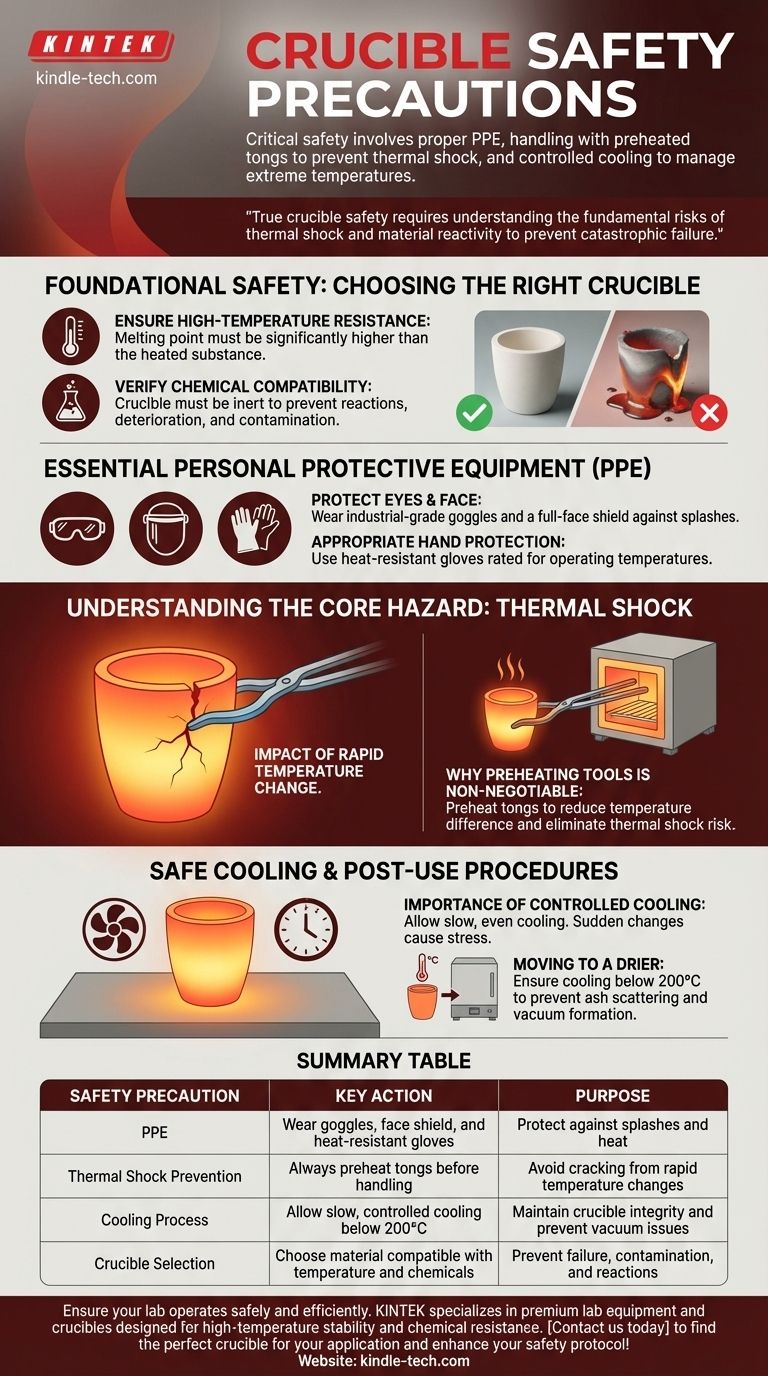

The most critical crucible safety precautions involve wearing proper personal protective equipment (PPE), handling the crucible only with preheated tongs to prevent thermal shock, and following a controlled cooling process after use. These measures are designed to manage the extreme temperatures and potential chemical reactions inherent in crucible work.

True crucible safety extends beyond simply following a checklist; it requires understanding the fundamental risks of thermal shock and material reactivity to prevent catastrophic failure before it happens.

Foundational Safety: Choosing the Right Crucible

Before you even begin, the most important safety decision is selecting the correct crucible for your specific application. Using an inappropriate crucible is a primary source of failure and danger.

