumina crucibles for the TGA of modified alkyd resins? Ensure Accurate Results