At its most fundamental level, a crucible is a specialized container designed to withstand extremely high temperatures. They are essential tools used across science and industry for processes like melting metals for casting, creating advanced alloys, recycling scrap, and performing high-purity chemical analyses.

A crucible is more than just a heat-proof bowl; it is a critical instrument whose material is carefully chosen to ensure the purity and integrity of the substance it holds, whether it's molten metal or a chemical sample for analysis.

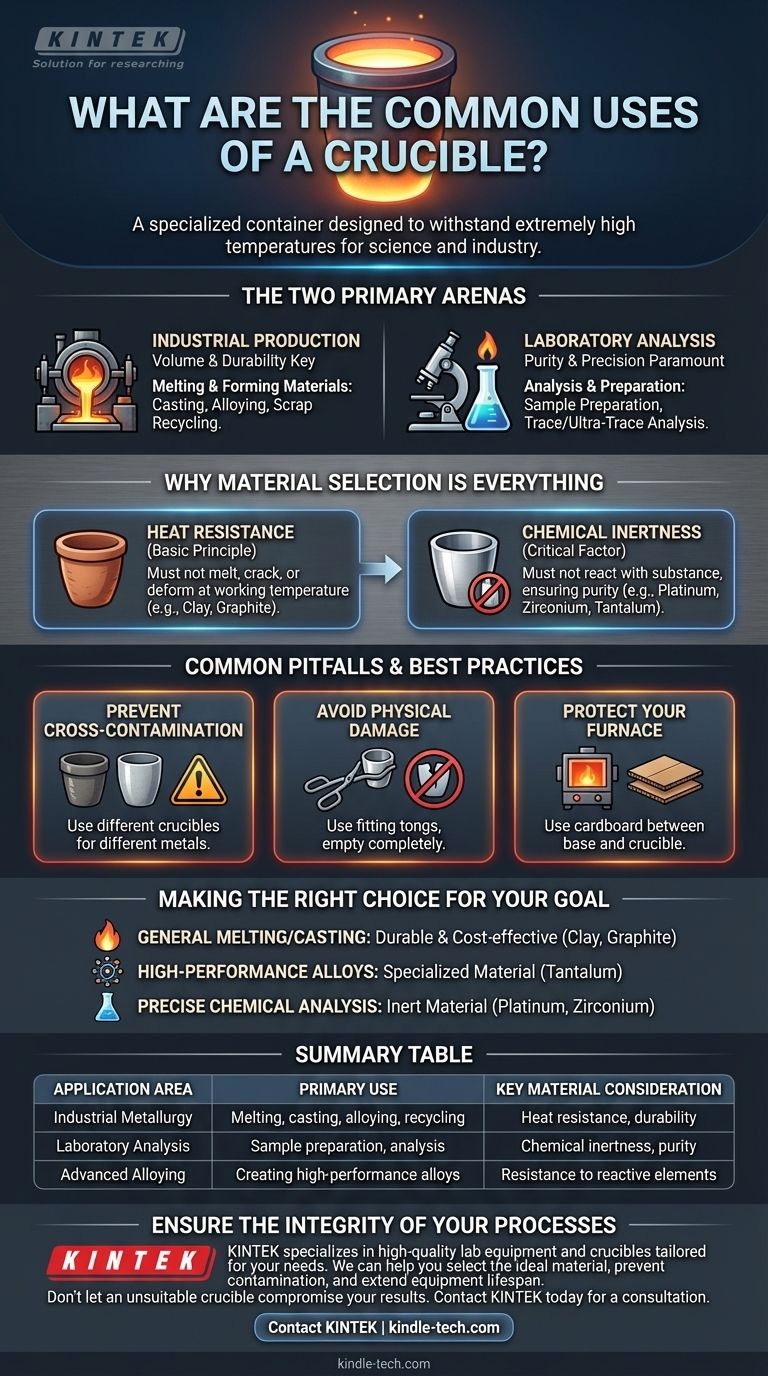

The Two Primary Arenas for Crucibles

A crucible's application can be broadly divided into two categories: industrial production, where volume and durability are key, and laboratory analysis, where purity and precision are paramount.

In Industry: Melting and Forming Materials

The most common industrial use of crucibles is for metallurgy. They are the vessels in which metals are heated past their melting point for various applications.

This includes casting, where molten metal is poured into a mold to create a specific part, and alloying, where different metals or powders are melted together to form a new material with enhanced properties. They are also used in smaller-scale scrap metal recycling.