Ensure High-Temperature Resistance

The crucible's material must have a melting point significantly higher than the substance you intend to heat. This prevents the crucible itself from melting, warping, or failing during the process.

Verify Chemical Compatibility

The crucible must be chemically inert and stable relative to the material it will hold. A reaction between the melt and the crucible can cause deterioration, contamination of your sample, and a potential breach.

Essential Personal Protective Equipment (PPE)

Working with crucibles and molten materials exposes you to extreme heat and potential splashes. Never proceed without adequate protection.

Protect Your Eyes and Face

Always wear industrial-grade safety goggles and a full-face shield. This is your primary defense against splashes of molten material or fragments from a fractured crucible.

Use Appropriate Hand Protection

Heat-resistant gloves rated for the temperatures you will be working with are mandatory. They protect you when handling equipment near the furnace and during the cleaning process.

Understanding the Core Hazard: Thermal Shock

The single greatest risk when handling a hot crucible is thermal shock. This occurs when a part of the crucible cools or heats much faster than another part, creating internal stresses that can cause it to crack or shatter violently.

The Impact of Rapid Temperature Change

Introducing a cold object, like room-temperature tongs, to a glowing hot crucible creates an immediate, localized temperature drop. This stress is often enough to cause catastrophic failure.

Why Preheating Tools is Non-Negotiable

You must preheat your crucible tongs for a few moments in the electric furnace or muffle furnace before touching the crucible. This simple step brings the tongs closer to the crucible's temperature, drastically reducing the risk of thermal shock.

Safe Cooling and Post-Use Procedures

Properly managing the crucible after the heating process is just as important as the heating itself.

The Importance of Controlled Cooling

After your work is complete, the crucible should be allowed to cool slowly and evenly. A sudden change in temperature, even from a cool breeze, can introduce thermal stress.

Moving to a Drier

If moving the crucible to a drier, ensure it has cooled to below 200°C first. This prevents residual ash from scattering and stops a strong vacuum from forming inside the drier, which can make the lid difficult or impossible to open.

Key Principles for Safe Operation

To ensure safety, focus on the principles behind the rules for your specific task.

- If your primary focus is preparation: Always begin by confirming your crucible's material is rated for the temperature and chemically compatible with your sample.

- If your primary focus is active handling: Make preheating your tongs an unbreakable habit to eliminate the primary risk of thermal shock.

- If your primary focus is post-procedure: Prioritize a slow, controlled cooling process to maintain the crucible's integrity for future use.

Ultimately, safe and effective crucible use is a direct result of understanding and respecting the materials and the extreme temperatures involved.

Summary Table:

| Safety Precaution | Key Action | Purpose |

|---|---|---|

| PPE | Wear goggles, face shield, and heat-resistant gloves | Protect against splashes and heat |

| Thermal Shock Prevention | Always preheat tongs before handling | Avoid cracking from rapid temperature changes |

| Cooling Process | Allow slow, controlled cooling below 200°C | Maintain crucible integrity and prevent vacuum issues |

| Crucible Selection | Choose material compatible with temperature and chemicals | Prevent failure, contamination, and reactions |

Ensure your lab operates safely and efficiently with the right equipment. KINTEK specializes in premium lab equipment and consumables, including crucibles designed for high-temperature stability and chemical resistance. Our products help you mitigate risks like thermal shock and ensure consistent results.

Contact us today to find the perfect crucible for your application and enhance your lab's safety protocol!

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What are the advantages of using a graphite crucible? Maximize Purity and Thermal Stability in Magnesium Reduction

- Why is Alumina Powder Filled at the Top of Crucibles in Sintering? Ensure Peak Oxidation Protection

- What can I use as a crucible to melt copper? Choose the right material for your furnace.

- What is the best material to use for a crucible? Match Your Metal to the Perfect Crucible

- What is the maximum temperature for clay crucibles? Find the Right Crucible for Your Melting Needs

- Can the same crucible be used for different metals? Avoid Costly Contamination and Crucible Failure

- Can you melt gold in a ceramic crucible? Discover the Right Crucible for Safe Melting

- What is the function of a crucible in chemistry? Withstand Extreme Heat for Pure Results