In the Laboratory: Analysis and Preparation

In a lab setting, crucibles are indispensable for analytical chemistry. Their purpose is to hold a sample while it is heated, burned, or dissolved.

This is critical for sample preparation and for determining the precise chemical makeup of a substance, often down to trace and ultra-trace level constituents. Here, the crucible must not react with or contaminate the sample in any way.

Why Material Selection Is Everything

The specific job dictates the crucible's material. While all crucibles must resist heat, their chemical properties are often just as important.

The Basic Principle: Heat Resistance

Historically, crucibles were made from clay, a material that can withstand high temperatures and is relatively inexpensive. The primary requirement for any crucible is that it does not melt, crack, or deform at the working temperature of the furnace.

The Critical Factor: Chemical Inertness

For advanced applications, simple heat resistance is not enough. The crucible must be chemically inert, meaning it won't react with the substance inside it.

Materials like platinum, zirconium, and tantalum are used for this reason. They are essential when creating sensitive superalloys or when a chemist needs to be certain that the only elements detected in a sample are from the sample itself, not from the container.

Common Pitfalls and Best Practices

Using a crucible correctly is essential for safety, accuracy, and the longevity of the equipment. Mishandling can ruin an experiment or damage expensive hardware.

Preventing Cross-Contamination

A cardinal rule is to use different crucibles for different metals. Even microscopic residues from a previous melt can contaminate a new batch, altering the properties of an alloy or corrupting a chemical analysis.

Avoiding Physical Damage

Crucibles should only be handled with properly fitting tongs to prevent dropping or cracking them. Furthermore, they must be completely emptied after each use. Metal left to solidify can expand upon reheating, cracking the crucible from within.

Protecting Your Furnace

A simple but effective technique is to place a piece of cardboard between the furnace base and the crucible before heating. The cardboard burns away, leaving a thin layer of carbon that prevents the crucible from bonding to the furnace floor at high temperatures.

Making the Right Choice for Your Goal

Your objective determines the type of crucible you need. The choice is a balance between performance requirements and cost.

- If your primary focus is general metal melting or basic casting: A durable and cost-effective material like clay or graphite will likely suffice.

- If your primary focus is creating high-performance alloys: You need a specialized material like tantalum that can handle reactive metals at extreme temperatures without introducing impurities.

- If your primary focus is precise chemical analysis: An inert material like platinum or zirconium is non-negotiable to ensure the accuracy and purity of your results.

Ultimately, selecting the correct crucible is the foundational step in ensuring the success and integrity of any high-temperature process.

Summary Table:

| Application Area | Primary Use | Key Material Consideration |

|---|---|---|

| Industrial Metallurgy | Melting, casting, alloying, scrap recycling | Heat resistance, durability |

| Laboratory Analysis | Sample preparation, chemical analysis | Chemical inertness, purity |

| Advanced Alloying | Creating high-performance alloys | Resistance to reactive elements (e.g., Tantalum) |

Ensure the Integrity of Your High-Temperature Processes

Choosing the right crucible is critical for the success and safety of your work, whether in an industrial foundry or a research laboratory. KINTEK specializes in providing high-quality lab equipment and consumables, including a comprehensive range of crucibles tailored for specific applications and materials.

We can help you:

- Select the ideal crucible material (clay, graphite, platinum, zirconium, tantalum) for your specific process and temperature requirements.

- Prevent contamination and ensure purity in your metal melts or chemical analyses.

- Extend the lifespan of your equipment with proper usage guidelines and best practices.

Don't let an unsuitable crucible compromise your results. Let our experts guide you to the perfect solution for your laboratory or production needs.

Contact KINTEK today for a consultation and achieve superior process integrity.

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- Why are high-purity ceramic crucibles necessary for Pt/Pd alloys? Ensure Purity in High-Temperature Synthesis

- What are the advantages of using a graphite crucible? Ensure High Purity in Magnesium Vacuum Distillation

- What are the advantages of a crucible furnace? Achieve Versatile Melting with Precision and Control

- Why are alumina crucibles used as containers during the tungsten diffusion coating process on diamond surfaces?

- What precautions should be taken while heating and cooling the crucible? Prevent Thermal Shock and Ensure Safety

- What can I use instead of a crucible to melt gold? Avoid Dangerous Substitutes for Safe Melting

- What role does a corundum crucible play in TGA? Ensure High-Temperature Precision for Rock Sample Analysis

- What are the advantages of using high-purity alumina crucibles? Maximize LLZTO Cathode Performance & Material Purity